60*80cm Automatic Glass Laser Cutting Machine For Tempered Glass

-

Highlight

ISO Laser Cutting Tempered Glass Machine

,60*80cm Automatic Glass Laser Cutting Machine

,Automatic Laser Cutting Machine For Tempered Glass

-

NameAutomatic Glass Cutting Machine

-

Laser TypeFiber Laser

-

Cutting Speed0-500mm/s

-

Cutting Area60*80cm

-

Laser Source BrandRAYCUS

-

Configuration3-axis

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO

-

Model NumberCC-GCS2

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-30 Work days

-

Payment TermsL/C, D/A, D/P

-

Supply Ability50 Sets Per Month

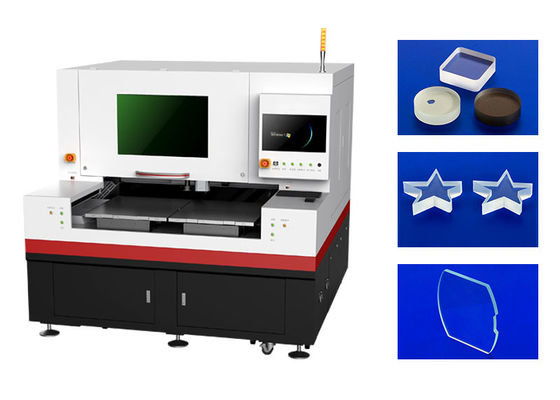

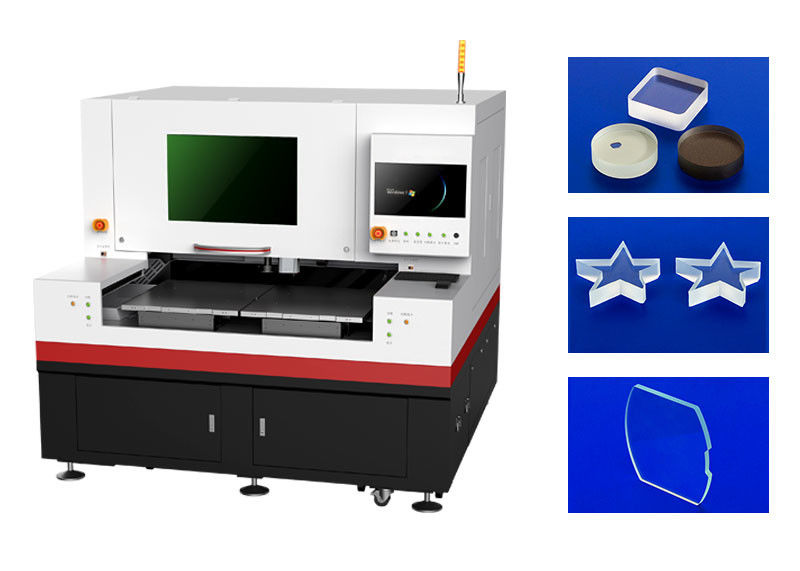

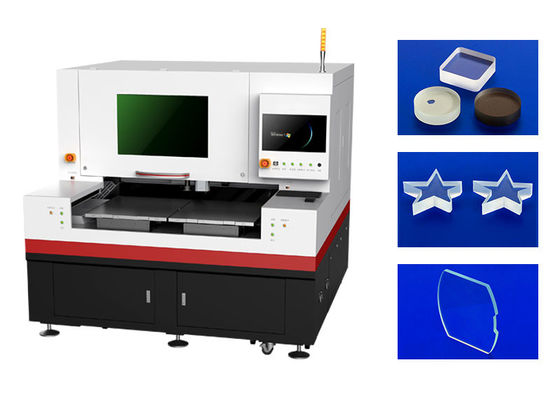

60*80cm Automatic Glass Laser Cutting Machine For Tempered Glass

Infrared Picosecond Glass Screen Protector Glass Cutting Machine

Product Description

1 . High precision

2 . fast speed

3 . good stability

4 . long life

Excellent in cutting glass for mirrors, light fittings, ovens, gas stoves, trophies, crafts, mobile phones, doors and windows. Can be applied to different thickness of glass round, square, polygon, irregular shaped laser cutting.

| significant attribute | |

| X/Y movement speed | max. 500mm/s |

| Laser type | Infrared picosecond |

| Laser wavelength | 1064nm |

| Laser power | 10W/20W/40W/70W/80W optional |

| Pulse length | ≤10PS |

| Pulse frequency | 1Hz-1000kHz |

| Working mode | Laser XY moving |

| Cooling method | Water-cooled |

| Focusing mode | Cutting head |

| Focusing spot | ≤Ф3um |

| Cutting speed | Adjustable 0-500mm / s |

| Cutting thickness | according to the thickness of the glass to choose the number of laser W |

| Minimum cutting edge chipping | 6um |

| X / Y cutting stroke | 400mm x500mm (600X700mm 600X900 optional or customize a larger platform) |

| X/Y positioning accuracy | ≤±2μm |

| X/Y repeat positioning accuracy | ≤±1um |

![]()

Applying Materials

1. Brittle materials/strengthened and non-strengthened glass cutting:

1. Brittle materials/strengthened and non-strengthened glass cutting:

3. optical or Other glass cutting:

Sample Display

1. Shape:

2. Thickness:

![]()

SUBSEOUENT SPLIT PROCESSING

1. Non-strengthened glass: CO2 laser can be used to heat along the cutting line, sothat the glass will be heated to produce stress and separate the shards / after cutting,it will be strengthened twice to produce stress shards;

2. Tempered glass: After cutting, the self-strengthening stress is released and thesplinters are separated automatically;

3. LCD screen glass: mechanical pulling, firing pin split / ultrasonic split;4. Filter glass: mechanical knife lobes, etc.;5. Camera protection glass: laser cracking or soaking in chemical medicine, etc.

Whether the equipment needs a CO2 laser splitter, please contact ourcustomer service to confirm!

WHY CHOOSE US