CKD Tempered Glass Laser Cutting Machine 60W 80W With HTI Control

-

Highlight

Tempered Glass Laser Cutting Machine 60W

,Tempered Glass Laser Cutting Machine 80W

,80W Laser Cutting Machine Glass

-

NameTempered Glass Laser Cutting Machine

-

Cutting Speed0-500mm/s

-

MaterialGlass

-

Cutting Area400mm*500mm/ 600*700mm/ 600*900mm

-

Cutting Accuracy±0.01mm

-

Control SystemHTI Control

-

Cooling SystemWater Cooling

-

Key Selling PointsUltra Fast Picesecond

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO

-

Model NumberCC-GDA1

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden box

-

Delivery Time15-30 days

-

Payment TermsL/C, T/T

-

Supply Ability50 sets per month

CKD Tempered Glass Laser Cutting Machine 60W 80W With HTI Control

Working Frequency 50HZ/60HZ

Laser Glass Cutting Machine 0-500mm/s Cutting Speed

Product Description

Infrared picosecond laser refers to an ultra-short pulse laser with a wavelength in the infrared region, and the pulse width is generally in the picosecond level (10^-12 seconds).

Technical Parameters:

| Attribute | Parameter |

|---|---|

| Working Voltage | 220V |

| Working Environment | 26℃ |

| Material | Glass |

| Laser Type | Infrared Picosecond |

| Cutting Area | 400mm*500mm/ 600*700mm/ 600*900mm |

| Working Frequency | 50HZ/60HZ |

| Control System | HTI Control |

| Cutting Thickness | 0.1-25mm |

| Key Selling Points | Ultra Fast Picesecond |

| Laser Power | 30W/50W/60W/80W |

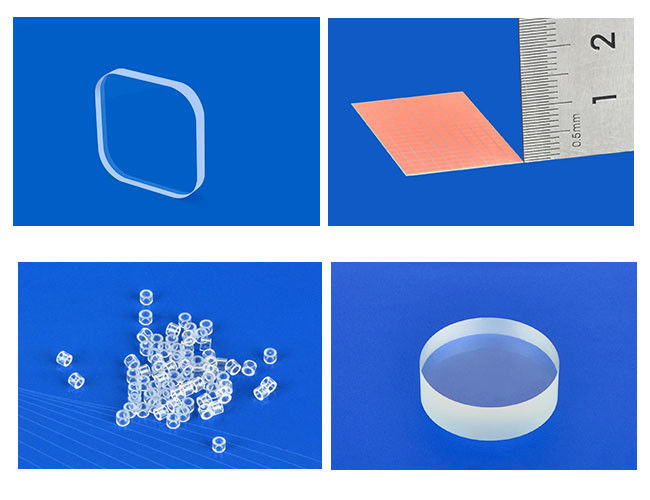

| Specialty | Small glass laser cutting machine, Thick glass laser cutting machine, Irregular glass cutting machine |

![]()

Applications:

CKD CC-GDA1 laser glass cutting machine is a perfect choice for customers who need to cut thick glass, colored glass and acrylic. It can work in temperatures 26℃, with ultra fast picesecond speed and 50HZ/60HZ working frequency. It is equipped with HTI control system and 30/50/60/80w laser power to ensure the accurate cutting result.

The principle of infrared picosecond laser cutting glass is that through the interaction of laser and glass, the local thermal effect of high energy density is generated, which causes instantaneous heating and expansion of the glass, thereby causing the fracture of the glass. During the cutting process, the laser beam can be controlled to form a tiny heat source on the glass surface, and accurate cutting lines and shapes can be achieved through appropriate laser parameter adjustment.

Our Laser Glass Cutting Machine is ideal for irregular glass cutting, stained glass cutting and optical glass laser cutting. Have the following advantages

1)High precision: The infrared picosecond laser has extremely high positioning accuracy and cutting accuracy, which can achieve fine cutting and is suitable for cutting glass with complex shapes.

2)High efficiency: infrared picosecond laser pulse width is very short, high energy density, fast cutting speed, can quickly complete the cutting task, improve production efficiency.

3)Smooth no cracks: During the infrared picosecond laser cutting process, a very small heat-affected area can be generated, reducing or eliminating the cracks generated by cutting, so that the surface of the cut glass is smooth and flawless.

4)Wide applicability: infrared picosecond laser cutting can be applied to various types of glass materials, including brittle glass, tempered glass, laminated glass, etc.

![]()

Support and Services:

We provide technical support and services for our Laser Glass Cutting Machine. Our team of specialists is available to help you with any technical issues you may encounter when working with our machine. We provide the following services:

- Installation and setup assistance

- Troubleshooting and repair

- Software and hardware upgrades

- Maintenance and preventive care

- Consultation and advice on usage and operation

- Replacement parts

We are committed to providing excellent customer service and support. If you have any questions or concerns, please do not hesitate to contact us.

Packing and Shipping:

Packaging and Shipping for Laser Glass Cutting Machine:

The laser glass cutting machine will be packaged in sturdy cardboard boxes or wooden crates, depending on the size and weight of the machine. All packing material will be designed to protect the machine and its components from damage during shipping. All components will be securely fastened in the box to prevent damage from movement. The box will be marked with the appropriate shipping labels and tags.

The laser glass cutting machine will be shipped via air or sea, depending on the customer's preference. All necessary shipping documents such as invoices, bills of lading, and customs documents will be provided with the shipment.

![]()

FAQ:

Q&A for Laser Glass Cutting Machine

Q1: What's the brand name of the laser glass cutting machine?

A1: The brand name of the laser glass cutting machine is CKD.

Q2: What's the model number of the machine?

A2: The model number of the machine is CC-GDA1.

Q3: Where is the laser glass cutting machine made?

A3: The laser glass cutting machine is made in China.

Q4: Does the machine have ISO certification?

A4: Yes, the machine has ISO certification.

Q5: What's the minimum order quantity?

A5: The minimum order quantity is 1.