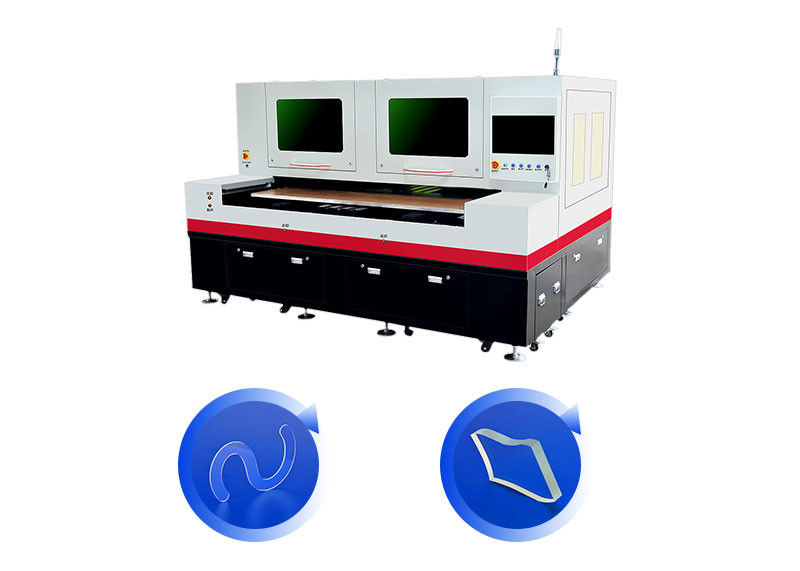

Infrared Picosecond Laser Glass Cutting Machine For Windows And Diffusers

-

Highlight

Windows Laser Glass Cutting Machine

,Diffusers Laser Glass Cutting Machine

-

NameGlass Cutting And Splitting Machine (All-in-One)

-

Cutting Speed0-500mm/s

-

Cutting Accuracy±0.01mm

-

Working Voltage220V

-

Working Frequency50HZ/60HZ

-

MaterialWindows And Diffusers

-

Drive MotorXY Linear Motor + Grating Ruler

-

Cooling SystemWater Cooling

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO / CE / FDI

-

Model NumberCC-GDA18

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden box

-

Delivery Time15-45 days

-

Payment TermsL/C, T/T

-

Supply Ability50 sets per month

Infrared Picosecond Laser Glass Cutting Machine For Windows And Diffusers

Infrared Picosecond Laser Glass Cutting Machine

For Windows And Diffusers

Product Description:

Usually, due to the inherent brittleness of optical glass, traditional CNC machining is not an effective way to achieve high-quality surface.

Fortunately, the revolution of non-contact laser technology has solved the problem. With the combination of picosecond infrared ultra-fast laser source, high-precision moving components, fully automated asynchronous intelligent loading and unloading structure, and CCD camera automatic positioning alignment system, the optical glasses can perfectly meet the requirement of cutting precision and quality.

Features:

This equipment is used for a variety of applications in glass cutting, such as smart home display cutting, camera lens laser cutting, coating lens cutting, straight glass laser cutting, LCD screen laser cutting, automobile central control glass cutting, mobile phone glass cover cutting, photovoltaic glass cutting, glass cutting, and drilling and so on. It can be widely used in glass precise marking and cutting, sapphire drill and cut, ceramic marking, drilling, cutting, LCD, OLED display panel cutting, LED wafer dicing, and cutting and other precision operative fields.

The laser equipment automatically locates and cuts by a vision system, with a high speed and precise positioning accuracy. The stator and the mover will not be in contact with each other when operating, hence there will be minimal wear and tear or even no maintenance is required for a long time.

Technical Parameters:

| Parameters | Value |

|---|---|

| Drive motor | XY Linear Motor + Grating Ruler |

| Working Voltage | 220V |

| Cooling System | Water Cooling |

| Dimension | 2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm |

| Cutting Accuracy | ±0.01mm |

| Weight | 3500kg |

| Laser wavelength | 1064nm |

| Control System | HTI Control |

| Name | Glass Cutting And Splitting Machine (All-in-One) |

| Cutting Speed | 0-500mm/s |

| Keywords | Environmental protection glass laser cutting machine, optical glass Laser Cutting Machine, Small glass laser cutting machine |

![]()

Applications:

Laser source: High energy laser, infrared picosecond laser, used to produce high energy laser beam.

Optical mirror system: including lens, mirror and other optical components, used to focus and guide the laser beam to achieve high precision cutting.

Control system: The use of advanced numerical control technology to achieve precision control of laser cutting machine, including motion control, laser power control.

Table: Used to place and fix glass materials, usually with automatic feed and discharge systems to improve production efficiency.

Cooling system: used to cool lasers and optical components to maintain a stable operating temperature.

Safety protection system: including grating, warning light, emergency stop button and other safety equipment to ensure the safety of operators.

These configurations are combined to form an optical mirror glass laser cutting machine, which can achieve high-precision and high-efficiency cutting processing of glass materials.

Support and Services:

We understand that buying a Laser Glass Cutting Machine is an important investment and our technical support and service is here to ensure you get the most out of your machine. Our team of experts provide a variety of services to help you maximize the performance of your Laser Glass Cutting Machine.

We offer a variety of services to ensure your Laser Glass Cutting Machine remains up and running at its best. Our technical support team is available to answer any questions you have, provide troubleshooting advice, and provide software and firmware updates.

Our team of certified technicians can provide maintenance and repair services for your Laser Glass Cutting Machine. We offer preventive maintenance to ensure the machine continues to run optimally and perform repairs when necessary.

We offer training services to help you get the most out of your Laser Glass Cutting Machine. Our training classes provide hands-on instruction and cover topics such as machine setup, operation, and maintenance.

Packing and Shipping:

Packaging and Shipping for Laser Glass Cutting Machine:

- The product comes with the following components: Laser cutting head, cooling system, cutting table, power supply, and main control unit

- Each component is packed in separate boxes for shipping

- The boxes are made of corrugated cardboard, and are designed to protect the components during shipping

- The boxes are labeled with the product name and part number for easy identification

- The boxes are shipped via standard shipping services, and delivery time depends on the chosen shipping option

FAQ:

- Q: What is the Brand Name of the Laser Glass Cutting Machine?

A: The Brand Name of the Laser Glass Cutting Machine is CKD. - Q: What is the Model Number of the Laser Glass Cutting Machine?

A: The Model Number of the Laser Glass Cutting Machine is CC-GDA17. - Q: Where is the Laser Glass Cutting Machine from?

A: The Laser Glass Cutting Machine is from China. - Q: What is the Certification of the Laser Glass Cutting Machine?

A: The Certification of the Laser Glass Cutting Machine is ISO. - Q: What is the Minimum Order Quantity of the Laser Glass Cutting Machine?

A: The Minimum Order Quantity of the Laser Glass Cutting Machine is 1.