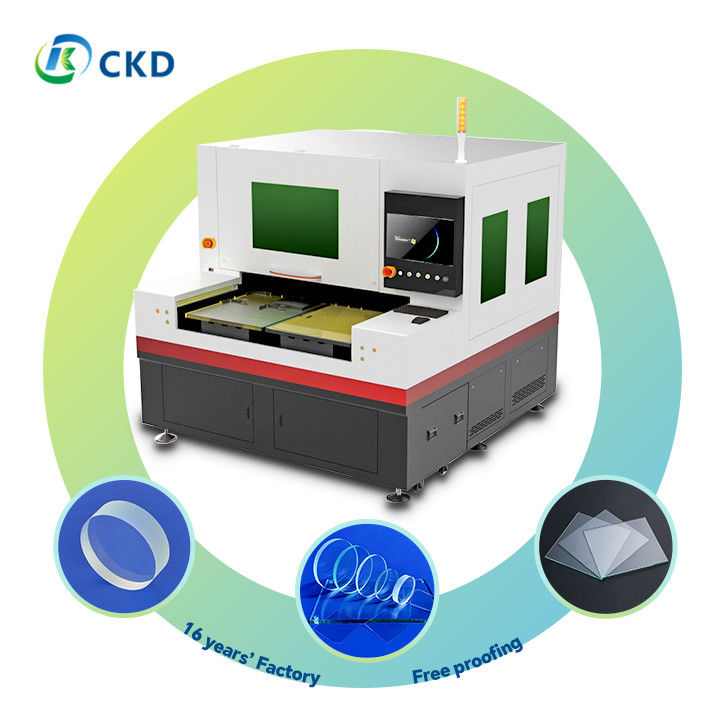

Small Glass Laser Cutting Machine with Heavy Duty Wheels 400x500mm/600x700mm/600x900mm

-

Highlight

400x500mm Glass Laser Cutting Machine

,600x900mm Glass Laser Cutting Machine

-

MobilityEquipped With Heavy-duty Wheels For Easy Movement And Repositioning, With Locking Mechanisms For Stability

-

Cutting ThicknessUltra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm

-

Customizable OptionsCustom Options Available For Table Size, Laser Power (up To 500W), And Special Cutting Heads (like For Curved Or Micro-level Cutting) To Meet Specific Needs.

-

Cutting Area400mm*500mm/ 600*700mm/ 600*900mm

-

Whether CNCYes

-

Impulse Frequency1-100khz

-

Support Image And Text FormatsAI PLT DXF BMP Dst DWg LAS DXP

-

AdvantagesIrregular-shape High-speed Cutting High Cutting Quality, No Taper, No Burr, Small Chipping High Yield Rate, Low Consumables And Energy-saving No Pollution, No Powder, And No Wastewater

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Small Glass Laser Cutting Machine with Heavy Duty Wheels 400x500mm/600x700mm/600x900mm

Product Description:

- High-Power Laser Source: Equipped with a cutting-edge, high-frequency pulsed laser for superior cutting performance.

- Versatile Material Handling: Capable of processing a wide range of materials including metals and non-metals.

- Multifunctional Cutting Capabilities:

- Supports continuous sheet cutting

- Precision single-point cutting

- Efficient strip cutting

- Advanced X/Y Axis Control: Utilizes high-precision DC servo motors and ultra-fine 0.1μm optical encoders for unparalleled accuracy.

- Intelligent Motion Control: Features automatic focus-following functionality and dynamic piercing control.

- High-Resolution Imaging: Incorporates a premium CCD camera system for real-time visual monitoring, pattern recognition, and mark point detection.

- Robust Power Supply: Equipped with a German-made, high-stability power source. Taiwanese brand power supply used for optical components.

- Impressive Cutting Range: Capable of processing materials up to 19mm in thickness, catering to a wide array of industrial applications.

- Precision-Engineered Components:

- Motor base and optical platform constructed with natural granite

- Designed for superior stability and vibration resistance

- Ensures maintained accuracy over time

- Ideal for high-precision industrial applications

- User-friendly interface for easy operation

- Reduced material waste due to precise cutting

- Suitable for both small-scale and large-volume production runs

- Low maintenance requirements, ensuring long-term reliability

Features:

- Precision Cutting

- Irregular shape high-speed cutting

- Contour cutting

- Small hole drilling

- Hand-held cutting capabilities

- Superior Processing

- High-quality edge finishing

- No taper effects

- Minimal material loss

- Burr-free cutting

- Eco-Friendly Operation

- No pollution

- No powder residue

- No wastewater production

- High-Speed Processing

- Rapid cutting of complex shapes and patterns

- Superior Cut Quality

- Clean edges with no tapering

- Minimal to no burrs

- Extremely small chipping, if any

- Cost-Effective

- High yield rate

- Low consumable usage

- Energy-efficient operation

- Environmentally Friendly

- Clean process with no harmful byproducts

- Specialized Glass

- Ultra-clear glass

- Plain white glass

- High borosilicate glass

- Quartz glass

- Electronic Components

- Phone glass covers

- Car glass

- Camera glass covers

- LCD screens

- Optical Materials

- K9 glass

- Various optical filters

- Mirror cutting

- Precious Materials

- Sapphire processing for watch faces and electronic components

- Glass Manufacturing

- Optical glass

- Tempered glass

- Ultra-thin glass

- Laboratory glassware

- Medical glass equipment

- Electronics

- Mobile phone screens and covers

- Tablet displays

- Laptop screens

- Optical/ITO/Yellow/Purple semiconductor glass

- Automotive

- Car windows and windshields

- Dashboard displays

- Instrumentation panels

- Real Estate and Construction

- Architectural glass

- Decorative glass panels

- Bathroom glass fixtures

- Home Appliances

- Glass panels for ovens and refrigerators

- Lighting glass components

- Communication Media

- Mobile device screens

- Watch sapphire covers

- Camera and CCTV lenses

- New Energy Sector

- Solar panel glass

- Specialized glass for energy-efficient windows

- Aerospace and Defense

- High-precision optical components

- Specialized glass for cockpit displays

- Medical and Scientific Research

- Laboratory equipment glass

- Optical lenses for medical devices

- Microfluidic chips

This advanced laser cutting system offers a versatile solution for a wide range of industries, providing high-precision, efficient, and eco-friendly processing of various glass and optical materials. Its ability to handle complex shapes and delicate materials makes it an ideal choice for both large-scale manufacturing and specialized, high-value applications.

Technical Parameters:

The lasers we offer are ultrashort pulse fiber lasers, with the specific type varying by model. The average power available ranges from 10W to 80W, with our standard model offering 50W of power. The laser has a wavelength of 1064nm, with a second harmonic at 532nm. The pulse width is less than 10 picoseconds, and the repetition rate is adjustable from 1Hz to 1000kHz. The beam quality is near-diffraction-limited, with M² < 1.2.

Our lasers offer exceptional cutting performance, with a positioning accuracy of ±2μm over the entire work area. The repeatability is ±1.5μm, with ±16 arc-seconds angular accuracy. Maximum cutting speed can reach up to 1000mm/s, and the laser can cut ultra-thin glass up to 1mm thick and standard glass up to 19mm thick depending on material properties and cutting requirements.

The minimum line width is less than or equal to 30μm, and the minimum hole diameter is less than or equal to 20μm.

We offer both dual-platform models and single-platform models, with the work area dimensions varying by model. Our dual-platform models come in three sizes: 600x700mm, 600x900mm, or 400x500mm per platform. Our single-platform models come in three sizes: 400x500mm, 600x700mm, or 600x900mm.

Our lasers have a power consumption of 150W, with standby modes at 250W or 350W. The input voltage is AC220V ± 10%, and the frequency is 50-60Hz.

Our machines have varied physical specifications based on model type. The length of the machines range from 1600mm to 2550mm and the width from 1700mm to 2080mm. The machines are 1960mm in height and have a weight ranging from 3500kg to 5000kg depending on the model.

In addition to the exceptional performance of our laser machines, we have included additional features to enhance the user experience and safety. Our laser machines come complete with a built-in water cooling system for optimal thermal stability. We also include advanced CNC control systems and proprietary cutting optimization software. Our machines feature a Class 1 laser safety enclosure, as well as emergency stop buttons for added safety.

For optimal performance, our laser machines require an operating temperature of 18-28°C (64-82°F) and a humidity level of 40-70% non-condensing. The power stability should not fluctuate more than ±5%.

We offer optional upgrades to further enhance the capabilities of our laser machines. Enhancements include an enhanced vision system for automatic alignment, an automated material loading/unloading system, and custom fixture designs for specific applications. We also offer extended warranty and service packages for added peace of mind.

Please note that specifications may vary slightly based on specific configurations and continuous product improvements, so please consult with our technical team for the most up-to-date information and customization options.

Applications:

Our state-of-the-art laser cutting machine is designed to meet a diverse range of industrial needs, offering precision and efficiency across various materials and applications:

- Ideal for creating high-precision instrument panels, dashboards, and control interfaces

- Capable of handling thin to medium-thickness materials with exceptional accuracy

Our laser cutting system is capable of precise cutting for a variety of glass types:

- Ultra-thin Glass: For delicate glass sheets used in electronic devices

- White Glass: For accurate and clean processing in decorative and architectural applications

- High-Borosilicate Glass: For specialized cutting of laboratory equipment and heat-resistant products

- Quartz Glass: For precision cutting used in optical components and the semiconductor industry

- Tailored for cutting PCB boards, flexible circuits, and other electronic substrates

- Ensures clean edges and minimal thermal impact on sensitive electronic materials

Our laser cutting system is capable of specialized cutting for a variety of gemstones and precious materials:

- Sapphire Cutting: For high-end displays, watch faces, and smartphone camera lenses

- Precision Gemstone Shaping: For creating intricate designs in precious and semi-precious stones

- LED Component Manufacturing: For cutting sapphire wafers used in LED production

Our laser cutting system is capable of precise cutting for various LCD components:

- ITO (Indium Tin Oxide) conductive films

- RGB color filters

- Polarizing films

Ensures precise cutting without damaging delicate display materials.

Our laser cutting system is capable of accurate cutting and precision shaping for various optical materials:

- K9 optical glass for high-quality lenses and prisms

- Optical films for various industrial and scientific applications

- Micro-cutting of small, intricate parts for the medical and aerospace industries

- Custom shape cutting for unique product designs and prototypes

- Multi-layer material processing for composite products

With its versatility, our laser cutting system is invaluable across various industries, from consumer electronics to advanced scientific research. It ensures high-quality results and efficient production processes.