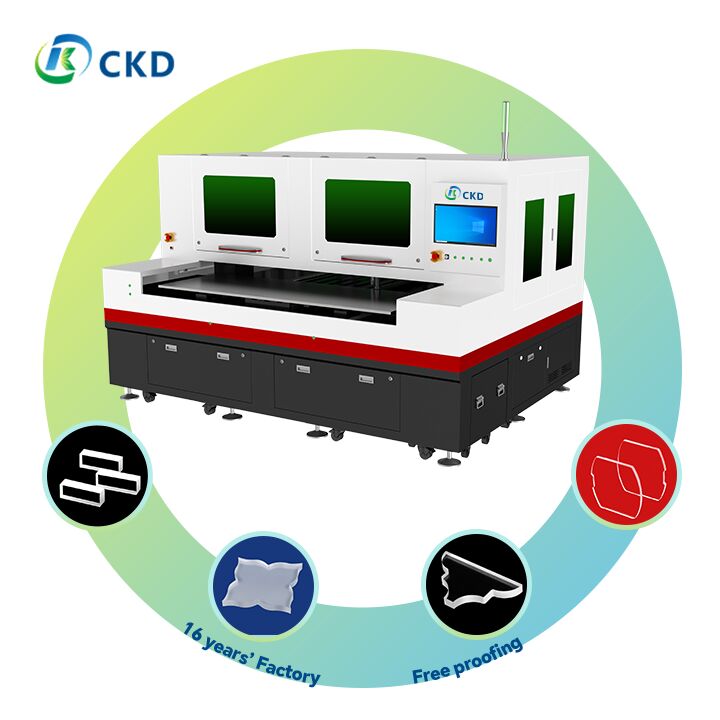

State-of-the-art Laser Glass Cutting Machine for Superior Glass Cutting Performance To Chipping ≤5μm

-

Minimum Cutting Burr≤5μm

-

Voltage , Powe<8KW , AC220V

-

Cutting Precision±0.01mm

-

Repeatability±1.5μm

-

Working Frequency50HZ/60HZ

-

Cutting SpeedAdjustable From 0-500mm/s

-

Dimension2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm

-

Linear SpeedUp To 1000mm/s

-

Max Cutting Thickness25mm

-

Cooling SystemWater Cooling

-

Accuracy±0.05mm

-

Beam QualityM^2 < 1.2

-

Impulse Frequency1-100khz

-

SoftwareLaserCut

-

Power SupplyAC 220V/380V, 50/60Hz

-

Worktable Size1300mm X 2500mm

-

Cooling MethodWater Cooling

-

Supported File FormatsPLT, DXF, BMP, AI, DST

-

Cutting Width0.03-25mm

-

Applied RangeGlass

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

State-of-the-art Laser Glass Cutting Machine for Superior Glass Cutting Performance To Chipping ≤5μm

Product Description:

The Laser Glass Cutting Machine is a state-of-the-art optical glass Laser Cutting Machine designed to meet the demanding needs of modern glass processing industries. This advanced Fiber Laser Cutting Machine offers exceptional precision and efficiency, making it an ideal solution for irregular glass cutting applications. With its cutting-edge technology, the machine ensures superior cutting quality, minimal waste, and enhanced productivity.

One of the standout features of this Laser Glass Cutting Machine is its ability to achieve a minimum cutting burr of ≤5μm. This ultra-fine precision guarantees smooth edges and reduces the need for secondary finishing processes, saving both time and costs. The machine supports a wide range of image and text formats, including AI, PLT, DXF, BMP, Dst, DWg, LAS, and DXP, providing great flexibility to accommodate various design requirements and streamline production workflows.

Designed for high-speed cutting, the Fiber Laser Cutting Machine offers an adjustable cutting speed ranging from 0 to 500mm/s. This adjustable speed allows operators to optimize the cutting process for different glass thicknesses and complexities, ensuring consistent high-quality results. Operating at a working frequency of 50HZ/60HZ, this machine is compatible with standard industrial power supplies, making it versatile and easy to integrate into existing production lines.

The Laser Glass Cutting Machine excels in handling irregular-shape glass cutting with remarkable precision and speed. Its advanced laser technology enables clean and accurate cuts without taper, burr, or significant chipping. This results in a high yield rate, as the machine minimizes material wastage and reduces the risk of defects. Additionally, its low consumables usage and energy-saving design contribute to cost efficiency and environmental sustainability.

Environmental considerations are integral to the design of this Fiber Laser Cutting Machine. The cutting process generates no pollution, no powder, and no wastewater, making it an eco-friendly choice for glass manufacturers. This feature not only benefits the environment but also ensures a safer and cleaner working environment for operators.

In summary, the optical glass Laser Cutting Machine offers a comprehensive solution for precise, efficient, and sustainable glass cutting. Its ability to handle irregular glass cutting with high cutting quality, combined with its energy-saving and low-maintenance features, makes it a valuable asset for industries requiring advanced glass processing. Whether for intricate designs or large-scale production, this Fiber Laser Cutting Machine delivers outstanding performance, reliability, and cost-effectiveness.

Features:

- Product Name: Laser Glass Cutting Machine

- Model: Glass Cutting And Splitting Machine (All-in-One)

- Positioning Accuracy: ±2μm for high precision cutting

- Cutting Thickness: Ultra-clear glass single cut up to 19mm, blue glass double cut up to 19mm

- Splitting Laser Source: RFC02 (Radio Frequency CO2) - 10.6μm wavelength, 150W power (optional 250W/350W), 1-100kHz frequency with water cooling system

- Energy Consumption: Standby power approximately 500W; average power consumption during cutting is 2.5kW, featuring energy-efficient and eco-friendly modes

- Environmentally friendly design making it an ideal environmental protection glass laser cutting machine

- High Precision Laser Cutting Machine suitable for detailed and accurate glass processing

- Also functions as a stained glass cutting machine for specialized glass art and applications

Applications:

The CKD Laser Glass Cutting Machine series, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, and CKD-SP6070C-50E among others, is designed to meet a wide range of industrial and artistic glass cutting needs. Originating from China and certified with ISO and CE standards, these machines provide reliable, high-precision cutting solutions for various glass types including ultra-clear optical glass and stained glass.

One of the primary application occasions for the CKD optical glass laser cutting machine is in precision manufacturing environments where ultra-clear glass cutting is critical. With a maximum cutting thickness of up to 19mm for single cuts on ultra-clear glass and double cuts on blue glass, these machines excel in producing flawless edges with minimal burrs (≤5μm), making them ideal for optical instrument components, high-end glass panels, and specialty glass products.

In addition to industrial use, the CKD small glass laser cutting machine models are perfectly suited for artisanal and small-batch production scenarios. These machines provide exceptional flexibility and accuracy, enabling designers and craftsmen to cut intricate patterns on stained glass for decorative windows, custom glass art, and architectural glass installations. The rack and pinion transmission system ensures smooth and precise movement, contributing to superior cut quality and repeatability.

The versatility of the CKD stained glass cutting machine also extends to educational and research institutions that require precise glass sample preparation. With a working environment optimized at 26℃ and a robust machine weight of 3500kg ensuring stability, these machines deliver consistent performance and durability. The wooden vacuum packaging guarantees safe delivery within 25-45 days, with flexible payment terms including L/C and T/T to accommodate various buyers.

Whether for large-scale manufacturing or specialized artistic projects, the CKD Laser Glass Cutting Machines offer unmatched performance, reliability, and precision. Their ability to handle various glass types, combined with advanced transmission and cutting technology, makes them indispensable tools in glass processing workshops, optical component factories, and stained glass studios worldwide.

Customization:

CKD offers customized Glass Cutting And Splitting Machines (All-in-One) with model numbers including CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E.

Originating from China, these thick glass laser cutting machines are certified with ISO and CE standards, ensuring high quality and reliability for all your glass processing needs.

Our environmental protection glass laser cutting machines feature a pulse width of less than 10ps and an acceleration of 1G, providing precise and efficient laser cutting performance. The operating noise level is maintained at 70dB with a built-in silencing system, making it suitable for low-noise environments.

We specialize in irregular glass cutting solutions tailored to your specifications, with a minimum order quantity of just 1 unit. Pricing is negotiated to meet your project requirements, and each machine is securely packaged using wooden vacuum packaging for safe delivery.

Delivery time ranges from 25 to 45 days, supported by flexible payment terms including L/C and T/T. Our supply ability is up to 60 sets per month, allowing us to meet both small and large orders efficiently.

Choose CKD's Glass Cutting And Splitting Machine for advanced thick glass laser cutting, exceptional irregular glass cutting capabilities, and commitment to environmental protection in every laser cutting machine we deliver.

Support and Services:

Our Laser Glass Cutting Machine is designed to provide precise and efficient cutting solutions for various types of glass. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services.

Technical Support:

Our expert technical support team is available to assist you with installation, setup, and troubleshooting. We provide detailed user manuals and online resources to help you understand the operation and maintenance of the machine. Should you encounter any issues, our technicians are ready to guide you through step-by-step solutions.

Maintenance Services:

Regular maintenance is crucial for the best performance of your Laser Glass Cutting Machine. We offer scheduled maintenance services, including calibration, cleaning, and part replacement, to prevent downtime and extend the lifespan of your equipment.

Training:

We provide comprehensive training sessions for your operators to ensure safe and effective use of the machine. Training covers machine operation, safety protocols, and basic troubleshooting techniques.

Software Updates:

Our machines come with advanced software that is regularly updated to enhance functionality and security. We provide free software updates and technical guidance to keep your system up-to-date.

Warranty and Repairs:

The Laser Glass Cutting Machine includes a warranty covering manufacturing defects. In the event of a malfunction, our service centers are equipped to perform repairs efficiently, minimizing your downtime.

Spare Parts:

We maintain an inventory of genuine spare parts to ensure quick replacement and maintain the machine’s performance and safety standards.

For further assistance, please refer to the user manual or visit our support website for FAQs and troubleshooting guides.