High Frequency Laser Glass Cutting Machine 220V With 0.1-25mm Cutting Thickness

-

Highlight

High Frequency Laser Glass Cutting Machine

,Laser Glass Cutting Machine 220V

,ISO Laser Glass Cutting equipment

-

NameGlass Cutting Equipment

-

Cutting Speed0-500mm/s

-

Cutting Accuracy±0.01mm

-

Working Voltage220V

-

Key Selling PointsUltra Fast Picesecond

-

Control SystemHTI Control

-

Laser Power30/50/60/80w

-

Cooling SystemWater Cooling

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO

-

Model NumberCC-GD10

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden box

-

Delivery Time15-30 days

-

Payment TermsL/C, T/T, L/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability50 sets per month

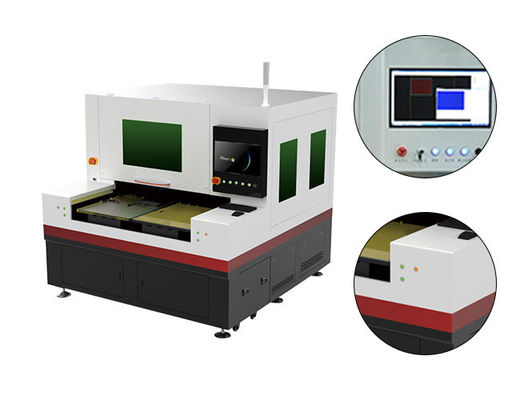

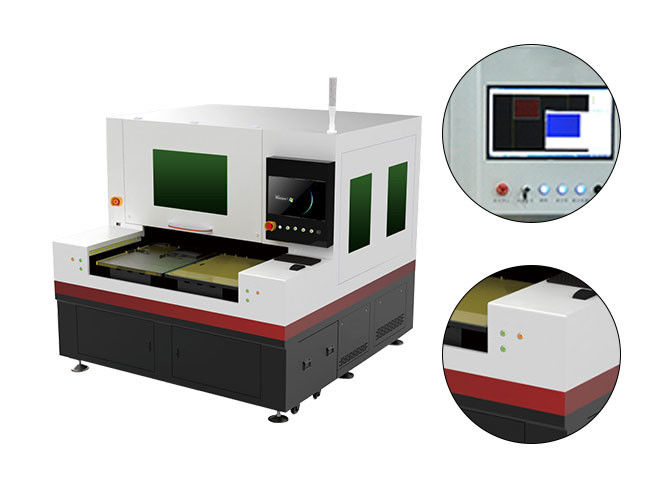

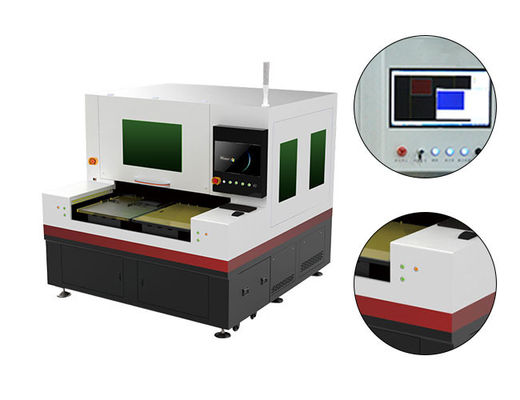

High Frequency Laser Glass Cutting Machine 220V With 0.1-25mm Cutting Thickness

High Frequency Laser Glass Cutting Machine

with 0.1-25mm Cutting Thickness

Product Description:

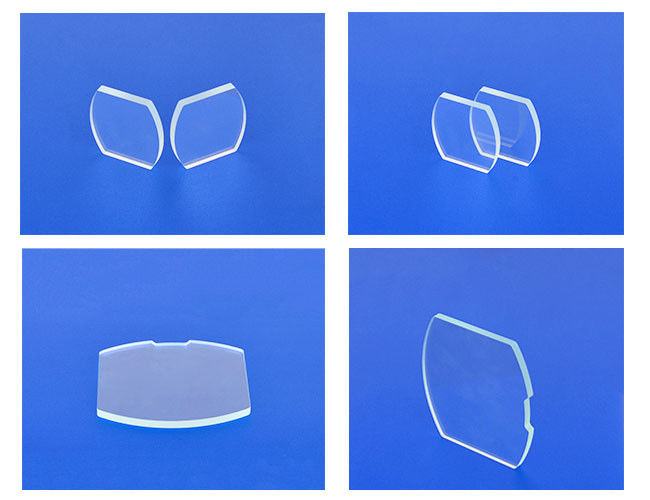

This Laser Glass Cutting Machine is specifically designed for thick glass processing, such as polygonal and irregular shapes. It is equipped with advanced infrared picosecond laser to ensure the cutting accuracy of ±0.01mm, and its adjustable laser power can support the cutting thickness from 0.1mm to 25mm. This machine is also equipped with a water cooling system that can rapidly reduce the temperature of the cutting surface and greatly reduce glass processing time. In addition, its rack and pinion transmission system provides smooth and reliable operation for the machine.

Features:

- Product Name: Laser Glass Cutting Machine

- Control System: HTI Control

- Laser Type: Infrared Picosecond

- Transmission System: Rack And Pinion

- Working Voltage: 220V

- Cutting Area: 400mm*500mm/ 600*700mm/ 600*900mm

- Specialty: Single Table Glass Cutting Machine, optical glass Laser Cutting Machine, colored glass cutting machine

Technical Parameters:

| Parameters | Stained Glass Cutting Machine |

|---|---|

| Material | Glass |

| Laser Power | 30/50/60/80w |

| Transmission System | Rack And Pinion |

| Working Frequency | 50HZ/60HZ |

| Working Environment | 26℃ |

| Cutting Thickness | 0.1-25mm |

| Working Voltage | 220V |

| Laser Type | Infrared Picosecond |

| Cutting Speed | 0-500mm/s |

| Cutting Accuracy | ±0.01mm |

| Parameters | Fiber Laser Cutting Machine |

|---|---|

| Material | Glass |

| Laser Power | 30/50/60/80w |

| Transmission System | Rack And Pinion |

| Working Frequency | 50HZ/60HZ |

| Working Environment | 26℃ |

| Cutting Thickness | 0.1-25mm |

| Working Voltage | 220V |

| Laser Type | Infrared Picosecond |

| Cutting Speed | 0-500mm/s |

| Cutting Accuracy | ±0.01mm |

| Parameters | High Precision Laser Cutting Machine |

|---|---|

| Material | Glass |

| Laser Power | 30/50/60/80w |

| Transmission System | Rack And Pinion |

| Working Frequency | 50HZ/60HZ |

| Working Environment | 26℃ |

| Cutting Thickness | 0.1-25mm |

| Working Voltage | 220V |

| Laser Type | Infrared Picosecond |

| Cutting Speed | 0-500mm/s |

| Cutting Accuracy | ±0.01mm |

Customized process

Support and Services:

We provide technical support and services for our Laser Glass Cutting Machine in order to ensure our customers have the best experience with their machine. We provide a 24/7 customer service hotline, as well as email and online support.

We also provide installation and maintenance services for our customers if needed. Our technicians can install and troubleshoot the machine to ensure that it works properly. We also provide regularly scheduled maintenance to ensure the longevity of the machine.

We also have a team of engineers available to answer any technical questions or provide assistance with any problems that may arise. We are always happy to help our customers get the most out of their machine.

Packing and Shipping:

For safe and secure packaging and shipping of Laser Glass Cutting Machine, we use high-quality and durable packaging materials that protect the machine from any damage during shipping.

The machine is securely placed in a wooden crate or carton, and then wrapped in foam to prevent any kind of shifting during the transit. The machine is also secured with straps for added stability.

The package is then sealed with a plastic wrap to protect it from any weather conditions.

The package is then labeled with all necessary information regarding the machine, such as the manufacturer, model number, and destination address.

The package is then ready for shipping via reliable and safe shipping carriers.

FAQ:

Q1: 1. who are we?

A1:Established in 2010,Shenzhen CKD Precision Mechanical & Electrical Co., Ltd is a laser equipment manufacturer and automation

New Intelligent Manufacturing solution provider, specializing in the R&D, production, sales, and service.

Q2: how can we guarantee quality?

A2: our product technology has achieved innovation and breakthroughs in fields such as ultra-fast laser cutting, laser drilling, TFT-LCD screen laser repair, laser welding, and laser marking. Especially in the automation new intelligent manufacturing of glass brittle material processing and TFT-LCD repair industry, the company provides customers with low-cost, high-quality, and efficient solutions, making contributions to customer value, innovation, and development.

Q3: why should you buy from us not from other suppliers?

A3: Both wholesale and Customize design, development, New technology Real manufacture with own factory Fast reaction and top service Quick delivery High Quality standard Prompt and high quality after sale service