60W 80W Automatic Laser Cutting Machine Glass For Electronic Chip Glass Sapphire

-

Highlight

Automatic Laser Cutting Machine 60W

,Automatic Laser Cutting Machine Glass

,Automatic Laser Cutting Machine 80W

-

NameAutomatic Laser Cutting Machine

-

Laser Power60W/80W

-

Cutting Thickness0-10mm

-

Key Selling PointsAutomatic

-

Weight (KG)2.5 Tons

-

Cutting Area600mm*900mm*2

-

Applicable MaterialAcrylic, Glass, Paper, Plastic, Crystal

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO

-

Model NumberCC-GD7

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-30 Work days

-

Payment TermsL/C, D/A, D/P, Western Union, T/T, MoneyGram

-

Supply Ability50 Sets Per Month

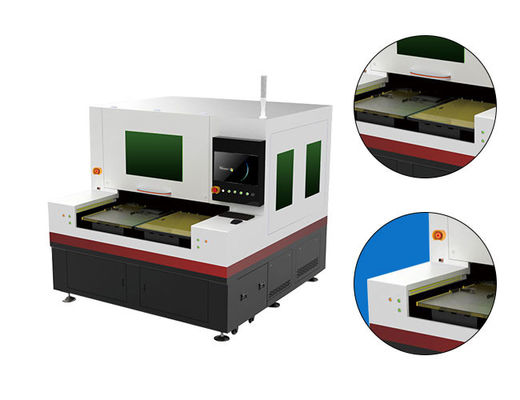

60W 80W Automatic Laser Cutting Machine Glass For Electronic Chip Glass Sapphire

Thin Glass Picosecond Laser Cutting Machine

Use For Electronic Chip Glass Sapphire

Products Description

1. Picosecond processing uses small single pulse energy, high frequency processing, fine carving, processing surface is more fine and smooth. There are three power options: 30W, 60W and 80W.

2. 600*700mm working width issuitable for most cutting scenes.

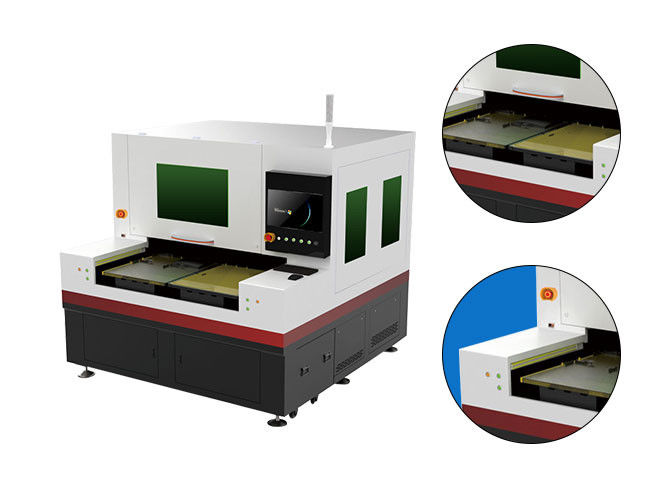

| Machine model | VBL6050 |

| Laser source power | 30W/60W/80W |

| Machine structure | X,Y,Z Marble Table |

| Max. stroke | 600mm*700mm*100mm |

| Re-positioning accuracy of motion platform | ±1um |

| positioning accuracy of motion platform | ±2um |

| Supported files | DXF,PLT,DWG |

| CCD Vision positioning accuracy | ±3um |

| Laser source wavelength | 1064nm |

| Beam quality | M²<1.3 |

| Minimum focus spot | ∅3um |

| Processing speed | 0-500mm/s adjustable |

| Cooling type | Constant temperature water cooling |

![]()

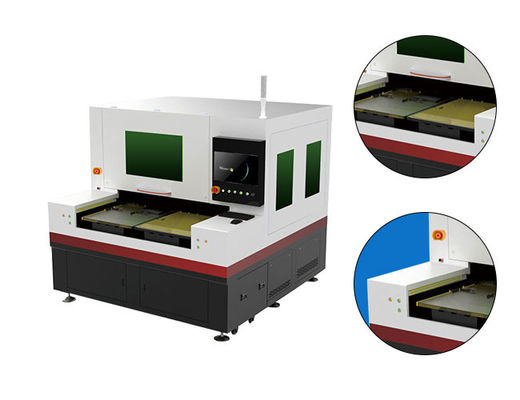

Processing advantage

1. Irregular-shape High-speed cutting

2. High cutting quality, no taper,no burrs,small chipping

3. Low-cost,High-yield rate, Low consumables and energy -saving

4. No pollution, No Powder and no wastewater

material used

1. Ultra clear class,plain white glass,

2. high borosilicate glass, quartz glass etc;

3. Phone glass cover, car glass , camera glass cover etc;

4. LCD screen,K9 glass, filter cutting, mirror cutting etc

![]()

To ensure precise and accurate cutting, the X/Y axis motor in our machine adopts high-end linear motor technology. This technology, coupled with the use of Germany 0.1um digital grating rulers, ensures reliable and precise positioning of the glass.