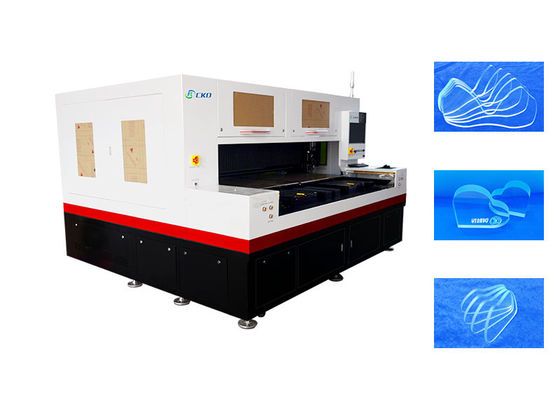

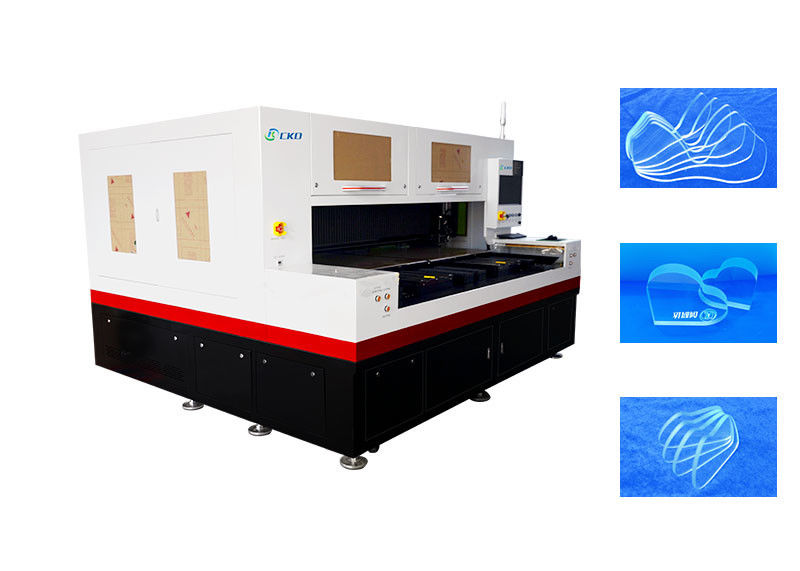

80w Thin Glass Fibre Laser Cutting Machine for Optical Assemblies

-

Highlight

80w Laser Glass Cutting Machine

-

NameFiber Laser Cutting Machine For Glass

-

Laser Power80w

-

Cutting Thickness0.03~19mm

-

Accuracy±0.01mm

-

Speed≤500mm/s

-

Chipping≤5μm

-

Place of OriginGuangdong, China

-

Brand NameCKD

-

CertificationISO / CE / FDI

-

Model NumberCC-GDA15

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-45 days

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability30 Sets Per Month

80w Thin Glass Fibre Laser Cutting Machine for Optical Assemblies

|

Picosecond Glass Cutting

Splitting Machine (All-in-One)

|

|

| This equipment is developed by the professional team of laser and automation industry for more than ten years . The equipment design uses high-quality imported durable parts , and the long-term production of the equipment is stable and reliable . Compared with CNC processing equipment , brittle materials have no taper picosecond laser cutting machine , no consumables in the production process , high production efficiency ( cutting speed up to 500mm/s , several times the processing efficiency of CNC ) , which saves manufacturing costs for processing manufacturers and improves product profits . |

|

|

Advantages

Irregular-shape High-speed cutting

High cutting quality, no taper,no burrs,small chipping

Low-cost,High-yield rate, Low consumables

and energy -saving

No pollution, No Powder and no wastewater

|

Materials

Ultra-clear glass, plain white polymer,

high borosilicate glass, quartz glass etc;

Phone glass cover, car glass ,

camera glass cover etc;

LCD screen,K9 glass, filter cutting, mirror cutting etc

|

![]()

| Significant Attribute | |

| X/Y movement speed | max. 500mm/s |

| Laser type | Infrared picosecond |

| Laser wavelength | 1064nm |

| Laser power | 30W/40W/75W/80W/90W optional |

| Pulse length | ≤10PS |

| Pulse frequency | 1Hz-1000kHz |

| Working mode | Laser XY moving |

| Cooling method | Water-cooled |

| Focusing mode | Cutting head |

| Focusing spot | ≤Ф3um |

| Cutting speed | Adjustable 0-500mm / s |

| Cutting thickness | according to the thickness of the glass to choose the number of laser W |

| Minimum cutting edge chipping | 6um |

| X / Y cutting stroke | 400mm x500mm (600X700mm 600X900 optional or customize a larger platform) |

| X/Y positioning accuracy | ≤±2μm |

| X/Y repeat positioning accuracy | ≤±1um |

![]()

Laser interferometer precision measurement

Equipment advantage

1 . Cutting thickness : achieve a knife cut 19mm thickness of white glass (15mm thickness of a knife, and mass production in the client so far)

2 . High efficiency : the cutting speed can be as high as 500mm/s, several times the processing efficiency of CNC, and dozens of times that of water knife. No secondary processing, small edge breakage, no washing, grinding, polishing and other secondary processing

3 . Smooth and flat , no damage : the edge is neat , good vertical , no micro-cracks , broken or debris

4 . High edge strength : three times that of traditional cutting methods

5 . Environmental protection without consumables : no contact cutting , energy saving and environmental protection

6 . Cutting precision ≤20µm , can flexibly achieve all kinds of glass abnormity cutting

| Samples of different shapes |

| Different thickness cases |

Q1: Could I visit your factory?

A1: Yes, We will warmly welcome you anytime. It's tooks about 1 hours from

bao'an International airport to our factory.

Q2: How many years do you do this business?

A2: From 2008.

Q3: Does your factory have the design & development capacities, we need customized products?

A3: yes. The staffs in our design department are well experienced in laser machine, with more than 5 to 10 years experience.

We can make customized products especially for you; Please kindly contact us for more details.

Q4: What is payment terms?

A4: 100% T/T advanced.

Q5: About shiping?

A5: 3-10 days after payment for standard products, please consult our sales for customized products.

Q6: How about your after service?

A6: Our engineers who has long time professional experience and sales will help you within 24h.

Q7: Do you have patents or core technology?

A7: Yes, for details, please contact our sales.

Q8: Where have you sold your products?

A8: Europe, Americas, Africa, and Asia.

If you have any questions, Please no hesitate to contact us. We will as always provide and feedback you the higher performance, cost-effective, better quality products and timely service.