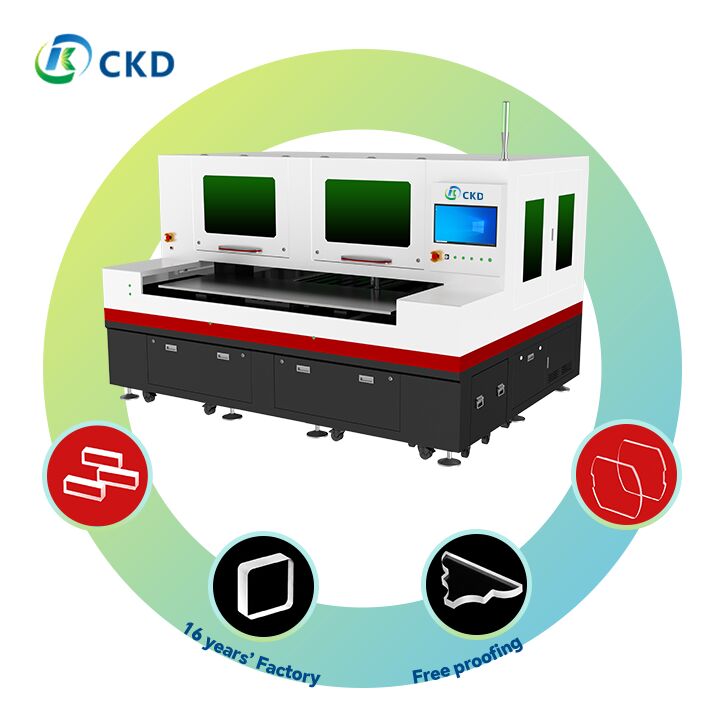

Customizable Laser Glass Cutting Machine for Unique Glass Cutting Needs To Speed 0-500mm/s

-

Cutting Accuracy±0.01mm

-

Acceleration1G

-

MobilityEquipped With Heavy-duty Wheels For Easy Movement And Repositioning, With Locking Mechanisms For Stability

-

Safety FeaturesIncludes Emergency Stop Button, Protective Cover, Laser Safety Windows, And Automatic Power-off When The Cover Is Open For Safe Operation.

-

Pulse Frequency1Hz - 1000kHz

-

Key Selling PointsUltra Fast Picesecond

-

Cutting ThicknessUltra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm

-

Linear SpeedUp To 1000mm/s

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Customizable Laser Glass Cutting Machine for Unique Glass Cutting Needs To Speed 0-500mm/s

Product Description:

The Laser Glass Cutting Machine is a state-of-the-art Single Table Glass Cutting Machine designed to meet the evolving needs of the glass processing industry. This advanced equipment delivers unparalleled precision and efficiency, making it ideal for cutting a wide variety of glass types, including irregular glass shapes that require meticulous handling and accuracy. Equipped with cutting-edge technology, this machine ensures superior performance in both industrial and commercial applications.

One of the standout features of this Laser Glass Cutting Machine is its ultra-fast picosecond pulse laser technology, which operates at an impulse frequency ranging from 1 to 100 kHz. This high-frequency pulse capability allows for extremely fine and precise cuts, reducing thermal damage and minimizing edge chipping on delicate glass surfaces. The picosecond laser pulses enable rapid material processing with exceptional quality, resulting in clean cuts that maintain the structural integrity of the glass.

The machine utilizes a splitting laser source with a wavelength of 10.6 µm, specifically optimized for glass cutting applications. This wavelength is highly effective in absorbing the laser energy and achieving smooth, consistent cuts across various glass thicknesses. The precision of the laser source, combined with the ultra-fast pulse frequency, ensures that even the most intricate and irregular glass cutting tasks can be performed with ease and accuracy.

To guarantee smooth and stable operation, the Laser Glass Cutting Machine is equipped with premium linear guides from the renowned brand TPI. These linear guides provide excellent rigidity and precision in movement, allowing the cutting head to follow complex contours and patterns without deviation. The robust construction and high-quality components contribute to the machine’s longevity and reliability, making it a valuable investment for any glass processing facility.

In addition to its technical capabilities, the machine is designed with full compatibility for integration with major automation systems. It supports seamless interfacing with robot systems and automatic loading and unloading devices, significantly enhancing production line efficiency and reducing manual labor requirements. The standard industrial communication protocols, including Modbus and OPC, are supported to ensure smooth data exchange and control within automated workflows.

This Fiber Laser Cutting Machine variant emphasizes versatility and adaptability, making it suitable for a wide range of applications beyond traditional glass cutting. Its ability to handle irregular glass cutting tasks with high precision opens new possibilities for custom glass products, architectural glass components, and specialty glass manufacturing. The combination of fiber laser technology and advanced automation compatibility positions this machine as a leader in modern glass processing solutions.

In summary, the Laser Glass Cutting Machine offers an exceptional blend of ultra-fast picosecond laser cutting, high-frequency impulse control, and superior mechanical precision thanks to TPI linear guides. Its compatibility with automation systems and support for standard industrial communication protocols make it an ideal choice for companies looking to enhance productivity and maintain high-quality standards in glass cutting operations. Whether you need a reliable Single Table Glass Cutting Machine for regular production or a flexible solution for irregular glass cutting challenges, this Fiber Laser Cutting Machine provides the performance and integration capabilities to meet your demands.

Features:

- Product Name: Laser Glass Cutting Machine

- Brand: CKD

- Impulse Frequency: 1-100 kHz

- Laser Wavelength: 1064 nm

- Cutting Area Options: 400mm x 500mm, 600mm x 700mm, 600mm x 900mm

- Environmental Conditions: Works best in temperatures between 15°C and 30°C, with 20%-80% relative humidity

- Suitable for cleanrooms or industrial environments

- Ideal for Single Table Glass Cutting Machine applications

- Efficient single table glass cutting machine design for precision and speed

- Perfect for colored glass cutting machine requirements

Applications:

The CKD brand offers an advanced range of Laser Glass Cutting Machines, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, and many others, all originating from China and certified with ISO and CE standards. These machines are designed for high precision and efficiency, making them ideal for various industrial and commercial applications. The thick glass laser cutting machine models within this lineup are especially suited for industries requiring reliable and clean cuts on thick glass materials, ensuring minimal waste and superior edge quality.

One of the key application occasions for the CKD laser glass cutting machines is in the manufacturing sector, where thick glass components are essential. These machines excel in cutting automotive glass, architectural glass panels, and specialty glass used in electronic devices. The Fiber Laser Cutting Machine variants offer versatility and high-speed linear cutting capabilities, reaching up to 1000mm/s, which significantly boosts productivity in mass production environments. Their infrared picosecond laser type and pulse width of less than 10ps enable ultra-fine and precise cuts, catering to industries demanding high accuracy.

In the construction industry, the thick glass laser cutting machine proves indispensable for producing custom-sized glass panels for windows, doors, and facades. The ability to handle various thicknesses with pulse frequencies ranging from 1Hz to 1000kHz and the option of different power settings (150W, 250W, 350W) allows customization for specific project requirements. These machines are also widely used in the production of decorative glass items, where intricate patterns and shapes are needed without compromising the integrity of the glass.

Moreover, the CKD laser glass cutting machines are highly applicable in the electronics and telecommunications industries. Their precision cutting ensures that glass screens and covers for smartphones, tablets, and other devices meet stringent quality standards. The inclusion of water cooling systems and RFC02 Radio Frequency CO2 laser sources enhances performance and durability, making these machines reliable for continuous operation.

With a minimum order quantity of just one set, wooden vacuum packaging for secure delivery, and a supply ability of 60 sets per month, CKD’s laser glass cutting machines are accessible to both small businesses and large manufacturers. The delivery time ranges between 25 to 45 days, with flexible payment terms including L/C and T/T. Whether for thick glass laser cutting machine needs or fiber laser cutting machine applications, CKD’s comprehensive product line ensures that customers receive cutting-edge technology tailored for their specific cutting and processing scenarios.

Customization:

CKD offers customizable Laser Glass Cutting Machines designed to meet your specific needs. Our product range includes multiple models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, and CKD-SP6070C-80E, ensuring a tailored fit for various glass cutting applications.

Originating from China, our machines are certified with ISO and CE standards, guaranteeing high quality and reliability. We accept minimum order quantities of 1 unit, with pricing available on negotiation to best suit your budget and requirements.

Each Laser Glass Cutting Machine is packaged securely using wooden vacuum packaging to ensure safe delivery. The delivery time ranges between 25 to 45 days, with flexible payment terms including L/C and T/T.

Our supply ability is 60 sets per month, supported by premium TPI linear guides, which contribute to exceptional precision with chipping less than or equal to 5μm. The machines feature a linear speed of up to 1000mm/s and cutting thickness capabilities ranging from 0.03mm to 25mm.

The cutting speed is fully adjustable from 0 to 500mm/s, allowing for precise control depending on the type of glass and cutting requirements. Our Laser Glass Cutting Machines are ideal for applications involving colored glass cutting machine operations, optical glass laser cutting machine tasks, and thick glass laser cutting machine processes.

Choose CKD for advanced, customizable glass cutting solutions that combine quality, efficiency, and versatility to meet your industrial needs.

Support and Services:

Our Laser Glass Cutting Machine is designed to provide precision and efficiency for all your glass cutting needs. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services.

Technical Support:

Our expert technical support team is available to assist you with installation, setup, and troubleshooting. We provide detailed user manuals and online resources to help you understand the operation and maintenance of your laser glass cutting machine. Should you encounter any issues, our support staff can guide you through diagnostic procedures and recommend solutions.

Maintenance Services:

Regular maintenance is crucial for the smooth functioning of your laser glass cutting machine. We offer scheduled maintenance services including calibration, cleaning, and parts inspection to prevent unexpected downtime and extend the life of your equipment.

Training and Consultation:

We provide training sessions for operators to ensure safe and effective use of the machine. Our consultants can also assist in optimizing your cutting processes and integrating the machine into your production line for maximum productivity.

Spare Parts and Upgrades:

Access to genuine spare parts and upgrade options is available to keep your machine running at peak performance. We recommend using only authorized parts to maintain safety and warranty coverage.

Warranty and Repairs:

Our Laser Glass Cutting Machine comes with a standard warranty covering manufacturing defects. In the event of a malfunction, our repair service ensures timely and efficient restoration of your equipment to minimize downtime.

Customer Satisfaction:

We are committed to providing excellent customer service and support to help you achieve the best results with your laser glass cutting machine. Your satisfaction is our priority.