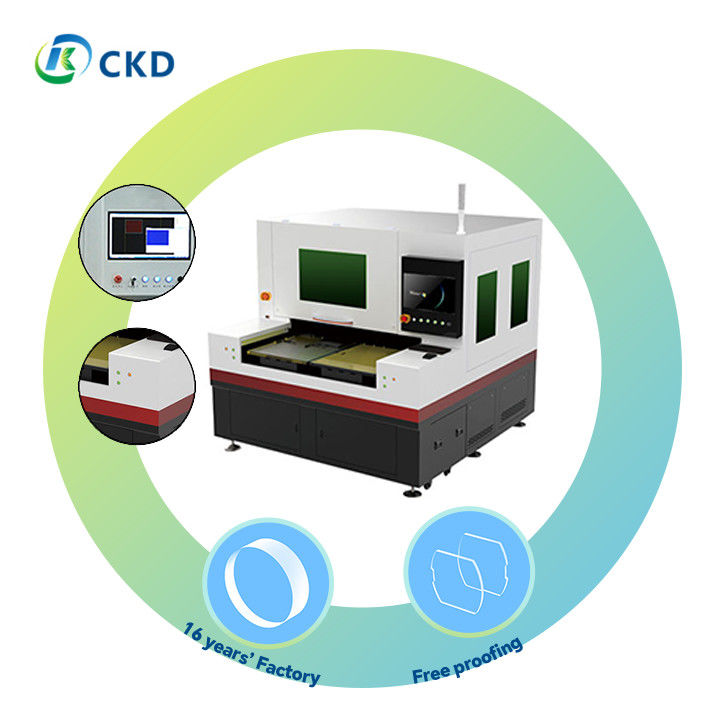

Industrial-Grade Laser Glass Cutting Machine for Heavy-Duty Applications 0.1mm

-

Highlight

Industrial Grade Laser Glass Cutting Machine

,0.1mm Laser Glass Cutting Machine

,Heavy Duty Laser Glass Cutting Machine

-

Minimum Cutting Burr≤5um

-

Weight3500kg

-

Splitting Laser Source Wavelength10.6µm

-

Splitting Laser Source Pulse Frequency1-100kHz

-

Dimension2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm

-

Cutting Area1300mm X 2500mm

-

Beam QualityM² < 1.2

-

Wavelength1064nm

-

Cutting Accuracy±0.01mm

-

Cutting Precision±0.01mm

-

Working Area1500mm X 3000mm

-

Laser80W

-

Machine Weight2000KG

-

Applicable MaterialAcrylic, Glass, Paper, Plastic, Crystal

-

ThicknessLess Than 25mm

-

Laser Wavelength1064nm

-

Transmission SystemLinear Guide Rail

-

Cooling SystemWater Cooling

-

Power50W/80W

-

Accuracy±0.01mm

-

Cutting Speed0-30m/min

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Industrial-Grade Laser Glass Cutting Machine for Heavy-Duty Applications 0.1mm

Product Description:

The Laser Glass Cutting Machine operates with an impulse frequency of 1-100kHz, which allows for high precision and accuracy when cutting glass. The cutting precision of this machine is ±0.01mm, ensuring that every cut is clean and precise.

This Environmental protection glass laser cutting machine is energy-efficient and has eco-friendly modes. The standby power is about 500W, and the average power consumption during cutting is 2.5kW. This makes it an environmentally friendly option for those who are conscious of their carbon footprint.

The Laser Glass Cutting Machine is equipped with a splitting laser source power of 150W, with options for 250W or 350W. This makes it a powerful cutting tool for any type of glass material.

The control system of this machine is HTI Control, which ensures that the machine is easy to operate and highly efficient. This means that users can get the job done quickly and with minimal effort.

In summary, the Laser Glass Cutting Machine is a powerful and precise tool for anyone working with glass materials. Its high impulse frequency, cutting precision, and energy efficiency make it an ideal option for those who want to get the job done quickly and with minimal environmental impact.

Features:

- Product Name: Laser Glass Cutting Machine

- Energy Consumption: Standby Power Is About 500W, And Average Power Consumption During Cutting Is 2.5kW. Energy-efficient With Eco-friendly Modes.

- Maintenance Requirements: Recommend Optical Alignment Every 200 Hours, And Coolant Replacement Every 1000 Hours. Regular Remote Diagnostics And Software Updates Available.

- Pulse Frequency: 1Hz - 1000kHz

- Cutting thickness: 0.03~25mm

- Cutting Thickness: Ultra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm

- Type: Single Table Glass Cutting Machine

- Also known as: Stained glass cutting machine, Fiber Laser Cutting Machine

Technical Parameters:

| Environmental Conditions | Works Best In Temperatures Between 15°C And 30°C, With 20%-80% Relative Humidity, Suitable For Cleanrooms Or Industrial Environments |

| Splitting laser source Cooling Method | Water Cooling |

| Splitting laser source Laser Type | RFC02 (Radio Frequency CO2) |

| Advantages | Irregular-shape High-speed Cutting High Cutting Quality, No Taper, No Burr, Small Chipping High Yield Rate, Low Consumables And Energy-saving No Pollution, No Powder, And No Wastewater |

| Cutting Area | 400mm*500mm/ 600*700mm/ 600*900mm |

| Acceleration | 1G |

| Cutting Thickness | Ultra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm |

| Beam Quality | M² < 1.2 |

| Energy Consumption | Standby Power Is About 500W, And Average Power Consumption During Cutting Is 2.5kW. Energy-efficient With Eco-friendly Modes. |

Applications:

The CKD Laser Glass Cutting Machine is available in several models, including the CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50E, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80E, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80E, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80E, CKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80E, CKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E. Each model has different specifications, but all are capable of providing high-quality cuts on a variety of glass types.

The CKD Laser Glass Cutting Machine is an ideal solution for a variety of product application occasions and scenarios. This machine is perfect for use in the production of stained glass, as it is capable of cutting intricate shapes and designs with ease. It is also a great choice for the production of fiber laser cutting machines, as it is capable of cutting a variety of glass types with precision and accuracy.

The CKD Laser Glass Cutting Machine is manufactured in China and is certified by ISO CE. The minimum order quantity is 1, and the price is negotiated. The machine is delivered in wooden vacuum packaging and has a delivery time of 25-45 days. Payment terms include L/C and T/T, and the supply ability is 60 sets per month.

Maintenance of the CKD Laser Glass Cutting Machine is straightforward. It is recommended that optical alignment is performed every 200 hours, and coolant replacement is done every 1000 hours. Regular remote diagnostics and software updates are available. The machine has a dimension of 2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm, and the linear guide brand used is TPI.