Boost Your Glass Cutting Process with Our High-Performance Laser Glass Cutting Machine To Chipping ≤5μm

-

Splitting Laser Source Wavelength10.6µm

-

NameGlass Cutting And Splitting Machine (All-in-One)

-

Minimum Cutting Burr≤5μm

-

Linear SpeedUp To 1000mm/s

-

Environmental ConditionsWorks Best In Temperatures Between 15°C And 30°C, With 20%-80% Relative Humidity, Suitable For Cleanrooms Or Industrial Environments

-

Cooling SystemWater Cooling

-

Beam QualityM² < 1.2

-

Control SoftwareCompatible With Popular CAD/CAM Software Like AutoCAD, SolidWorks, And CorelDRAW. Easy To Use Interface With Broad Programming Support.

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Boost Your Glass Cutting Process with Our High-Performance Laser Glass Cutting Machine To Chipping ≤5μm

Product Description:

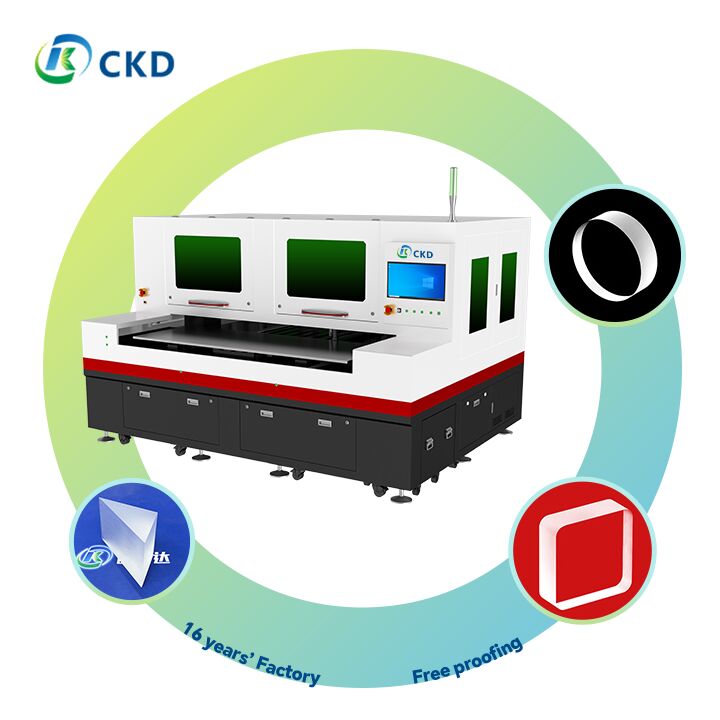

The Laser Glass Cutting Machine is a state-of-the-art thick glass laser cutting machine designed to deliver unparalleled precision and efficiency in glass processing. Equipped with a powerful splitting laser source of 150W, with optional upgrades to 250W or 350W, this high precision laser cutting machine is engineered to handle a variety of glass cutting tasks, including stained glass cutting, with exceptional speed and accuracy. Its advanced laser technology ensures superior cutting quality, enabling users to achieve intricate and irregular shapes without compromising on the integrity of the glass.

One of the standout advantages of this laser glass cutting machine is its ability to perform high-speed cutting while maintaining outstanding precision. The cutting process produces no taper and no burr, resulting in clean and smooth edges that require minimal post-processing. Additionally, the machine minimizes chipping, which significantly increases the yield rate of glass products. This efficiency not only improves productivity but also reduces material wastage, making it an economical choice for manufacturers and artisans alike.

Energy efficiency and environmental consideration are integral to the design of this machine. It operates with low consumable usage and energy-saving features, ensuring that operational costs remain low without compromising performance. The cutting process is environmentally friendly, producing no pollution, no powder, and no wastewater, which aligns with modern sustainability standards and helps maintain a clean working environment.

To ensure reliability and peace of mind, the Laser Glass Cutting Machine comes with a comprehensive 2-year warranty covering major components such as the laser source and the control system. Customers benefit from 24/7 technical support, with both remote assistance and on-site service options available. This commitment to service guarantees that any issues can be promptly addressed, minimizing downtime and keeping production running smoothly.

Control and usability are also key features of this machine. It is compatible with popular CAD/CAM software, including AutoCAD, SolidWorks, and CorelDRAW, allowing users to seamlessly integrate their design workflows with the cutting process. The easy-to-use interface supports broad programming capabilities, making it accessible for both experienced operators and newcomers. This flexibility enhances the machine’s adaptability across different applications and industries.

The working environment for the Laser Glass Cutting Machine is optimized at a temperature of 26℃, providing stable operating conditions that contribute to consistent cutting performance and machine longevity. This controlled environment further enhances the precision and quality of the cuts produced.

In summary, this laser glass cutting machine is an ideal solution for anyone looking to achieve high quality, high precision cuts in thick glass materials. Its capabilities extend to stained glass cutting and complex irregular shapes, making it versatile for artistic and industrial applications. With its combination of powerful laser technology, energy efficiency, environmental safety, reliable warranty, and user-friendly software compatibility, it stands out as a leading choice in the market for high precision laser cutting machines.

Features:

- Product Name: Laser Glass Cutting Machine

- Weight: 3500kg

- Working Frequency: 50HZ/60HZ

- Cutting Precision: ±0.01mm

- Drive Motor: XY Linear Motor + Grating Ruler

- Cutting Width: 0.03-25mm

- High precision stained glass cutting machine suitable for detailed designs

- Efficient stained glass cutting machine optimized for various glass types

- Advanced colored glass cutting machine capable of handling complex patterns

Technical Parameters:

| Splitting Laser Source Wavelength | 10.6µm |

| Cutting Speed | Adjustable From 0-500mm/s |

| Control System | HTI Control |

| Impulse Frequency | 1-100kHz |

| Splitting Laser Source Power | 150W (options: 250W/350W) |

| Safety Features | Includes Emergency Stop Button, Protective Cover, Laser Safety Windows, And Automatic Power-off When The Cover Is Open For Safe Operation |

| Positioning Accuracy | ±2μm |

| Splitting Laser Source | RFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W (options: 250W/350W) - 150W(250W/350W) 1-100kHz Water Cooling |

| Cutting Thickness | Ultra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm |

| Cutting Accuracy | ±0.01mm |

Applications:

The CKD Laser Glass Cutting Machine series, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-SP6070S-50E, and many others, is designed to meet a wide range of glass cutting needs. Originating from China and certified with ISO and CE, these machines are ideal for various application occasions, especially in industries requiring precision and efficiency in glass processing.

One of the key application scenarios for the CKD laser glass cutting machines is in the production of polygonal glass components. The advanced splitting laser source with a wavelength of 10.6µm allows for highly accurate cutting of polygonal glass shapes, making it perfect for architectural glass, automotive glass parts, and decorative glass elements. The broad programming support and compatibility with popular CAD/CAM software such as AutoCAD, SolidWorks, and CorelDRAW make it easy for operators to design and cut complex polygonal shapes with ease.

For small glass laser cutting requirements, CKD offers models with customizable work sizes around 610*700mm X 2, which are perfect for crafting small glass products like smartphone screens, watch covers, and other precision glass components. The easy-to-use control software ensures smooth operation even in small batch productions, providing flexibility and high performance in compact manufacturing environments.

The CKD laser glass cutting machines also excel as thick glass laser cutting machines. With laser power options ranging from 30W to 90W, these machines can efficiently cut thicker glass sheets used in applications such as tempered glass panels, glass table tops, and industrial glass components. The built-in silencing system reduces operating noise to 70dB, making it suitable for low-noise working environments without compromising cutting quality or speed.

Thanks to the robust packaging with wooden vacuum packaging and a supply ability of 60 sets per month, CKD ensures timely delivery within 25-45 days, with flexible payment terms including L/C and T/T. Whether you need a polygonal glass cutting machine, a small glass laser cutting machine, or a thick glass laser cutting machine, CKD’s product line offers versatile solutions tailored to diverse industrial needs.

Customization:

CKD offers a comprehensive range of Laser Glass Cutting Machines, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E. Manufactured in China and certified with ISO CE standards, these machines are designed to meet diverse cutting needs with exceptional precision.

Our Laser Glass Cutting Machines are equipped with advanced CNC technology, ensuring cutting precision of ±0.01mm and pulse width of less than 10ps. The splitting laser source operates at a wavelength of 10.6µm, providing efficient and clean cuts on various types of glass. With dimensions available in 2150mm × 2080mm × 1960mm or 2550mm × 2080mm × 1960mm, these machines are adaptable to various workspace requirements.

CKD specializes in customizing solutions for colored glass cutting machines, environmental protection glass laser cutting machines, and polygonal glass cutting machines, catering to unique industry demands. Each unit is packaged securely with wooden vacuum packaging to ensure safe delivery.

The minimum order quantity is 1 set, with a supply ability of 60 sets per month. Delivery time ranges from 25 to 45 days, and pricing is negotiable to accommodate customer requirements. Payment terms include L/C and T/T options for convenient transactions.

Choose CKD Laser Glass Cutting Machines for reliable performance, high precision, and versatile customization capabilities tailored to your specific glass cutting needs.

Support and Services:

Our Laser Glass Cutting Machine is designed to deliver precision and efficiency for all your glass processing needs. To ensure optimal performance, please follow the recommended maintenance and operational guidelines outlined in the user manual.

If you encounter any technical issues, our dedicated support team is available to assist with troubleshooting, repairs, and parts replacement. We offer comprehensive after-sales services including installation support, software updates, and on-site training to help you maximize the machine's capabilities.

Regular maintenance checks are advised to prolong the lifespan of the laser components and maintain cutting accuracy. Replacement parts and consumables are readily available through our authorized service centers.

For detailed technical support, please refer to the troubleshooting section in the manual or visit our online support portal where FAQs, instructional videos, and software downloads are accessible to registered users.

We are committed to providing reliable and timely service to ensure your Laser Glass Cutting Machine operates at peak performance, minimizing downtime and maximizing productivity.

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is carefully packaged to ensure safe delivery. It is first wrapped with protective foam to prevent any damage during transit. The machine is then placed inside a sturdy wooden crate, reinforced with metal straps for added security. All sensitive components are cushioned with anti-static materials, and the packaging is clearly labeled with handling instructions such as "Fragile" and "This Side Up" to guarantee careful handling.

Shipping:

We offer multiple shipping options to accommodate your needs, including air freight, sea freight, and express courier services. The Laser Glass Cutting Machine is shipped with full insurance coverage to protect against loss or damage. Tracking information is provided once the product leaves our facility, allowing you to monitor the shipment until it reaches your location. Our logistics team coordinates with reliable carriers to ensure timely and safe delivery worldwide.