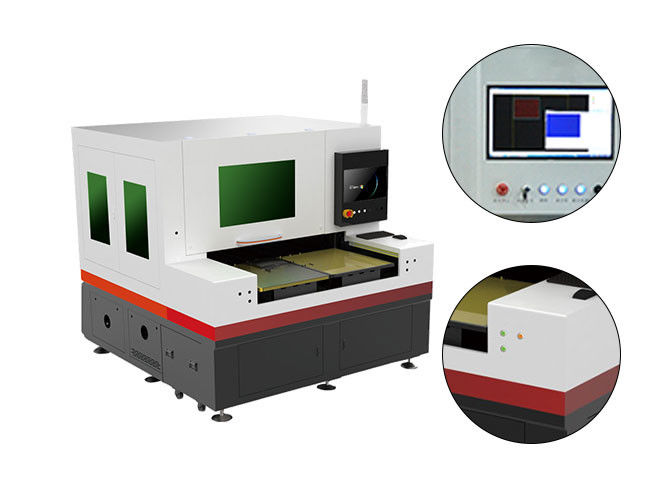

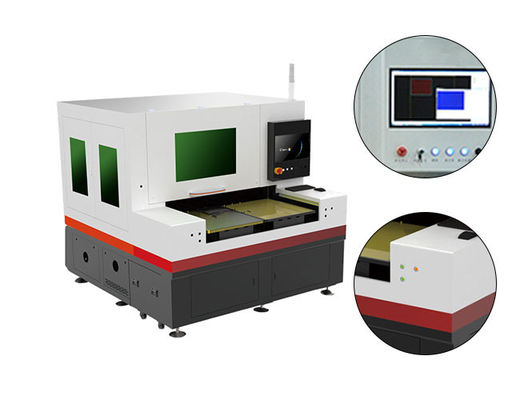

Unibody Raycus Laser Cutting Machine 3 Axis With Rack / Pinion Transmission System

-

Highlight

Unibody Raycus Laser Cutting Machine

,ISO 3 Axis Laser Cutting Machine

-

NameGlass Cutting And Splitting Machine

-

Machinery Efficiency0-500mm/s

-

Accuracy Of Segmentation±0.01mm

-

Glass ThicknessLess Than 25mm

-

Work Size610*700mm X 2

-

Laser Power80W

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO

-

Model NumberCC-GDA1

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-30 Work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

Unibody Raycus Laser Cutting Machine 3 Axis With Rack / Pinion Transmission System

Unibody Laser Glass Cutting Machine With Rack And Pinion Transmission System

The working principle of the laser glass cutting machine is to use a laser beam to cut the glass material. After the laser beam is focused by the optical system, the glass surface is ablated or melted to form a cutting line. By controlling the movement and power of the laser beam, the glass can be cut

The product described

1 . Self-developed glass cutting head, lens all imported, light spot fine, deep focus;

2 . Support cutting segments in one piece

3 . Motion control standard PSO function, uniform control of laser spot spacing;

4 . The device aligns CCD and telecentric vision lens to accurately identify mark points such as circle and cross.

5 . One knife can cut up to 19mm thickness:

6 . Motor platform, optical platform base using natural marble, accuracy is more guaranteed;

Key attributes |

|

|

Laser Type |

Fiber Laser |

|

Cutting Speed |

0-500mm/s |

|

Work Size |

600*700mm*2 |

|

Accuracy |

±0.01mm |

|

Cutting Thickness |

0-25mm |

|

Chipping |

≤5μm |

|

Laser Source Brand |

RAYCUS |

|

Configuration |

3-axis |

|

Graphic Format Supported |

AI, DXF, Dst, DXP |

|

Laser Head Brand |

Raytools |

|

Laser power |

20W/30W/40W/50W60W/70W |

|

Cutting materials |

Glass/tempered glass/screen Protector |

| Guiderail Brand | HIWIN |

![]()

Advantages over traditional cutting

1. Faster cutting speed

Laser glass cutting machine uses high energy laser beam to directly evaporate or melt the glass material, cutting speed is faster, more efficient than traditional water knife cutting .

2 . Higher cutting accuracy

laser glass cutting machine has high positioning accuracy and cutting accuracy, can achieve very small cutting lines and complex shape cutting, while water knife cutting is affected by the impact of water flow and the size of the cutting head, the accuracy is relatively low .

3 . The cutting surface is smoother

the glass surface after cutting by the laser glass cutting machine is smooth, and there is no need for secondary processing, while the water knife cutting will produce water impact during the cutting process, which is easy to cause the cutting surface to be rough, and subsequent polishing and other treatments are required .

4 . Lower cutting cost

laser glass cutting machine does not need to use cutting tools, only need laser energy, saving the cost of cutting tools, while water knife cutting requires the use of high pressure water flow and abrasive, the cost is relatively high .

Applied Range

Picosecond laser glass cutting machine is a kind of equipment specially used for cutting glass materials, with high precision, high efficiency and low thermal impact. The following are some common applications of picosecond laser glass cutting machines

1 . Plate glass cutting

Picosecond laser glass cutting machine can be used for plate glass cutting, such as architectural glass, furniture glass, window glass and so on.

2 . Glassware cutting

Picosecond laser glass cutting machine can be used for cutting glassware, such as glasses, glass bowls, glass bottles, etc.

3 . Glass tube cutting

Picosecond laser glass cutting machine can be used for cutting glass tubes, such as glass test tubes, glass pipes, etc.

4 . Fiber cutting

Picosecond laser glass cutting machine can be used for cutting optical fibers, such as fiber connectors, fiber pigtails, etc.

5 . Optical device cutting

picosecond laser glass cutting machine can be used for cutting optical devices, such as optical lenses, optical prisms, etc.

6 . Electronic device cutting

Picosecond laser glass cutting machine can be used for cutting electronic devices, such as electronic display screens, touch screens, etc.

![]()

After-sales Services

1 . 1 year guarantee for fiber laser cutting machine .

2 . Full technical support by e-mail, call and video

3 . Lifelong maintenance and spare parts supply.

4 . Free design of fixtures as customers required.

5 . Free training installation and operation for the staffs.