Upgrade Your Cutting Process with Our High-Performance Laser Glass Cutting Machine To Chipping ≤5μm

-

Support Image And Text FormatsAI PLT DXF BMP Dst DWg LAS DXP

-

Energy ConsumptionStandby Power Is About 500W, And Average Power Consumption During Cutting Is 2.5kW. Energy-efficient With Eco-friendly Modes.

-

Cutting Speed0-600mm/s

-

Impulse Frequency1-100khz

-

Cutting Precision±0.01mm

-

Drive MotorXY Linear Motor + Grating Ruler

-

MaterialGlass

-

MobilityEquipped With Heavy-duty Wheels For Easy Movement And Repositioning, With Locking Mechanisms For Stability

-

Control SystemCNC

-

Overall Dimensions4500mm*2500mm*1500mm

-

Linear Guide BrandTPI

-

ApplicationGlass Cutting, Glass Engraving

-

Driving SystemStepper Motor

-

Working TableHoneycomb/Aluminum Blade

-

Beam QualityM^2 < 1.2

-

Whether CncYes

-

Cutting Size40*50cm*2

-

Supported File FormatsAI, PLT, DXF, BMP, DST, DWG, DXP

-

Laser Wavelength1064nm

-

Power1000W

-

Acceleration1G

-

Cooling MethodWater Cooling

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Upgrade Your Cutting Process with Our High-Performance Laser Glass Cutting Machine To Chipping ≤5μm

Product Description:

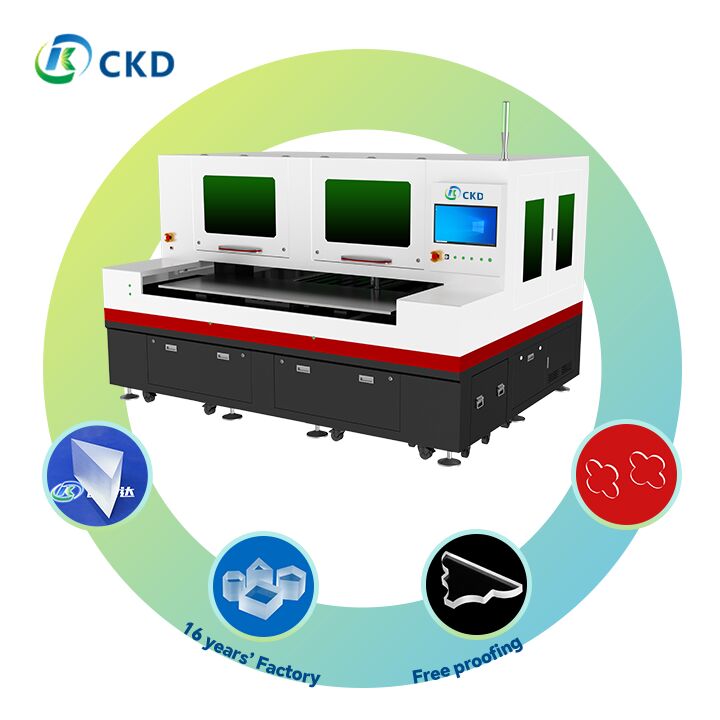

The Laser Glass Cutting Machine is an advanced, high-precision tool designed to meet the diverse needs of glass processing industries. This state-of-the-art equipment excels in cutting various types of glass with exceptional accuracy and efficiency. Whether you require ultra-clear glass cutting or specialized stained glass processing, this machine offers unparalleled performance, making it an indispensable asset for manufacturers and artisans alike.

One of the standout features of this laser glass cutting machine is its impressive cutting thickness capability. For ultra-clear glass, it supports single cuts up to 19mm, ensuring clean, precise edges without compromising the integrity of the material. Additionally, it can handle blue glass with double cuts up to 19mm, providing versatility for different glass types and applications. This flexibility makes it an excellent choice for those working with both standard and stained glass, as it can seamlessly switch between tasks without sacrificing quality.

Precision is critical in glass cutting, and this machine delivers with an outstanding cutting accuracy of ±0.01mm. This level of precision ensures that every cut is exact, reducing waste and enhancing the final product’s quality. Such accuracy is vital for industries requiring intricate designs or tight tolerances, such as decorative glass manufacturing or architectural applications. The machine’s reliable precision also makes it ideal as a small glass laser cutting machine for businesses that need compact yet highly effective cutting solutions.

Durability and reliability are guaranteed with the included 2-year warranty that covers major components such as the laser source and control system. This warranty offers peace of mind, knowing that your investment is protected against manufacturing defects and operational issues. Furthermore, the product comes with comprehensive 24/7 technical support, featuring both remote assistance and on-site service options. This ensures minimal downtime and rapid resolution of any technical challenges, keeping your production line running smoothly and efficiently.

The operational environment for the laser glass cutting machine is optimized for consistent performance. It is designed to function best at a working temperature of 26℃, which helps maintain stability and precision during extended use. Additionally, the machine features a built-in silencing system that keeps the operating noise level at a modest 70dB. This low noise output is particularly advantageous for settings where noise reduction is essential, making it suitable for workshops and production environments that prioritize a quieter workspace.

As a single table glass cutting machine, it offers a streamlined and user-friendly interface that enhances productivity. Its design facilitates easy loading and unloading of glass sheets, enabling operators to work efficiently without unnecessary delays. The compact footprint of this small glass laser cutting machine also makes it a practical choice for facilities with limited space, without compromising on cutting power or precision.

For stained glass artisans, this machine serves as a specialized stained glass cutting machine capable of handling delicate and complex patterns with finesse. The laser technology ensures smooth edges and reduces the risk of glass breakage, which is crucial when working with artistic and decorative pieces. This capability opens up new creative possibilities for designers and craftsmen, allowing for intricate designs that were previously difficult to achieve with traditional cutting methods.

In summary, the Laser Glass Cutting Machine combines cutting-edge technology, high precision, and robust support to offer a comprehensive solution for glass cutting needs. Its ability to handle various glass types and thicknesses, combined with a reliable warranty and low-noise operation, makes it an ideal investment for businesses seeking efficiency and quality. Whether you are looking for a single table glass cutting machine, a stained glass cutting machine, or a small glass laser cutting machine, this product stands out as a versatile and dependable choice that will elevate your glass processing capabilities.

Features:

- Product Name: Laser Glass Cutting Machine

- Brand: CKD

- Laser Type: Infrared Picosecond

- Laser Wavelength: 1064nm

- Beam Quality: M² < 1.2

- Weight: 3500kg

- High Precision Laser Cutting Machine for superior accuracy

- Ideal for Small Glass Laser Cutting Machine applications

- Capable of cutting colored glass with excellent results

Applications:

The CKD Laser Glass Cutting Machine series, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, and many others, is designed to meet the diverse needs of modern glass processing industries. Originating from China and certified with ISO and CE standards, these machines offer exceptional reliability and performance. With a minimum order quantity of just one unit and customizable options for table size, laser power up to 500W, and special cutting heads for curved or micro-level cutting, the CKD laser glass cutting machines are adaptable to various production demands.

These high precision laser cutting machines are ideal for industrial applications that require ultra-clear glass cutting with single cut thicknesses up to 19mm and blue glass double cut thicknesses up to 19mm. The cutting area options range from 400mm*500mm to 600mm*900mm, providing flexibility for different project sizes. With an impressive positioning accuracy of ±2μm and an impulse frequency range of 1-100kHz, the CKD models ensure precise and consistent results, making them perfect for intricate designs and detailed glass work.

The CKD laser glass cutting machines excel in irregular glass cutting tasks, which are often challenging with traditional cutting methods. These machines can handle complex shapes and patterns with ease, thanks to their advanced laser technology and customizable cutting heads. This makes them highly suitable for industries such as automotive glass manufacturing, architectural glass design, decorative glass production, and electronic display panel fabrication.

Moreover, the environmental protection glass laser cutting machine design ensures minimal waste and reduces the environmental impact compared to conventional mechanical cutting methods. The laser cutting process is clean, with no physical contact or mechanical stress on the glass, preserving its integrity and reducing defects. Wooden vacuum packaging guarantees safe delivery within 25-45 days, and payment terms like L/C and T/T provide flexible purchasing options.

With a supply ability of 60 sets per month and a negotiable price, CKD’s laser glass cutting machines are a cost-effective investment for businesses looking to improve cutting precision, efficiency, and environmental sustainability. Whether for regular production runs or custom projects requiring specialized cutting solutions, these machines offer unmatched performance and versatility in the glass processing industry.

Customization:

CKD offers a range of Laser Glass Cutting Machines, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50E, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80E, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80E, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80E, CKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80E, CKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E. Manufactured in China and certified with ISO and CE, these machines are designed for precision and reliability.

Our Laser Glass Cutting Machines are ideal for various applications including polygonal glass cutting machine, stained glass cutting machine, and optical glass laser cutting machine tasks. They feature an ultra-fast picosecond laser capable of linear speeds up to 1000mm/s with acceleration of 1G, driven by XY linear motors combined with optical grating scales for enhanced accuracy.

Each unit is equipped with heavy-duty wheels for easy movement and repositioning, along with locking mechanisms to ensure stability during operation. The machines are securely packed using wooden vacuum packaging to guarantee safe delivery. With a supply ability of 60 sets per month, we accommodate minimum order quantities starting from just 1 set.

Pricing is negotiable to meet customer requirements, and delivery time ranges from 25 to 45 days. Payment terms include L/C and T/T methods, providing flexibility and convenience. Trust CKD’s Laser Glass Cutting Machines for advanced technology and superior performance in your glass processing needs.

Support and Services:

Our Laser Glass Cutting Machine is designed to provide precise and efficient cutting solutions for various types of glass materials. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services.

Installation and Setup: Our team provides detailed guidance and on-site assistance for the installation and initial setup of your laser glass cutting machine, ensuring it operates correctly from the start.

Training: We offer thorough training sessions for operators to familiarize them with the machine's features, safety protocols, and maintenance procedures to maximize productivity.

Maintenance and Repairs: Regular maintenance services are available to keep your machine running smoothly. In case of any technical issues, our expert technicians are ready to diagnose and repair your machine promptly.

Software Support: We provide updates and technical support for the machine’s software to enhance functionality and resolve any software-related issues.

Spare Parts Supply: Genuine spare parts are available to replace worn or damaged components, ensuring the machine maintains its cutting precision and reliability.

Consultation Services: Our specialists are available to offer advice on optimizing cutting processes, selecting appropriate settings, and integrating the machine into your production line.

Customer Service: Dedicated support is provided to address any inquiries or concerns related to the laser glass cutting machine, ensuring customer satisfaction and continuous operational efficiency.