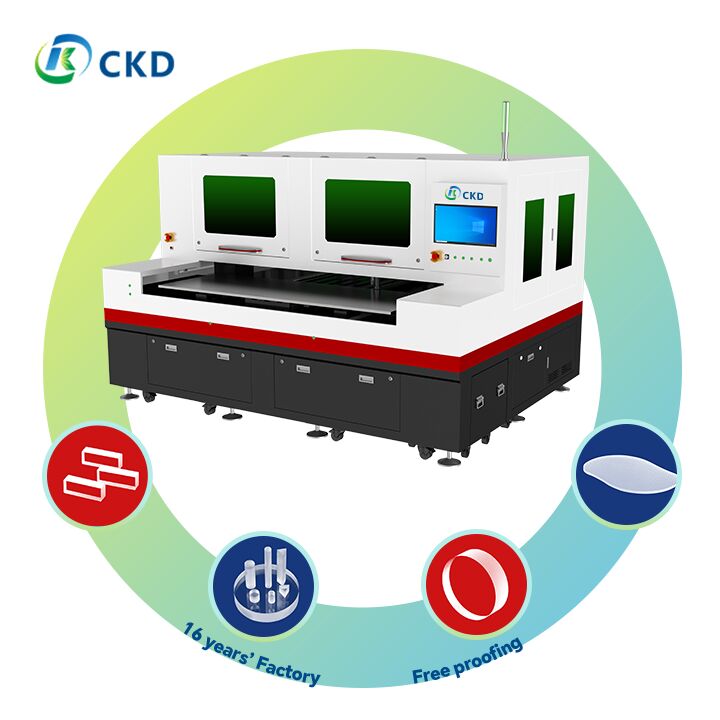

Splitting laser source Wavelength 10.6µm Panel Lighting Glass Real Estate Environmental protection glass laser cutting machine

-

Voltage , Powe<8KW , AC220V

-

Beam QualityM² < 1.2

-

Support Image And Text FormatsAI PLT DXF BMP Dst DWg LAS DXP

-

Cutting Width0.03-25mm

-

Work Size610*700mm X 2 Customizable

-

NameGlass Cutting And Splitting Machine (All-in-One)

-

Applicable IndustriesGlassware Industry: Optical Glass, K9 Glass, And Ultra-thin Glass Houseware Industry: High-borosilicate Glass, Quartz Glass, Sanitary Ware Glass Vehicle Industry: Automotive Glass, Car Windshield, Etc. New Energy: Photovoltaic Glass Home Appliance: Home Ap

-

Control SystemCNC

-

MaterialCamera Sapphire Glass Cover

-

Wavelength1064nm

-

Pulse Frequency1Hz - 1000kHz

-

Chipping≤5μm

-

Positioning Accuracy±0.03mm

-

Key Selling PointsUltra Fast Picesecond

-

Graphic FormatPLT/DXF/BMP/JPG/GIF/PNG/TIF

-

Working Frequency50HZ/60HZ

-

Operating EnvironmentAround 26 Degrees Celsius

-

Working TableHoneycomb/Aluminum Blade

-

Laser Source BrandRAYCUS

-

Linear SpeedUp To 1000mm/s

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Splitting laser source Wavelength 10.6µm Panel Lighting Glass Real Estate Environmental protection glass laser cutting machine

Product Description:

The Laser Glass Cutting Machine is a state-of-the-art solution designed to meet the precise demands of modern glass processing industries. Engineered for exceptional performance, this optical glass Laser Cutting Machine offers unparalleled cutting accuracy with a tolerance of ±0.01mm, ensuring flawless edges and intricate designs every time. Whether you are working with delicate optical glass or robust colored glass, this machine delivers consistent, high-quality results that meet the highest standards.

One of the standout features of this laser cutting machine is its impressive linear speed, capable of reaching up to 1000mm/s. This high-speed operation significantly enhances productivity, allowing manufacturers to process large volumes of glass efficiently without compromising on precision. The rapid movement combined with precise control makes it an ideal choice for industries requiring both speed and accuracy, such as electronics, automotive, and decorative glass manufacturing.

The versatility of this laser cutter is further highlighted by its ability to handle a wide range of cutting widths, from as narrow as 0.03mm to as wide as 25mm. This flexibility enables users to work on various glass types and thicknesses with ease. Whether you need to cut ultra-thin sheets of colored glass or thicker panels with complex patterns, this machine adapts seamlessly to your requirements, making it a comprehensive solution for diverse glass cutting tasks.

Designed to operate efficiently under different electrical standards, the machine supports a working frequency of both 50HZ and 60HZ. This adaptability ensures stable performance across various regions and industrial environments, providing reliable operation no matter where it is installed. The consistent working frequency also contributes to the machine’s precision and durability, reducing the likelihood of errors or downtime during production.

At the heart of this laser cutting system is a robust rack and pinion transmission system that guarantees smooth and accurate movement of the cutting head. This mechanical design is known for its reliability and minimal maintenance requirements, which translates to lower operational costs and increased machine uptime. The rack and pinion system ensures that every cut is executed with exact positioning, further enhancing the overall cutting accuracy of the machine.

This Thick glass laser cutting machine is specifically engineered to handle the challenges associated with cutting heavier and denser glass materials. The powerful laser, combined with advanced control systems, ensures clean and precise cuts even on thicker glass panels that are difficult to process using conventional methods. This capability opens up new possibilities for manufacturers working with architectural glass, automotive windshields, and other specialized applications where thickness and strength are critical.

In addition to its technical specifications, the optical glass Laser Cutting Machine is designed for user-friendly operation and integration into existing production lines. Its intuitive interface and automated features minimize the learning curve, allowing operators to quickly master the system and maintain high levels of efficiency. The machine’s compact footprint and modular design also make it easy to install and customize according to specific production needs.

Overall, this colored glass cutting machine represents a perfect blend of precision, speed, and versatility. Its advanced features make it an indispensable tool for industries requiring intricate glass cutting with minimal waste and maximum quality. Whether your focus is on delicate optical components, vibrant colored glass products, or heavy-duty thick glass applications, this laser cutting machine delivers exceptional performance tailored to your needs.

Choose this Laser Glass Cutting Machine to elevate your glass processing capabilities with cutting-edge technology that guarantees accuracy, efficiency, and reliability. Experience the benefits of superior cutting quality and enhanced productivity while reducing material loss and operational costs, making it a smart investment for any glass manufacturing business.

Features:

- Product Name: Laser Glass Cutting Machine

- High cutting precision of ±0.01mm for accurate results

- Low power consumption: <8KW, operates on AC220V

- Ultra-short pulse width of less than 10ps for precise cutting

- Operating noise level is 70dB, equipped with a built-in silencing system, making it suitable for low-noise environments

- Capable of cutting glass thickness ranging from 0.03mm to 25mm

- Versatile usage as a colored glass cutting machine, stained glass cutting machine, and optical glass laser cutting machine

Applications:

The CKD Laser Glass Cutting Machine series, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070D-50E, and CKD-SP6070C-80E, is designed for precision and efficiency in glass cutting applications. Originating from China and certified with ISO and CE, these machines are ideal for a variety of cutting needs, including optical glass laser cutting machine applications, stained glass cutting machine tasks, and thick glass laser cutting machine operations. With customizable work sizes of 610*700mm X 2 and a cutting thickness range from 0.03mm to 25mm, the CKD series caters to diverse industrial and artistic glass processing requirements.

In manufacturing environments where precision and repeatability are crucial, the CKD laser glass cutting machines excel. Their rack and pinion transmission system ensures smooth and accurate movement, while the RFC02 Radio Frequency CO2 laser source (with power options of 150W, 250W, and 350W) provides reliable and high-quality cutting performance. These machines are particularly suited for producing intricate optical glass components used in electronics, medical devices, and scientific instruments, where clean and precise cuts are paramount.

For stained glass artisans and manufacturers, the CKD stained glass cutting machine models offer unparalleled accuracy and the ability to handle delicate, colorful glass sheets without cracking or damaging the material. The laser technology enables detailed designs and complex shapes to be cut efficiently, supporting creative freedom and high production throughput. The water-cooled laser source ensures consistent operation during long cutting sessions, making it ideal for both small workshops and larger stained glass production facilities.

The thick glass laser cutting machine capability within the CKD range addresses the needs of industries requiring the processing of robust glass panels up to 25mm thick. This includes architectural glass cutting, automotive glass manufacturing, and specialized glass products such as bulletproof or tempered glass. The machine’s compatibility with major automation systems, including robot interfaces and automatic loading/unloading systems, streamlines production lines, reduces labor costs, and enhances safety.

CKD’s laser glass cutting machines are packaged securely with wooden vacuum packaging to ensure safe delivery within 25-45 days, with flexible payment terms including L/C and T/T. With a supply ability of 60 sets per month and negotiable pricing, customers can rely on CKD for timely and cost-effective solutions. The standard industrial communication protocols like Modbus and OPC enable seamless integration into existing manufacturing systems, making CKD laser glass cutting machines a versatile choice for modern glass processing enterprises.

Customization:

CKD offers a range of high precision laser cutting machines, including the Fiber Laser Cutting Machine and Stained Glass Cutting Machine, designed to meet diverse cutting needs. Our Laser Glass Cutting Machine models include CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E.

Manufactured in China, these machines are certified with ISO and CE standards, ensuring high quality and reliability. We offer a minimum order quantity of one unit, with prices negotiable to suit your specific requirements.

Each Laser Glass Cutting Machine is packaged with wooden vacuum packaging to guarantee safe delivery. Our delivery time ranges from 25 to 45 days, supported by a supply ability of 60 sets per month.

Key technical specifications include a chipping size of ≤5μm, linear speed up to 1000mm/s, and a splitting laser source with a water cooling method. The machines operate at a voltage and power of less than 8KW, AC220V, and are equipped with an efficient water cooling system.

Payment terms are flexible, accepting L/C and T/T methods. CKD’s high precision laser cutting machines are ideal for applications requiring precision and speed, especially in fiber laser cutting and stained glass cutting projects. Customize your Laser Glass Cutting Machine with CKD to achieve superior cutting performance and reliability.

Support and Services:

Our Laser Glass Cutting Machine is designed to deliver precision and efficiency for all your glass processing needs. To ensure optimal performance and longevity of your equipment, please follow the guidelines below.

Technical Support:

Our technical support team is dedicated to assisting you with installation, operation, and troubleshooting. Comprehensive user manuals and instructional videos are available to guide you through the setup and maintenance processes. For any technical issues, please ensure you have the machine model and serial number ready to facilitate prompt assistance.

Maintenance Services:

Regular maintenance is crucial for the sustained accuracy and efficiency of your laser glass cutting machine. We recommend routine cleaning of the laser lens, checking alignment, and inspecting electrical connections. Scheduled maintenance services can be arranged to be performed by certified technicians to keep your machine in peak condition.

Training and Consultation:

We offer training programs for operators to maximize the capabilities of the laser glass cutting machine safely and effectively. Additionally, consultation services are available to help optimize your cutting processes and integrate the machine seamlessly into your production line.

Warranty and Repairs:

The machine comes with a standard warranty covering manufacturing defects and workmanship. In case of malfunction, authorized repair services are provided to minimize downtime. Please ensure that all repairs are carried out by qualified personnel to maintain warranty validity.

Software Updates:

Periodic software updates are released to enhance functionality and add new features. Customers are encouraged to keep their machine’s software up to date by downloading updates from our official platform.

For further assistance and detailed service options, please refer to the product documentation provided with your Laser Glass Cutting Machine.