Thickness 0.1-25mm Laser Glass Cutting Machine Water Cooling 50HZ 60HZ

-

Highlight

25mm Laser Glass Cutting Machine

,Laser Glass Cutting Machine Water Cooling

,Laser Cutting Glass Machine 50HZ

-

NameLaser Glass Cutting Machine

-

Laser Power30/50/60/80w

-

Cutting Speed0-500mm/s

-

Cutting Accuracy±0.01mm

-

Working Voltage220V

-

Key Selling PointsUltra Fast Picesecond

-

Control SystemHTI Control

-

MaterialGlass

-

Cooling SystemWater Cooling

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO

-

Model NumberCC-GDA1

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden box

-

Delivery Time15-30 days

-

Payment TermsL/C, T/T

-

Supply Ability50 sets per month

Thickness 0.1-25mm Laser Glass Cutting Machine Water Cooling 50HZ 60HZ

High Frequency Laser Glass Cutting Machine with 0.1-25mm Cutting Thickness

Product Description:

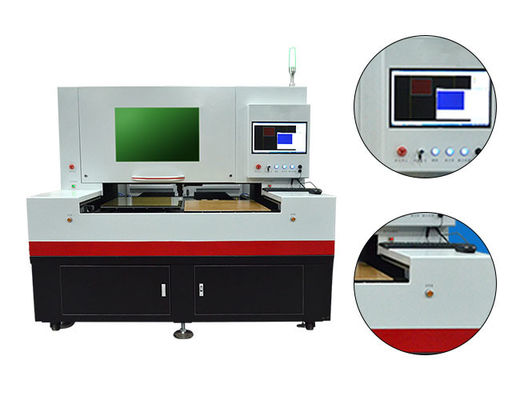

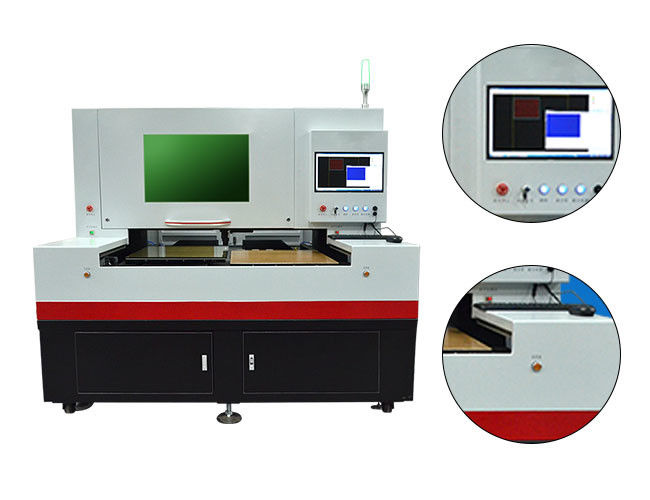

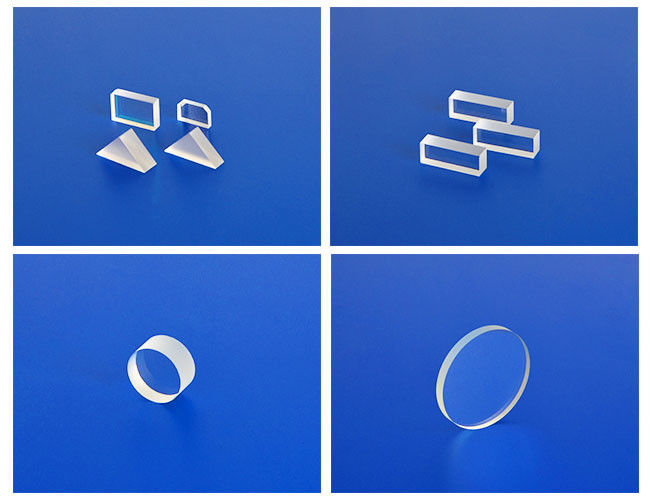

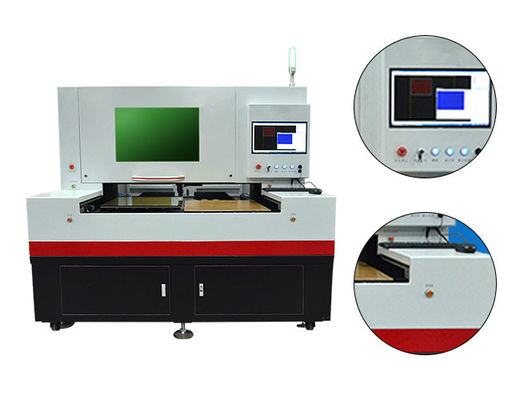

This Laser Glass Cutting Machine is specifically designed for thick glass processing, such as polygonal and irregular shapes. It is equipped with advanced infrared picosecond laser to ensure the cutting accuracy of ±0.01mm, and its adjustable laser power can support the cutting thickness from 0.1mm to 25mm. This machine is also equipped with a water cooling system that can rapidly reduce the temperature of the cutting surface and greatly reduce glass processing time. In addition, its rack and pinion transmission system provides smooth and reliable operation for the machine.

Features:

- Product Name: Laser Glass Cutting Machine

- Control System: HTI Control

- Laser Type: Infrared Picosecond

- Transmission System: Rack And Pinion

- Working Voltage: 220V

- Cutting Area: 400mm*500mm/ 600*700mm/ 600*900mm

- Specialty: Single Table Glass Cutting Machine, optical glass Laser Cutting Machine, colored glass cutting machine

Technical Parameters:

| Parameters | Stained Glass Cutting Machine |

|---|---|

| Material | Glass |

| Laser Power | 30/50/60/80w |

| Transmission System | Rack And Pinion |

| Working Frequency | 50HZ/60HZ |

| Working Environment | 26℃ |

| Cutting Thickness | 0.1-25mm |

| Working Voltage | 220V |

| Laser Type | Infrared Picosecond |

| Cutting Speed | 0-500mm/s |

| Cutting Accuracy | ±0.01mm |

| Parameters | Fiber Laser Cutting Machine |

|---|---|

| Material | Glass |

| Laser Power | 30/50/60/80w |

| Transmission System | Rack And Pinion |

| Working Frequency | 50HZ/60HZ |

| Working Environment | 26℃ |

| Cutting Thickness | 0.1-25mm |

| Working Voltage | 220V |

| Laser Type | Infrared Picosecond |

| Cutting Speed | 0-500mm/s |

| Cutting Accuracy | ±0.01mm |

| Parameters | High Precision Laser Cutting Machine |

|---|---|

| Material | Glass |

| Laser Power | 30/50/60/80w |

| Transmission System | Rack And Pinion |

| Working Frequency | 50HZ/60HZ |

| Working Environment | 26℃ |

| Cutting Thickness | 0.1-25mm |

| Working Voltage | 220V |

| Laser Type | Infrared Picosecond |

| Cutting Speed | 0-500mm/s |

| Cutting Accuracy | ±0.01mm |

Applications:

The CKD CC-GDA1 Laser Glass Cutting Machine is designed to meet the needs of various applications and scenarios, with a brand name of CKD, a model number of CC-GDA1, a place of origin of China, and an ISO certification. It has a minimum order quantity of 1, a price that can be negotiated, and a delivery time of 15-30 days. It has a payment terms of L/C, T/T, a supply ability of 50 sets per month, a working frequency of 50HZ/60HZ, a cutting area of 400mm*500mm/600*700mm/600*900mm, a laser type of infrared picosecond, a working environment of 26℃, and a cutting thickness of 0.1-25mm. It is suitable for packaging in a wooden box. It is a small glass laser cutting machine, an environmental protection glass laser cutting machine, a polygonal glass cutting machine, and a precise glass cutting machine.

Customization:

We provide optical glass Laser Cutting Machine, Single Table Glass Cutting Machine and High Precision Laser Cutting Machine with brand name CKD, model CC-GDA1. It is certified by ISO and minimum order quantity is 1. The price is negotiable. The packaging details are wooden box and the delivery time is 15-30 days. The payment terms are L/C or T/T. We have a supply ability of 50 sets per month. The cooling system is water cooling and the working frequency is 50HZ/60HZ. The laser type is infrared picosecond and the control system is HTI control. The laser power is 30/50/60/80w.

Support and Services:

We provide technical support and services for our Laser Glass Cutting Machine in order to ensure our customers have the best experience with their machine. We provide a 24/7 customer service hotline, as well as email and online support.

We also provide installation and maintenance services for our customers if needed. Our technicians can install and troubleshoot the machine to ensure that it works properly. We also provide regularly scheduled maintenance to ensure the longevity of the machine.

We also have a team of engineers available to answer any technical questions or provide assistance with any problems that may arise. We are always happy to help our customers get the most out of their machine.

Packing and Shipping:

For safe and secure packaging and shipping of Laser Glass Cutting Machine, we use high-quality and durable packaging materials that protect the machine from any damage during shipping.

The machine is securely placed in a wooden crate or carton, and then wrapped in foam to prevent any kind of shifting during the transit. The machine is also secured with straps for added stability.

The package is then sealed with a plastic wrap to protect it from any weather conditions.

The package is then labeled with all necessary information regarding the machine, such as the manufacturer, model number, and destination address.

The package is then ready for shipping via reliable and safe shipping carriers.

FAQ:

A1: The Brand Name of the Laser Glass Cutting Machine is CKD.

Q2: What is the Model Number of the Laser Glass Cutting Machine?

A2: The Model Number of the Laser Glass Cutting Machine is CC-GDA1.

Q3: Where is the Laser Glass Cutting Machine manufactured?

A3: The Laser Glass Cutting Machine is manufactured in China.

Q4: Does the Laser Glass Cutting Machine have an ISO certification?

A4: Yes, the Laser Glass Cutting Machine has an ISO certification.

Q5: What is the Minimum Order Quantity for the Laser Glass Cutting Machine?

A5: The Minimum Order Quantity for the Laser Glass Cutting Machine is 1.