-

Highlight

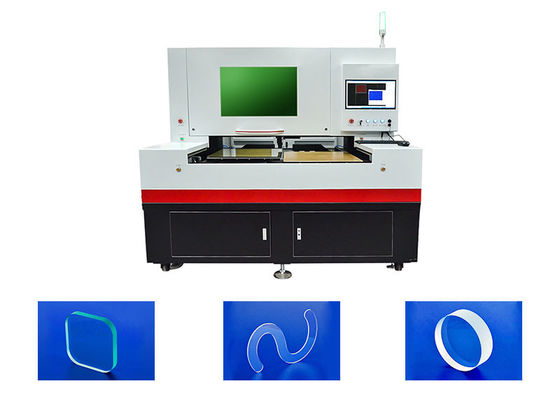

1064nm Laser Glass Cutting Machine

,Laser Glass Cutting Machine 600mm*800mm

,Glass Laser Cutting Machine 80W

-

NameInfrared Picosecond Cutting

-

Cutting Area600*800mm

-

Accuracy±0.01mm

-

ThicknessLess Than 25mm

-

Speed0-500mm/s

-

Chipping≤5μm

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO

-

Model NumberCC-GDA6

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-30 Work days

-

Payment TermsL/C, D/A, D/P

-

Supply Ability50 Sets Per Month

1064nm Laser Glass Cutting Machine

80W Infrared Picosecond Glass Laser Cutting Machine

1064nm Wavelength CCD Positioning Compensation

General description of equipment

1, glass cutting equipment mechanism is composed of laser, XY1Y2Z axis, CCD, standard optical path, precision

cutting software control system, water cooler, vacuum adsorption, composition; note that the equipment and water

cooler for the standard 220V voltage.

2, the equipment use environment clean workshop indoor temperature 20-25 ℃, beyond 26 ℃ use will have an

impact on the life of the laser.

3, the water cooler needs to be used in accordance with the requirements of the cooling water (distilled water /

pure water) once a month to replace the water.

| Technical parameters | |

| X/Y movement speed: | max. 500mm/s |

| Laser type | Infrared picosecond |

| Laser wavelength | 1064nm |

| Laser class | Class4 |

| Laser power | 10W/20W/40W/70W optional |

| Pulse length | ≤10PS |

| pulse frequency | 1Hz-1000kHz |

| Working mode | laser XY moving |

| Cooling method | water-cooled |

| Focusing mode | cutting head |

| Focusing spot | ≤Ф3um |

| Cutting speed | adjustable 0-500mm / s |

| Cutting thickness | according to the thickness of the glass to choose the number of laser W |

| Minimum cutting edge chipping | 6um |

| X / Y cutting stroke | 400mm x500mm (600X700mm 600X900 optional or customize a larger platform) |

| X/Y positioning accuracy | ≤±2μm |

| X/Y repeat positioning accuracy | ≤±1um |

![]()

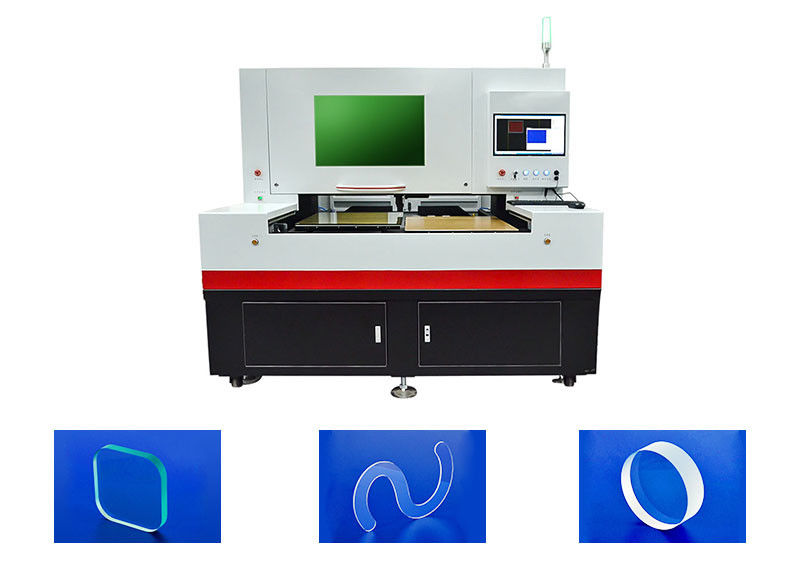

Machine Application

Adopted Picosecond IR Ultra-fast Lasers are robust and affordable, it produces high energy pulses with durations below 10 ps. The laser is based on a hybrid optical amplier architecture that combines the advantages of fiber laser technology with solid state diode pumped multi-pass ampliers. Compact and water-cooled, this laser is low maintenance and never needs realignment. With burst mode optional, it could be suitable for variety applications with low cost.

Product Overview

Pre-sales services

*Inquiring and consulting support;

*Sample testing support;

*Visiting our factory;

After-sales services

*Engineers available to service machinery overseas;

*Training how to install and use the machine;

*Free parts;

![]()

Packing

Depends on different situation (weight, volume, country...), the shipping method could be different and its negotiable.

Samples

1 . 0.1mm-6mm reinforced and non-reinforced glass cutting, such as mobile phone glass cover, car glass cover, camera glass cover etc.

2 . 0.1mm-2mm Sapphire glass cutting , such as mobile phone sapphire cover , camera sapphire glass cover , sapphire light bar (LED light bar) etc .

3 . LCD screen glass cutting , such as special-shaped LCD screen inverted R / U / C angle , LCD screen cutting .

4 . Other optical lens cutting , such as filter cutting , mirror cutting etc .

![]()

FAQ

Q: What’s the package?

A: We have 3 layers package: The outside is plywood case, which is fumigation-free packaging. In the middle is covered with thick sponge to protect the machine from shaking. Inside this is covered by thickening plastic bag for waterproof.

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation.

Q: How to install and run the machine?

A: Our engineer have installed and tested the machine before shipping. No parts need installed.

we have menus and videos to show you for training. And we also will training you on line. Most of customers

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us ASAP and do not try to fix the machine by yourself or someone else. We will response within 24 hours as quickly as we can to solve it for you.