6060 MINI Small Fiber Cutting Machine 1500W For Gold And Silver Cutter

-

Highlight

6060 MINI Small Fiber Cutting Machine

,1500W Small Fiber Cutting Machine

,6060 MINI Fiber Cutting Machine

-

NameSmall Fiber Cutting Machine

-

Cutting Area600mm*600mm

-

Laser Source BrandMAX

-

Laser TypeFiber Laser

-

Fiber Laser1-2000mm/s

-

Cooling ModeWATER COOLING

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO / CE / FDI

-

Model NumberCC-GM3-2

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-45 days

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability50 Sets Per Month

6060 MINI Small Fiber Cutting Machine 1500W For Gold And Silver Cutter

6060 MINI Small Fiber Cutting Machine 1500W

For Gold And Silver Cutter

6060 is a high-precision optical fiber cutting machine , which can cut samples with higher accuracy requirements . The high configuration determines the stability of the machine's operation . In addition , we also have a 600*600/600*400 working format to choose from . This machine is very suitable for small precision processing factories .

Machine Feature

♦ High-rigidity heavy chassis, reducing the vibration generated during high-speed cutting greatly.

♦ Gantry double-drive structure, with imported German rack & pinion transmission system, improves the production efficiency.

♦ High-performance cast aluminum guide rail, after finite element analysis, realizes highly accelerated speed circular arc cutting.

♦ Close-loop laser cutting control system, auto focus, high-speed piercing and automatic tracing-edge function.

Machine Parameters

| Maximum working area | 1500*3000mm,4000*1500mm, 4000*2000mm,6000*2000mm,2500*6000mm ( optional) |

| Cutting thickness | Depend on the laser power |

| Laser power | 1000-20000w |

| Transmission mode | Imported square rail and helical gear |

| Positioning accuracy of X/Y axis | ±0.01 mm |

| Repositioning accuracy of X/Y axis | ±0.02 mm |

| Maximum moving speed of X/Y axis | 120m/min |

| Minimum cutting line width | 0.02mm |

| Floor dimension | Depend on the laser power |

| Whole weight | Depend on the laser power |

![]()

Machinery Details

1 . High cutting speed : The speed of the small CNC laser cutting machine is 2-3 times faster than YAG or Co2 laser.

2 . High cutting accuracy: The laser beam of the small CNC laser cutting machine is up to 0.01mm.

3 . Low maintenance : This kind of small fiber laser cutting machine is almost totally free of maintenance .

4 . The small fiber laser cutting machine adopted German technology ensures high tech in the world .

5 . Optical system : To ensure great laser beam quality can strongly improve the laser power and laser beam quality .

6 . With dynamic auto-focus system: To keep the same distance between the metal sheet and laser head to realize the accuracy of the cutting effect .

7 . With pre-run function : To simulate the laser cutting path, Pre-run the cutting path to ensure the accurate cutting position for the small fiber laser cutting machine .

8 . With red light pointer : As the laser beam is invisible, we adopt red light pointer to indicate the real position of the laser beam to ensure cutting accuracy .

9 . With mirrors and lens cooling technology: All mirrors and lens are cooled by water . Takes the mirror heat during working . Prolong small fiber laser cutting machine lifetime and save future operation costs .

10 . With auto oil-filling system .

![]()

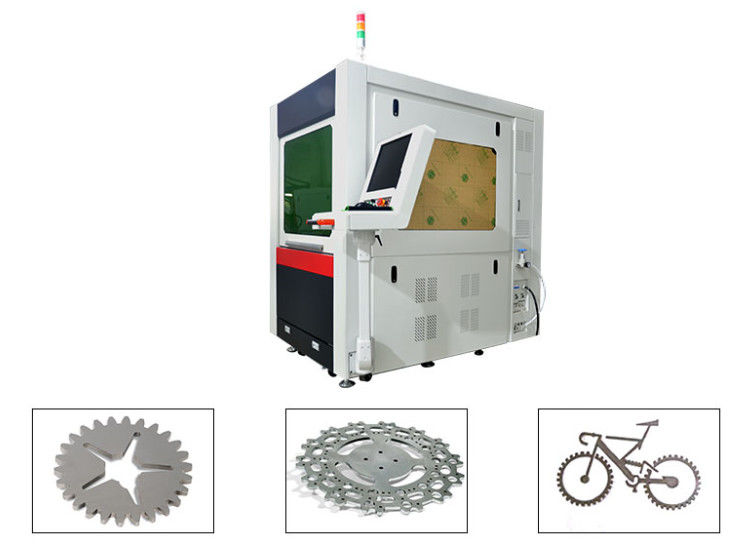

Cutting Samples

Applied materials: This small fiber laser cutting machine is widely applied in carbon steel cutting, mild steel, stainless steel,silicon steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials.

Applied Industry: This small fiber laser cutting machine is widely applied in sheet metal processing, aviation, spaceflight,electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment,elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Cutting Material

Cutting a wide variety of metal plates, tubes, mainly applicable to stainless steel, carbon steel, manganese steel, galvanized sheet, a variety of alloy plates, rare metal and other materials cutting.

Application

Industry of kitchen ware, lamps and lanterns, panel beating, metal cabinets, auto parts, refrigerators, air condition, elevators, hotel metal supplies processing, etc

![]()

FAQ

Q1 : Could I visit your factory ?

A1 : Yes, We will warmly welcome you anytime. It's tooks about 1 hours from

bao'an International airport to our factory.

Q2 : How many years do you do this business?

A2 : From 2008.

Q3 : Does your factory have the design & development capacities, we need customized products?

A3 : yes. The staffs in our design department are well experienced in laser machine, with more than 5 to 10 years experience.

We can make customized products especially for you; Please kindly contact us for more details.

Q4 : What is payment terms?

A4 : 100% T/T advanced.

Q5 : About shiping?

A5 : 3-10 days after payment for standard products, please consult our sales for customized products.

Q6 : How about your after service?

A6 : Our engineers who has long time professional experience and sales will help you within 24h.

Q7 : Do you have patents or core technology?

A7 : Yes, for details, please contact our sales.

Q8 : Where have you sold your products?

A8 : Europe, Americas, Africa, and Asia.