Grating Ruler Laser Glass Cutting Machine For Optical Filters Precision Cutting

-

Highlight

Grating Ruler Laser Glass Cutting Machine

,Optical Filters Laser Glass Cutting Machine

,Precision Cutting Laser Glass Cutting Machine

-

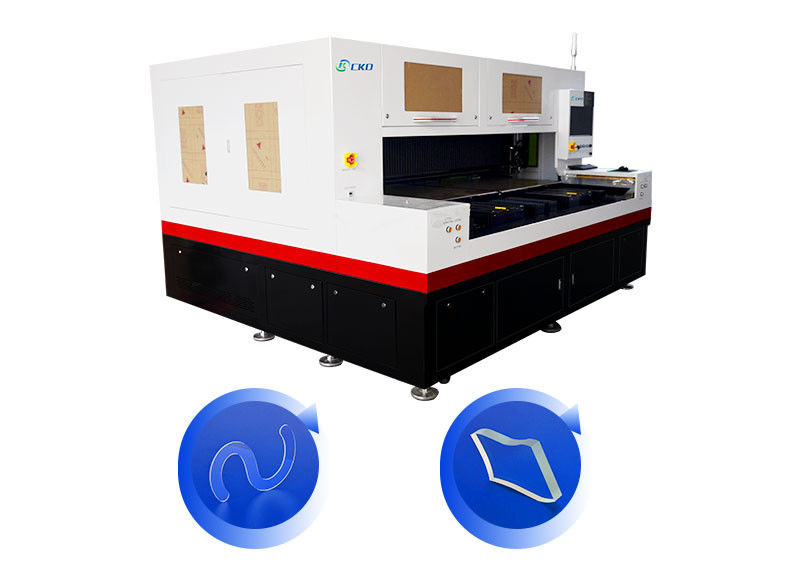

NameGlass Cutting And Splitting Machine (All-in-One)

-

Laser Wavelength1064nm

-

Working Frequency50HZ/60HZ

-

MaterialOptical Filters

-

Working Environment26℃

-

Transmission SystemRack And Pinion

-

Cooling SystemWater Cooling

-

Key Selling PointsUltra Fast Picesecond

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO / CE / FDI

-

Model NumberCC-GDA19

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden box

-

Delivery Time15-45 days

-

Payment TermsL/C, T/T

-

Supply Ability50 sets per month

Grating Ruler Laser Glass Cutting Machine For Optical Filters Precision Cutting

Grating Ruler Laser Glass Cutting Machine

For Optical Filters Precision Cutting

Product Description:

Optical glass is a typical brittle material, making it especially difficult to obtain high-quality surfaces by conventional CNC machining. However, with the introduction of non-contact laser technology, machining optical glass to the required cutting precision and quality is now achievable. This can be realized by integrating features such as a picosecond infraredultra-fast laser source, high-precision moving components, a fully automated asynchronous intelligent loading and unloading structure, and a CCD camera for automatic positioning and monitoring.

Features:

This equipment is mainly used for cutting glasses of all kinds . It can be used for smart home displays cutting , such as camera lens laser cutting, coated lens cutting , heterosexual glass laser cutting , LCD screen laser cutting, automobile central control glass cutting , mobile phone glass cover cutting , photovoltaic glass cutting and glass cutting and drilling . Moreover , it has wide applications in high-precision marking and cutting of glass , drilling and cutting of sapphire , marking / drilling / cutting of ceramics , cutting of LCD/OLED display panels , LED wafer dicing and cutting , etc .

The laser equipment has the feature of automatically locating and cutting by vision , which makes it outstanding in the aspect of speed and positioning accuracy . It is also worth mentioning that when it is in the process of movement , there is no contact between the stator and the mover, thus no wear and tear is caused for a long time. Additionally , it does not require much maintenance and handling .

Technical Parameters:

| Product Property | Parameter |

|---|---|

| Working Frequency | 50HZ/60HZ |

| Working Environment | 26℃ |

| Working Voltage | 220V |

| Laser Wavelength | 1064nm |

| Cooling System | Water Cooling |

| Cutting Area | 400mm*500mm/ 600*700mm/ 600*900mm |

| Laser Type | Infrared Picosecond |

| Cutting Accuracy | ±0.01mm |

| Cutting Speed | 0-500mm/s |

| Material | Optical Lenses / Optical Mirrors / Windows and Diffusers / Optical Filters / Polarization Optics / Beamsplitters / Prisms / Diffraction Gratings |

| Special Feature | Polygonal glass cutting machine , Fiber Laser Cutting Machine , Single Table Glass Cutting Machine |

![]()

Applications:

Laser source: High energy infrared picosecond lasers are used to produce high energy laser beam.

Optical mirror system: This system consists of lens, mirrors and other optical components. It is used to focus and guide the laser beams, achieving high precision cuts.

Control system: State-of-the-art numerical control technology is adopted to achieve precision control of laser cutting machine, including motion control and laser power control.

Table: The table serves as a platform for placing and fixing glass materials. Usually, it comes with automatic feed and discharge systems to boost production efficiency.

Cooling system: This system helps cool lasers and optical components, so as to maintain the operating temperature in a stable mode.

Safety protection system: A series of safety equipments, such as gratings, warning lights, an emergency stop button, are put in place to better protect the operators.

By combining these configurations, the optical mirror glass laser cutting machine can execute high-precision and high-efficiency cutting processings on glass materials.

Customization:

Brand Name : CKD

Model Number : CC-GDA17

Place of Origin : China

Certification : ISO

Minimum Order Quantity : 1

Price : Negotiated

Packaging Details : Wooden box

Delivery Time : 15-45 days

Payment Terms : L/C, T/T

Supply Ability : 50 sets per month

Control System : HTI Control

Working Voltage : 220V

Material : Glass

Laser Power : 30/50/60/75/80/90w

Laser wavelength : 1064nm

Our Laser Glass Cutting Machine is perfect for single table glass cutting and irregular glass cutting. It is a polygonal glass cutting machine with precise cutting results. Our machine is powered by HTI Control and has a working voltage of 220V. It is certified by ISO and is equipped with a laser power of 30/50/60/75/80/90w and a laser wavelength of 1064nm . It comes with a wooden box packaging and a minimum order quantity of 1 .

Support and Services:

Laser Glass Cutting Machine technical support and services include :

- Regular maintenance of hardware and software

- Assistance with setup and installation

- Troubleshooting and repair of hardware and software

- Software updates and upgrades

- Technical support via phone , email , or in-person visits

- On-site support for service and maintenance

- Training and education for users

Packing and Shipping:

Packaging and Shipping of Laser Glass Cutting Machine :

- The laser glass cutting machine will be carefully packed with a thick layer of bubble wrap for extra protection .

- The package will be placed into a cardboard box and sealed with tape .

- The package will be shipped via a reliable shipping company .

FAQ:

- Q : What is the Brand Name of this Laser Glass Cutting Machine ?

- A : The Brand Name of this Laser Glass Cutting Machine is CKD .

- Q : What is the Model Number of this Laser Glass Cutting Machine ?

- A : The Model Number of this Laser Glass Cutting Machine is CC-GDA17 .

- Q : Where is this Laser Glass Cutting Machine made ?

- A : This Laser Glass Cutting Machine is made in China .

- Q : Is this Laser Glass Cutting Machine certified ?

- A : Yes, this Laser Glass Cutting Machine is ISO certified .

- Q : What is the minimum order quantity ?

- A : The minimum order quantity is 1 .