Experience Superior Glass Cutting Results with Our Laser Glass Cutting Machine To Accuracy±0.01mm

-

Customizable OptionsCustom Options Available For Table Size, Laser Power (up To 500W), And Special Cutting Heads (like For Curved Or Micro-level Cutting) To Meet Specific Needs.

-

Positioning Accuracy±2μm

-

Splitting Laser Source Wavelength10.6µm

-

Cutting Accuracy±0.01mm

-

Impulse Frequency1-100khz

-

Applicable MaterialsUltra Clear Class, Plain White Glass High Borosilicate Glass, Quartz Glass Optical Glass, Cover Glass, Camera Glass Cover, Etc. Phone Glass Cover, Car Glass, Camera Glass Cover, Etc. LCD Screen, K9 Glass, Filter Cutting, Mirror Cutting, Etc.

-

Linear Guide BrandTPI

-

Splitting Laser Source Laser TypeRFC02 (Radio Frequency CO2)

-

Weight3500kg

-

MaterialsGlass, Acrylic, Metal, Etc.

-

Laser Wavelength1064nm

-

Machinery Efficiency0-500mm/s

-

Applied RangeGlass

-

Drive MotorXY Linear Motor + Grating Ruler

-

Power SupplyAC 220V/380V, 50/60Hz

-

Drilling Thickness<19mm

-

Whether CncYes

-

Machine Size1700mm*1700mm*1960mm

-

Laser Power1000W

-

Chipping≤200μm

-

Working Voltage220V/380V

-

After-Sales ServiceOnline Support, Field Installation, Commissioning And Training, Video Technical Support

-

NaneGlass Laser Cutting Machine

-

Place of OriginChina

-

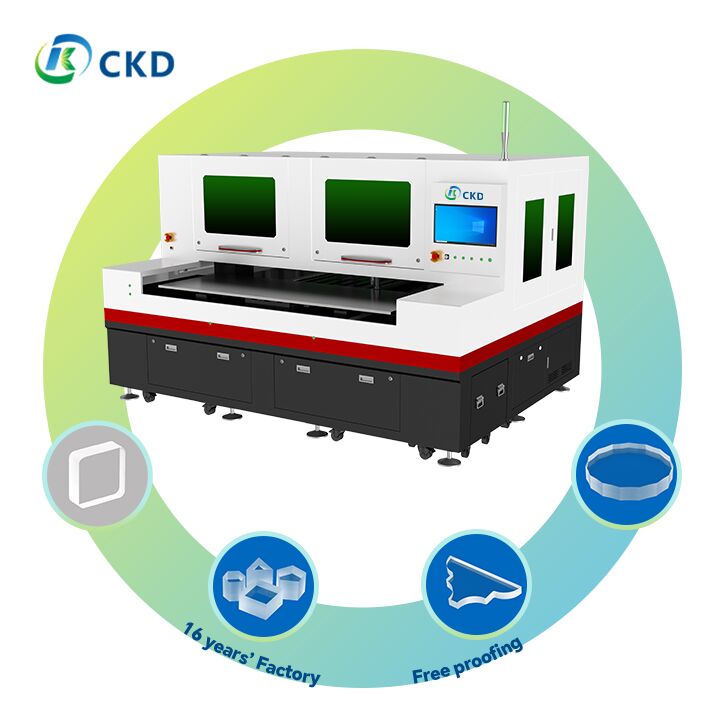

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Experience Superior Glass Cutting Results with Our Laser Glass Cutting Machine To Accuracy±0.01mm

Product Description:

The Laser Glass Cutting Machine is an advanced fiber laser cutting machine specifically designed for precision cutting of glass materials. Combining cutting-edge technology with robust engineering, this machine delivers exceptional performance, making it ideal for industries requiring high accuracy and superior quality in glass processing. Whether you are working with thin or thick glass, this environmental protection glass laser cutting machine ensures minimal cutting burrs, with a minimum cutting burr size of ≤5μm, resulting in clean, smooth edges that require little to no post-processing.

Constructed to handle a variety of glass types, this thick glass laser cutting machine offers unparalleled precision and efficiency. Its capability to process thick glass sheets with minimal waste and high repeatability makes it a valuable asset for manufacturers in sectors such as electronics, automotive, architecture, and decorative glass production. The integration of fiber laser technology provides high power density and excellent beam quality, allowing for fast, accurate cutting with reduced thermal impact on the glass, preserving its structural integrity and aesthetic appeal.

Dimensionally, this fiber laser cutting machine comes in two configurations to suit different workspace requirements: 2150mm × 2080mm × 1960mm and 2550mm × 2080mm × 1960mm. These versatile dimensions ensure that the machine can be seamlessly integrated into various production lines, accommodating different sizes of glass sheets and optimizing floor space utilization. Despite its substantial size, the machine is engineered for ease of operation and maintenance, featuring a user-friendly CNC control system that automates the cutting process with precision and repeatability.

Environmental considerations have been thoughtfully incorporated into the design of this environmental protection glass laser cutting machine. It operates best in controlled environments with temperatures ranging between 15°C and 30°C and relative humidity levels from 20% to 80%. These parameters make it suitable for cleanrooms or industrial environments, ensuring stable performance and longevity of the machine components. The machine’s design emphasizes sustainability by minimizing energy consumption and reducing material waste, aligning with modern environmental protection standards.

The CNC functionality of this laser glass cutting machine enhances its versatility and efficiency. Computer numerical control enables precise programming of cutting paths, speeds, and laser power settings, allowing for complex and intricate designs to be executed with high accuracy. This automation reduces human error, increases production speed, and allows for easy replication of cutting patterns, making it ideal for both prototype development and large-scale manufacturing.

In addition to its technical specifications, the fiber laser cutting machine is built with durability and safety in mind. Its robust frame and protective enclosures ensure stable operation even under continuous use, while safety features protect operators from laser exposure and mechanical hazards. The machine’s intuitive interface and support for various software platforms facilitate seamless integration into existing workflows, enhancing overall productivity.

To summarize, the Laser Glass Cutting Machine is a state-of-the-art fiber laser cutting solution designed for precise, efficient, and environmentally conscious glass cutting. Its minimal cutting burr size of ≤5μm guarantees superior edge quality, while its suitability for both thin and thick glass makes it versatile across multiple applications. With dimensions tailored to different production needs and optimal operation in controlled environmental conditions, this CNC-enabled environmental protection glass laser cutting machine stands out as an essential tool for modern glass manufacturing industries. Whether for industrial or cleanroom settings, this machine delivers consistent, high-quality results, promoting innovation and sustainability in glass processing.

Features:

- Product Name: Laser Glass Cutting Machine

- Acceleration: 1G

- Cutting Precision: ±0.01mm

- Impulse Frequency: 1-100kHz

- Applicable Materials:

- Ultra Clear Glass

- Plain White Glass

- High Borosilicate Glass

- Quartz Glass

- Optical Glass

- Cover Glass

- Camera Glass Cover

- Phone Glass Cover

- Car Glass

- LCD Screen Glass

- K9 Glass

- Filter Glass

- Mirror Glass

- Applicable Industries:

- Glassware Industry:

- Optical Glass

- K9 Glass

- Ultra-thin Glass

- Houseware Industry:

- High-borosilicate Glass

- Quartz Glass

- Sanitary Ware Glass

- Vehicle Industry:

- Automotive Glass

- Car Windshield

- New Energy:

- Photovoltaic Glass

- Home Appliance:

- Home Appliance Glass

- Panel Lighting Glass

- Real Estate:

- Architectural Decoration Glass

- Bathroom Glass

- Glassware Industry:

- Machine Types:

- Single Table Glass Cutting Machine

- Small Glass Laser Cutting Machine

- Polygonal Glass Cutting Machine

Applications:

The CKD series of Laser Glass Cutting Machines, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, and many others, are engineered to meet the diverse needs of modern glass processing industries. Manufactured in China and certified with ISO and CE standards, these machines offer reliable, high-precision cutting solutions for various types of glass materials. Their advanced optical glass laser cutting capabilities make them ideal for applications requiring exceptional accuracy and minimal chipping, with a chipping size of ≤5μm ensuring superior edge quality.

One of the primary application occasions for CKD laser glass cutting machines is in the production of optical components. The optical glass laser cutting machine models are specially designed to handle delicate optical glass with great precision, making them perfect for industries such as lens manufacturing, optical instruments, and high-tech electronics. The laser cutting technology supports intricate designs and micro-level cutting, which is essential for producing high-quality optical elements.

Colored glass cutting is another significant scenario where CKD’s colored glass cutting machines excel. These machines can precisely cut colored glass sheets used in architectural decoration, automotive glass, and artistic glass products. Their customizable options, including adjustable table sizes, laser power up to 500W, and special cutting heads for curved or micro-cutting, provide the flexibility needed to handle various thicknesses and colors of glass efficiently.

CKD laser glass cutting machines are also widely used in the production of decorative glass, such as glass panels for furniture, interior design, and lighting fixtures. The compatibility with popular CAD/CAM software like AutoCAD, SolidWorks, and CorelDRAW ensures that designers and manufacturers can easily integrate their designs into the cutting process with a user-friendly interface and broad programming support.

In addition, these machines are suited for precision cutting tasks in the electronics and semiconductor industries, where glass substrates require flawless edges and tight tolerances. The working voltage of 220V and an acceleration rate of 1G contribute to stable and efficient machine operation, ensuring consistent output quality.

Thanks to the wooden vacuum packaging and a delivery time of 25-45 days, CKD guarantees safe and timely shipment of each unit. With a supply ability of 60 sets per month and flexible payment terms including L/C and T/T, customers can rely on CKD for scalable production needs. The minimum order quantity of just one unit also allows for easy procurement, whether for small workshops or large manufacturing facilities.

In summary, CKD’s optical glass laser cutting machines and colored glass cutting machines are versatile solutions designed to meet the demands of industries requiring precision, customization, and reliability in glass cutting. Whether for intricate optical glass components or decorative colored glass products, these machines provide cutting-edge technology and adaptability to a wide range of application occasions and scenarios.

Customization:

CKD offers customizable Laser Glass Cutting Machines tailored to meet the diverse needs of multiple industries. Our product line includes models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-SP6070S-50E, CKD-SP6070S-60E, and CKD-SP6070C-80E, among others, all manufactured in China and certified with ISO and CE standards.

Our Glass Cutting And Splitting Machine (All-in-One) is designed as a Single Table Glass Cutting Machine, perfect for precision cutting tasks. It supports working voltages of 220V and features an acceleration of 1G with an impulse frequency ranging from 1 to 100 kHz, ensuring efficient and accurate operation.

Whether you require a Single Table Glass Cutting Machine or a Thick Glass Laser Cutting Machine, CKD provides solutions suitable for industries such as glassware (including optical glass, K9 glass, and ultra-thin glass), houseware (high-borosilicate glass, quartz glass, sanitary ware glass), vehicle (automotive glass and car windshields), new energy (photovoltaic glass), home appliance (home appliance glass and panel lighting glass), and real estate (architectural decoration and bathroom glass).

We accept a minimum order quantity of one unit, with pricing negotiable to fit your budget and project needs. Each machine is carefully packed using wooden vacuum packaging to ensure safe delivery within 25-45 days. Payment terms include L/C and T/T, and we maintain a supply ability of 60 sets per month to meet demand promptly.

Customize your laser glass cutting solution with CKD, where advanced technology meets versatile applications, delivering superior performance in both single table glass cutting machines and thick glass laser cutting machines.

Support and Services:

Our Laser Glass Cutting Machine is designed to provide precise and efficient cutting solutions for various types of glass materials. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services.

Technical Support:

Our team of experienced technicians is available to assist you with installation, setup, and troubleshooting. We provide detailed user manuals and online resources to help you understand the operation and maintenance of your laser glass cutting machine. For any technical issues, our support staff can guide you through diagnostics and repair procedures to minimize downtime.

Maintenance Services:

Regular maintenance is crucial for the consistent performance of the laser glass cutting machine. We offer scheduled maintenance services that include cleaning, calibration, and inspection of critical components to prevent unexpected failures. Our maintenance packages are designed to suit different operational needs and budgets.

Training and Consultation:

To maximize the capabilities of your laser glass cutting machine, we provide training sessions for operators and technicians. These sessions cover machine operation, safety protocols, and advanced cutting techniques. Additionally, our experts are available for consultation to help you integrate the machine into your production workflow effectively.

Spare Parts and Upgrades:

We supply genuine spare parts and accessories to ensure compatibility and reliability. Our upgrade services allow you to enhance the machine’s features and performance as new technologies become available.

Warranty and Repair:

The laser glass cutting machine comes with a standard warranty covering manufacturing defects. In case of malfunction, our repair services aim to restore your machine promptly using original parts and skilled workmanship.

Customer Satisfaction:

We are committed to providing excellent customer service and support. Your feedback is valuable to us, and we strive to continuously improve our products and services to meet your needs.