Maximize Your Glass Cutting Efficiency with Laser Glass Cutting Machine To Speed 0-500mm/s

-

Splitting Laser SourceRFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W (options: 250W/350W) - 150W(250W/350W) 1-100kHz Water Cooling

-

Pulse Width<10ps

-

MaterialGlass

-

Noise LevelOperating Noise Level Is 70dB, With A Built-in Silencing System, Suitable For Low-noise Environments.

-

Control SystemHTI Control

-

Splitting Laser Source Laser TypeRFC02 (Radio Frequency CO2)

-

Cutting Precision±0.01mm

-

Acceleration1G

-

Trade NameGlass Laser Cutting Machine

-

SoftwareLaserCut

-

Optional AccessoriesRotary Attachment, Red Dot Pointer

-

AdvantagesSmall Chipping

-

Whether CncYes

-

Machine Dimensions4300mm X 2300mm X 1500mm

-

Minimum Cutting Burr≤5um

-

Power SupplyAC 380V/50Hz

-

Machine Weight2000KG

-

MaterialsQuartz Glass

-

Working TableHoneycomb/Aluminum Blade

-

Laser Source BrandRAYCUS

-

Cutting Size40*50cm*2

-

Chipping≤5μm

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Maximize Your Glass Cutting Efficiency with Laser Glass Cutting Machine To Speed 0-500mm/s

Product Description:

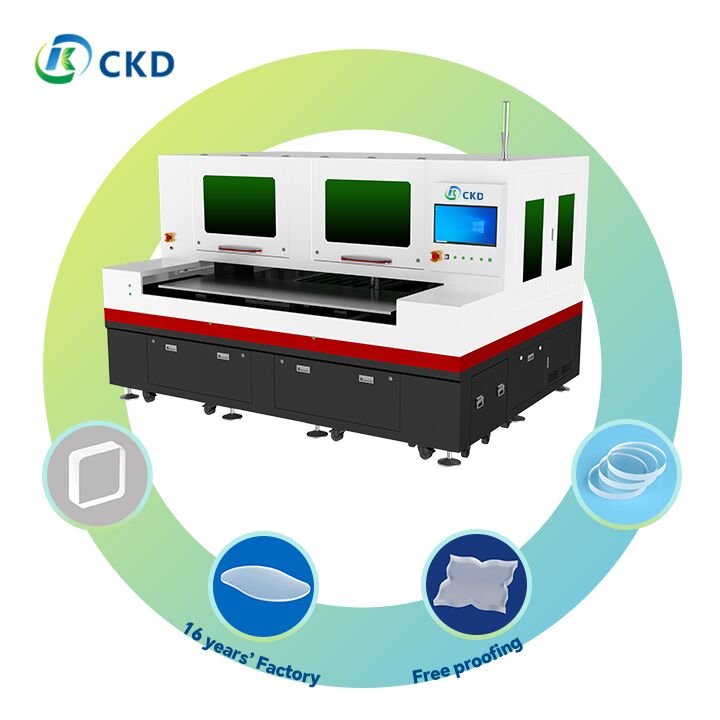

The Laser Glass Cutting Machine is a state-of-the-art solution designed to meet the diverse needs of industries requiring high precision and efficiency in glass processing. This small glass laser cutting machine is engineered to deliver exceptional performance, combining advanced technology with customizable features to handle a wide range of glass cutting applications, including irregular glass cutting with remarkable accuracy and speed.

One of the standout features of this laser glass cutting machine is its impressive impulse frequency range of 1-100 kHz. This broad frequency spectrum allows the machine to operate with great flexibility, adapting to different types of glass materials and thicknesses. Whether you are working on ultra-clear glass or blue glass, the machine’s high-frequency laser pulses ensure clean and precise cuts without compromising the integrity of the glass.

Customization is a key highlight of this product. Customers can tailor the table size to fit their workspace and production requirements, making it an ideal choice for various operational scales. Additionally, the laser power is adjustable up to 500W, providing the necessary strength for cutting thicker or more challenging glass types. For specialized applications, the machine can be equipped with special cutting heads designed for curved or micro-level cutting, enabling intricate designs and detailed work with unparalleled precision. This feature is particularly useful for irregular glass cutting tasks, where conventional cutting methods often fall short.

Precision is critical in glass cutting, and this machine excels with a cutting precision of ±0.01mm. Such high accuracy ensures that every piece of glass is cut exactly to specification, minimizing waste and improving the quality of the final product. This level of precision is essential for industries such as electronics, automotive, and architecture, where exact dimensions are crucial.

The cutting thickness capabilities of the machine are equally impressive. It can handle ultra-clear glass single cuts of up to 19mm thickness and blue glass double cuts up to 19mm as well. This versatility makes it suitable for a broad range of glass types and thicknesses, providing users with a comprehensive solution for their glass cutting needs.

In terms of size, the machine is available in two dimension options: 2150mm × 2080mm × 1960mm and 2550mm × 2080mm × 1960mm. These dimensions ensure that the machine occupies a reasonable footprint while still offering a spacious working area to accommodate various glass sizes. This balance between size and functionality makes it an excellent choice for facilities with limited space but demanding production requirements.

Beyond its technical specifications, the small glass laser cutting machine is designed with user convenience in mind. Its intuitive controls and reliable operation reduce the learning curve and enhance productivity. The machine’s ability to perform irregular glass cutting efficiently opens up new possibilities for creative and complex glass designs that were previously difficult or impossible to achieve.

In summary, this Laser Glass Cutting Machine is a powerful, precise, and customizable tool ideal for businesses that require advanced glass cutting capabilities. Its high impulse frequency, adjustable laser power, specialized cutting heads, and exceptional precision make it a versatile choice for a wide range of applications. Whether cutting ultra-clear or blue glass, handling standard shapes, or performing irregular glass cutting, this machine meets the highest standards of quality and performance. Its thoughtful design and customizable options ensure that it can be tailored to meet specific industrial needs, making it a valuable investment for any glass processing operation.

Features:

- Product Name: Laser Glass Cutting Machine

- Working Environment: 26℃

- Control System: HTI Control

- Mobility: Equipped with heavy-duty wheels for easy movement and repositioning, with locking mechanisms for stability

- Applicable Industries:

- Glassware Industry: Optical Glass, K9 Glass, and Ultra-thin Glass

- Houseware Industry: High-borosilicate Glass, Quartz Glass, Sanitary Ware Glass

- Vehicle Industry: Automotive Glass, Car Windshield, etc.

- New Energy: Photovoltaic Glass

- Home Appliance: Home Appliance Glass, Panel Lighting Glass

- Real Estate: Architectural Decoration, Bathroom Glass, etc.

- Cutting Width: 0.03-25mm

- Features:

- Fiber Laser Cutting Machine technology for enhanced cutting efficiency

- High Precision Laser Cutting Machine ensuring accurate and clean cuts

- Environmental Protection Glass Laser Cutting Machine designed for eco-friendly operation

Applications:

The CKD Laser Glass Cutting Machine series, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-SP6070S-50E, CKD-SP6070S-60E, and many others, is designed to meet a wide range of application occasions and scenarios. Originating from China and certified with ISO and CE standards, these machines are ideal for industries requiring ultra-precise and efficient glass cutting solutions.

One of the primary application occasions for the CKD High Precision Laser Cutting Machine is in the manufacturing of architectural and decorative glass products. Its exceptional cutting precision of ±0.01mm and adjustable cutting speed up to 500mm/s make it perfect for producing ultra-clear glass panels, colored glass, and specialty glass components with intricate designs and high-quality edges. Whether it is single-cut ultra-clear glass up to 19mm thick or double-cut blue glass, this machine handles them with unmatched accuracy and speed.

In addition, the CKD Single Table Glass Cutting Machine models offer a reliable and user-friendly solution for small to medium-sized workshops and factories focusing on customized glass products. The standard work size of 610*700mm (customizable upon request) allows for versatile cutting tasks, from decorative glass art pieces to functional glass parts for electronics, automotive, and household appliances. The ability to support a wide range of image and text formats, including AI, PLT, DXF, BMP, Dst, DWg, LAS, and DXP, ensures seamless integration with design software and enhances production flexibility.

Moreover, the colored glass cutting machine variants in the CKD lineup cater to industries that demand precision cutting of tinted or colored glass used in interior decoration, stained glass windows, and custom glass furniture. The vacuum wooden packaging guarantees safe shipment, while the supply ability of 60 sets per month and delivery time of 25-45 days provide an efficient procurement process. Payment terms such as L/C and T/T add to the convenience for global buyers.

Overall, the CKD Laser Glass Cutting Machine series is perfectly suited for glass processing factories, glass product manufacturers, custom glass workshops, and design studios that prioritize accuracy, efficiency, and versatility. Its advanced laser cutting technology, combined with robust build quality and comprehensive certification, makes it an indispensable tool for achieving high-quality glass cutting results in diverse industrial and artistic applications.

Customization:

Introducing the CKD Laser Glass Cutting Machine, a high-precision single table glass cutting machine designed for various applications including ultra clear glass, optical glass, and more. With model numbers ranging from CKD-DP6070C-50E to CKD-SP6070C-80E, this machine offers versatile cutting areas of 400mm*500mm, 600*700mm, and 600*900mm to meet diverse project requirements.

Manufactured in China and certified with ISO and CE standards, the CKD laser glass cutting machine ensures top quality and reliability. The minimum order quantity is just 1 set, with prices available upon negotiation. Each unit is carefully packed using wooden vacuum packaging to guarantee safe delivery within 25-45 days.

The CKD optical glass laser cutting machine supports cutting of a wide range of materials including ultra clear glass, plain white glass, high borosilicate glass, quartz glass, optical glass, phone glass covers, car glass, LCD screens, K9 glass, filters, mirrors, and more. Weighing 3500kg, the machine is robust and built for industrial use with a supply ability of 60 sets per month.

Payment terms include L/C and T/T options for flexible transactions. Our machines come with a comprehensive 2-year warranty covering major components like the laser source and control system. Additionally, 24/7 technical support is available with both remote and on-site service options to ensure your operations run smoothly.

Choose CKD for your optical glass laser cutting machine needs and experience precision, efficiency, and excellent after-sales service in every single table glass cutting machine we provide.

Support and Services:

Our Laser Glass Cutting Machine is designed to deliver precision and efficiency for all your glass processing needs. To ensure optimal performance and longevity of the machine, we provide comprehensive technical support and services.

Technical Support:

We offer expert technical support to assist you with installation, setup, and operation of the Laser Glass Cutting Machine. Our team of specialists is available to help troubleshoot any issues, provide software updates, and guide you through maintenance procedures to keep your machine running smoothly.

Training Services:

To maximize your investment, we provide training sessions for your staff, covering machine operation, safety protocols, and basic maintenance. This training ensures that your team can operate the machine efficiently and safely.

Maintenance and Repair:

Regular maintenance is crucial for the longevity of your Laser Glass Cutting Machine. We offer scheduled maintenance services to check and calibrate the machine components. In the event of any malfunction, our repair services are available to minimize downtime and restore your machine to full functionality promptly.

Spare Parts and Accessories:

We supply genuine spare parts and accessories specifically designed for the Laser Glass Cutting Machine. Using authentic parts ensures compatibility and maintains the quality and precision of your cutting operations.

Software Support:

Our product includes advanced software for controlling the cutting process. We provide software updates and technical assistance to help you utilize the latest features and improvements.

Extended Warranty and Service Contracts:

For added peace of mind, we offer extended warranty options and service contracts tailored to your usage needs. These plans provide priority support and cost-effective maintenance solutions.

Customer Satisfaction:

Your satisfaction is our priority. We are committed to providing timely and effective support to ensure that your Laser Glass Cutting Machine operates at its best, helping you achieve superior cutting results and productivity.