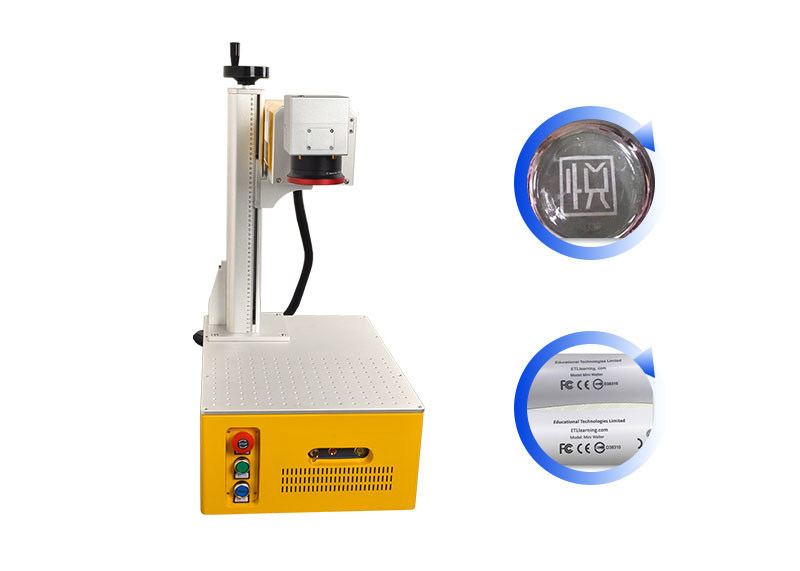

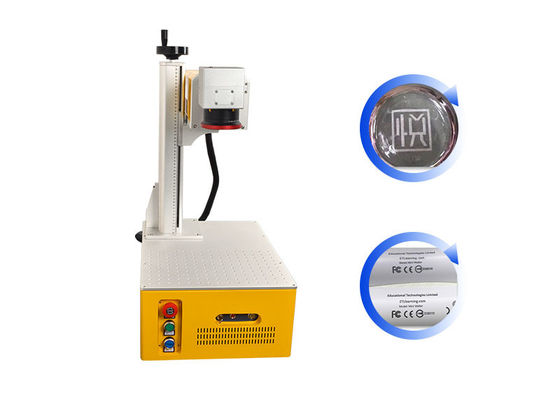

ABS / Plastic UV Laser Marking Machine 10W 175*175mm Working area

-

Highlight

UV Laser Marking Machine 10W

,Plastic UV Laser Marking Machine

,10W Laser Marking Machine Plastic

-

NamePlastic UV Laser Marking Machine

-

Laser TypeUV Laser

-

Laser Power10W

-

Laser Source BrandMAX

-

Mode Of OperationPulsed

-

Marking Area175mm*175mm

-

Graphic Format SupportedAI / PLT / DXF / BMP / Dst

-

Place of OriginSHENZHEN, CHINA

-

Brand NameCKD

-

CertificationCE

-

Model NumberCM-U1

-

Minimum Order Quantity1

-

PriceUSD1300 - USD 2500 / Set

-

Packaging DetailsWooden Box

-

Delivery Time10-15 work days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability1000 Set/Sets Per Month

ABS / Plastic UV Laser Marking Machine 10W 175*175mm Working area

Personal Mini Portable UV Laser Marking Machine Yellow Color Marking ABS And Placstic

PRODUCT PARAMETER

| Laser Type | UV |

| Laser Power | 10W |

| Cooling Mode | Air Cooling |

| Graphic Format Supported | AI / PLT / DXF / BMP |

| Working Accuracy | 0.1mm |

| Weight (KG) | 55 KG |

| Control Software | EZCAD |

| Laser source | MAX |

| Working area | 175*175mm |

| Software | EZCAD2 |

| Marking Depth | 0.01- 2 mm |

| Marking material | Glass / Aluminium / ABS / EVA |

INTRODUCTION OF THE MACHINE

UV Laser Marking Machine is a marking device that uses 355nm ultraviolet laser to hit a laser beam on the surface of various substances, and directly breaks the molecular chain of substances through a short-wavelength laser to reveal permanent marks such as patterns, trademarks, and words.

Ultraviolet laser is a very different technology from carbon dioxide and fiber laser technology, ultraviolet laser is also known as blue laser beam, the technology has a low calorific engraving ability. The light wave or ultraviolet spectrum of the UV laser marking machine is one of the main reasons why this technology can be engraved on different materials, because it does not heat the surface of the material like the optical fiber and carbon dioxide laser marking machine, which is cold light engraving.

Uv laser marking machine has a wide range of applications, can clearly mark all the plastic and other materials that have adverse reactions to heat, especially suitable for food, pharmaceutical packaging materials marking, punching microholes, high-speed division of glass materials and silicon wafers for complex graphics cutting and other applications, metal, wood, glass and almost all plastic types can be carved with UV laser technology.

Uv laser marking machine is mainly used for ultra-fine marking and engraving, especially suitable for the high-end market of ultra-fine processing, the marking effect is fine, the mark is clear and firm, better than the general ink inkjet and pollution-free. Suitable for flexible pcb board marking, marking; Silicon wafer microhole, blind hole processing; LCD glass two-dimensional code marking, glass utensil surface punching, metal surface coating marking; Plastic buttons, electronic components, gifts, communication equipment, building materials and other materials marking.

HOW TO USE THE MACHINE

A boot steps:

① Check that the ground cable of the device is grounded.

② Check whether the power cord of the laser marking machine is correctly connected and reliable.

③ Insert the key switch, turn 90o clockwise to the "on" position, turn on the main power supply, and the power indicator is on.

④ Confirm that the laser marking machine emergency stop switch is pressed.

⑤ Turn on the power switch of the computer host and computer monitor.

⑥ Rotate the red emergency stop switch in the direction of the arrow, so that it springs up, you can turn on the laser head power supply, about 1 minute after the laser head is started.

⑦ Remove the lens cap; At this point, the laser marking machine is opened and can accept the operator's command for marking operation.

Two dozen mark operation

① Double-click the marking program icon to enter the program.

② Select the marking file, double-click the date and time in the content to modify, click OK, the modification is complete.

Three dozen mark test and print position

① On the workbench or production line, place a test piece equal to the height of the marking workpiece, and confirm that the test piece is indeed stable.

② Mark by operating the marking control software. To make the marking effect the most. Preferably, the following steps can be adjusted.

Fourth, adjust the focal length by adjusting the head lifting device.

① Adjust power, marking speed and other parameters in the marking software.

② Enter the software, double-click the print date, and drag it up and down with the mouse to adjust the print position to the appropriate position.

③ Print test can be carried out after completing the above steps.

④ After the test is correct, re-mark the workpiece.

five-off

① Press the red mushroom button (emergency stop switch) to cut off the laser head power supply.

② After confirming that the industrial computer does not run any software, exit and shut down normally.

③ Turn the key switch 90o counterclockwise to the "off" position, turn off the main power supply of the marking machine, and the power indicator is off.

④ Unplug the key and keep it for the next use.

⑤ Close the lens cap.

WHAT CAN THE MACHINE MARKING

![]()

APPLICABLE INDUSTRY

Uv laser marking machine with its unique low-power laser beam, especially suitable for the high-end market of ultra-fine processing, cosmetics, drugs, food and other polymer materials packaging bottle surface marking, fine effect, clear and firm marking, better than ink coding and pollution-free; Flexible pcb board marking, scribing; Silicon wafer microhole, blind hole processing; LCD glass two-dimensional code marking, glassware surface punching, metal surface coating marking, plastic keys, electronic components, gifts, communication equipment, building materials and so on.

PACKAGE AND SHIPMENT

1.We have three layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickening plastic bag for waterproof.

2.Air-worthy packing or Sea packing which with international standard.

![]()

SERVICE

1.one year quality guaranty, the machine with main parts shall be changed free of charge when if any problem during the warranty period.

2. Lifetime maintenance free of charge.

3. Free training course at our plant.

4.Machine has been adjusted before delivery.

5.For free sample testing, please send us your file, we will do marking here and make video to show you the effect, or send sample to you for checking quality.

FAQ

Q1. What support do I get with my laser machine?