Upgrade Your Glass Cutting Process with Our Advanced Laser Glass Cutting Machine To Accuracy±0.01mm

-

Laser Wavelength1064nm

-

Working Environment26℃

-

Applicable MaterialsUltra Clear Class, Plain White Glass High Borosilicate Glass, Quartz Glass Optical Glass, Cover Glass, Camera Glass Cover, Etc. Phone Glass Cover, Car Glass, Camera Glass Cover, Etc. LCD Screen, K9 Glass, Filter Cutting, Mirror Cutting, Etc.

-

Minimum Cutting Burr≤5um

-

Cutting ThicknessUltra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm

-

Cutting Accuracy±0.01mm

-

Transmission SystemRack And Pinion

-

Pulse Width<10ps

-

Cutting Width0.03-25mm

-

Key Selling PointsAutomatic

-

Service LifeLong Life

-

Machinery Efficiency0-500mm/s

-

Applied RangeGlass

-

Glass ThicknessLess Than 25mm

-

Laser80W

-

AdvantagesSmall Chipping

-

Drive MotorXY Linear Motor + Optical Grating Scale

-

SoftwareLaserCut

-

Acceleration1G

-

Repeatability±1.5um

-

Linear SpeedUp To 1000mm/s

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

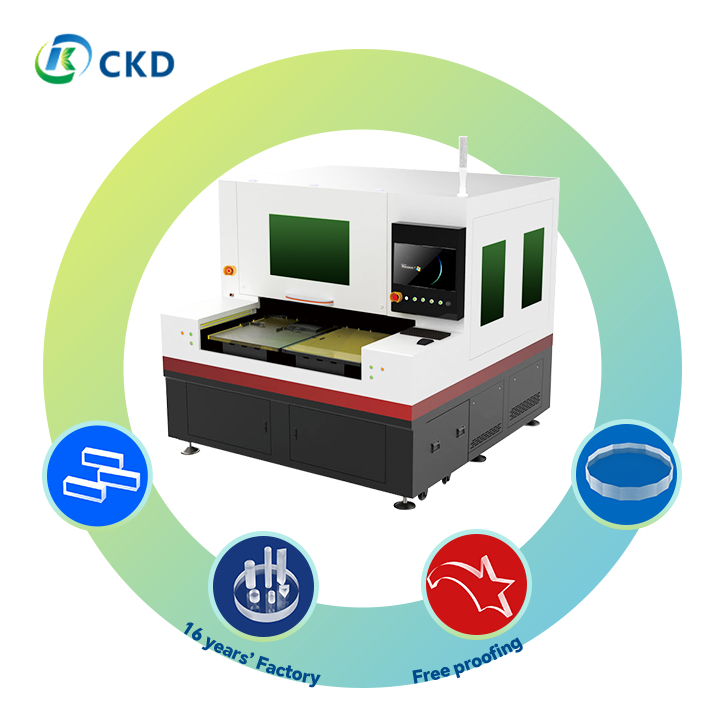

Upgrade Your Glass Cutting Process with Our Advanced Laser Glass Cutting Machine To Accuracy±0.01mm

Product Description:

The Laser Glass Cutting Machine is an advanced and highly efficient tool designed to meet the precise demands of modern glass processing industries. This Fiber Laser Cutting Machine is specifically engineered to handle various types of glass materials, including colored glass and optical glass, delivering exceptional cutting quality and accuracy. With its cutting-edge technology and robust construction, it is the ideal solution for businesses seeking precision and reliability in glass cutting applications.

One of the standout features of this Laser Glass Cutting Machine is its working frequency, which can be set to 50HZ or 60HZ, ensuring compatibility with different regional power standards and optimizing performance according to specific operational requirements. This flexibility allows users to maintain consistent cutting quality regardless of location, making it an excellent choice for international operations or multi-site manufacturing facilities.

The machine offers a versatile cutting width range from as narrow as 0.03mm up to 25mm, enabling it to handle a wide variety of glass thicknesses and cutting designs. Whether you are working with delicate optical glass requiring precision cuts or thicker colored glass materials that demand robust cutting power, this machine can adapt effortlessly to your needs. This broad cutting width capability ensures that the Laser Glass Cutting Machine can be used in diverse applications, from intricate decorative glasswork to industrial-grade cutting tasks.

Designed with a generous work size of 610mm by 700mm per unit and featuring dual units (X 2), the machine provides ample workspace to accommodate larger glass sheets or simultaneous processing of multiple pieces. Furthermore, the work size is customizable, allowing users to tailor the machine dimensions to specific project requirements or production line constraints. This customization feature enhances operational efficiency and maximizes material utilization, reducing waste and increasing productivity.

As a CNC-enabled device, the Laser Glass Cutting Machine delivers automated, computer-controlled precision cutting. This CNC capability ensures consistent results, reduces human error, and allows for complex cutting patterns that are difficult or impossible to achieve manually. The integration of CNC technology is particularly beneficial for producing high-quality optical glass components where exact specifications and repeatability are critical.

The machine also comes with a comprehensive 2-year warranty that covers major components such as the laser source and control system. This warranty reflects the manufacturer’s confidence in the product’s durability and performance reliability. Additionally, customers receive 24/7 technical support, which includes both remote assistance and on-site service options. This ensures that any operational issues can be swiftly resolved, minimizing downtime and maintaining continuous production flow.

Specialized as a colored glass cutting machine and an optical glass Laser Cutting Machine, this equipment is uniquely suited to industries that require precision cutting of high-quality glass materials. Whether used for decorative architectural glass, automotive glass, or optical instrument components, the Laser Glass Cutting Machine provides superior performance and exceptional cutting precision.

In summary, the Laser Glass Cutting Machine combines advanced fiber laser technology with versatile cutting capabilities, customizable work areas, and robust CNC control. Its dual-frequency operation, extensive warranty coverage, and dedicated technical support make it a reliable and efficient solution for glass manufacturers seeking to enhance their production capabilities. This machine represents a significant investment in quality, precision, and long-term operational success in the field of glass cutting.

Features:

- Product Name: Laser Glass Cutting Machine

- Cutting Area Options: 400mm × 500mm, 600mm × 700mm, 600mm × 900mm

- High repeatability precision: ±1.5μm

- Laser Source: RFC02 (Radio Frequency CO2) splitting laser

- Drive System: XY Linear Motor combined with Grating Ruler for accurate positioning

- Machine Weight: 3500kg ensuring stability during operation

- Suitable for applications as a thick glass laser cutting machine

- Designed as a polygonal glass cutting machine for complex shapes

- Compact design qualifies it as a small glass laser cutting machine

Applications:

The CKD Laser Glass Cutting Machine series, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, and many others, represents a cutting-edge solution for precision glass cutting applications. Originating from China and certified with ISO and CE standards, this range of machines is designed to meet the diverse needs of modern glass processing industries. With a supply ability of 60 sets per month and flexible payment terms like L/C and T/T, CKD ensures reliable delivery within 25-45 days, packaged securely with wooden vacuum packaging to maintain product integrity.

This small glass laser cutting machine is ideal for environments where space efficiency and precision are paramount. Its compact dimensions, ranging from 2150mm × 2080mm × 1960mm to 2550mm × 2080mm × 1960mm, make it suitable for workshops and manufacturing plants that require high accuracy without compromising floor space. Equipped with a high-quality splitting laser source power of 150W, with optional upgrades to 250W or 350W, and an RFC02 radio frequency CO2 laser type, the machine delivers exceptional beam quality (M² < 1.2) and ultra-short pulse widths of less than 10ps, ensuring clean and precise cuts on various types of glass materials.

The single table glass cutting machine models from CKD are particularly applicable in small to medium scale glass fabrication industries, where individualized or batch processing is required. These machines excel in cutting architectural glass, automotive glass, decorative glass, and other specialty glass products with minimal thermal impact and high repeatability. Their environmental protection glass laser cutting capabilities make them an excellent choice for companies committed to sustainable manufacturing practices, as they reduce waste and minimize harmful emissions compared to traditional cutting methods.

Application occasions for CKD’s laser glass cutting machines span from industrial glass production lines to specialized custom glass workshops. They are perfect for scenarios requiring precision cutting of tempered glass, laminated glass, and ultra-thin glass sheets used in electronics, solar panels, and smart devices. Additionally, these machines are widely utilized in the production of glass components for home appliances, furniture, and decorative installations, where intricate designs and smooth edges are essential.

In summary, CKD’s laser glass cutting machines offer versatile, efficient, and eco-friendly solutions for a variety of glass cutting scenarios. Their advanced technology, including the RFC02 laser source and high beam quality, combined with robust build quality and comprehensive certifications, make them a trusted choice for businesses seeking reliable and precise glass processing equipment. Whether you require a small glass laser cutting machine for compact spaces or a single table glass cutting machine for batch processing, CKD’s range is engineered to deliver superior performance and sustainability.

Customization:

The CKD Laser Glass Cutting Machine offers extensive product customization services tailored to meet diverse industry needs. Our models, including CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E, are designed for versatility and precision.

Manufactured in China and certified with ISO and CE standards, our laser cutting machines support a minimum order quantity of just one unit, with prices negotiable to suit your budget. Each unit is securely packed using wooden vacuum packaging to ensure safe delivery within 25-45 days. Payment terms include L/C and T/T to provide flexible financial options.

With a supply ability of 60 sets per month, CKD’s Laser Glass Cutting Machines cater to a wide range of industries such as the glassware industry (optical glass, K9 glass, and ultra-thin glass), houseware industry (high-borosilicate glass, quartz glass, sanitary ware glass), vehicle industry (automotive glass, car windshield), new energy sector (photovoltaic glass), home appliance (home appliance glass, panel lighting glass), and real estate (architectural decoration, bathroom glass).

Our stained glass cutting machine models feature acceleration of 1G, dimensions of 2150mm × 2080mm × 1960mm or 2550mm × 2080mm × 1960mm, and exceptional repeatability of ±1.5μm. The environmental protection glass laser cutting machine operates at a noise level of 70dB, equipped with a built-in silencing system, making it suitable for low-noise environments.

CKD’s optical glass laser cutting machine is engineered to provide high precision and efficiency, ensuring superior performance across applications. We are committed to delivering customized solutions that align perfectly with your production requirements and industry standards.

Support and Services:

Our Laser Glass Cutting Machine comes with comprehensive technical support and services to ensure optimal performance and maximum uptime.

Installation and Setup: We provide full installation and setup assistance to get your laser glass cutting machine up and running smoothly and efficiently.

Training: Our expert technicians offer thorough training sessions for your operators to maximize their proficiency and ensure safe operation of the machine.

Maintenance Services: Regular maintenance packages are available to keep your machine in peak condition, including cleaning, calibration, and replacement of worn parts.

Troubleshooting and Repairs: Our dedicated support team is ready to assist with troubleshooting any issues and providing prompt repair services to minimize downtime.

Software Updates: Stay up to date with the latest software improvements and features through our periodic update services.

Spare Parts Supply: We maintain a stock of genuine spare parts to ensure quick replacement and sustained machine performance.

Technical Documentation: Comprehensive manuals and technical documents are provided to assist with machine operation, maintenance, and troubleshooting.

Remote Support: For immediate assistance, remote diagnostics and support options are available to quickly address technical concerns.

Customer Service: Our customer service team is committed to providing timely and effective responses to all your inquiries and support needs.