Revolutionize Your Glass Cutting Process with Our Laser Glass Cutting Machine To Speed 0-500mm/s

-

Whether CNCYes

-

Splitting Laser Source Pulse Frequency1-100kHz

-

Acceleration1G

-

Compatibility With Automation SystemsSupports Integration With Major Automation Systems, Including Robot Interfaces And Automatic Loading/unloading Systems. Standard Industrial Communication Protocols (like Modbus, OPC) Are Supported.

-

Transmission SystemRack And Pinion

-

Cutting Area400mm*500mm/ 600*700mm/ 600*900mm

-

Repeatability±1.5μm

-

Splitting Laser SourceRFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W (options: 250W/350W) - 150W(250W/350W) 1-100kHz Water Cooling

-

Wavelength Coverage1064nm

-

Cutting Accuracy±0.01mm

-

Laser TypeFiber Laser

-

SoftwareCypCut

-

ApplicationGlass Cutting, Glass Engraving

-

Cutting Size40*50cm*2

-

Control SystemCNC

-

Weight3500kg

-

VoltageAC 220V/380V

-

Cut Speed0-500mm/s

-

Worktable Size1300mm X 2500mm

-

Power SupplyAC 220V/380V, 50/60Hz

-

Power80W

-

Control SoftwareCypCut

-

Linear SpeedUp To 1000mm/s

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Revolutionize Your Glass Cutting Process with Our Laser Glass Cutting Machine To Speed 0-500mm/s

Product Description:

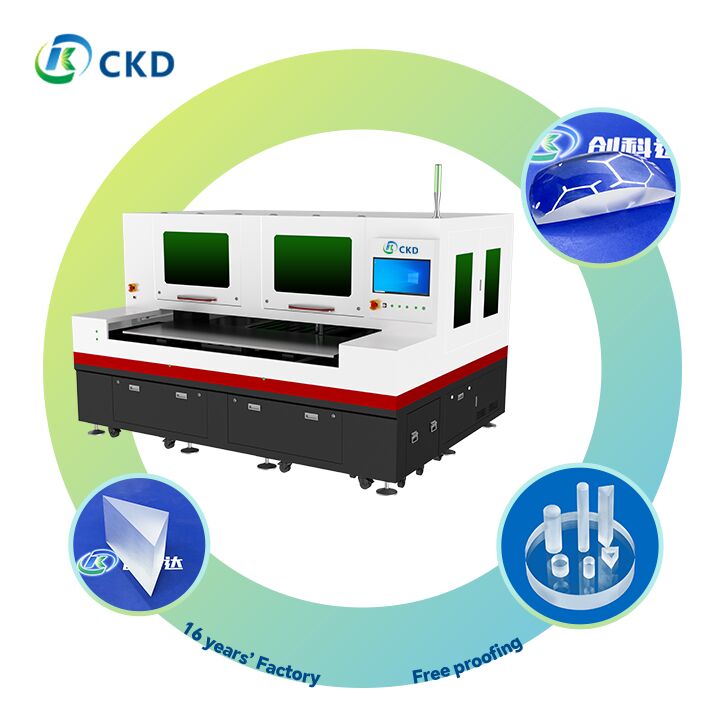

The Laser Glass Cutting Machine is an advanced piece of equipment designed to meet the precise demands of glass processing industries. Specially engineered as an optical glass laser cutting machine, it utilizes cutting-edge fiber laser technology to deliver exceptional performance in cutting various types of glass with remarkable accuracy and efficiency. This machine excels in handling a wide range of glass thicknesses, from ultra-thin sheets measuring just 0.03mm to thick glass panels up to 25mm, making it highly versatile for diverse applications.

One of the standout features of this fiber laser cutting machine is its superior positioning accuracy, which is maintained within ±2μm. This level of precision ensures that every cut, whether straight or curved, is executed flawlessly, minimizing material waste and enhancing the overall quality of the final product. Such meticulous accuracy is particularly valuable when working with delicate optical glass, where even minor deviations can compromise the integrity of the material.

The machine is also expertly designed to accommodate irregular glass cutting, a task that requires both flexibility and precision. Its sophisticated control system allows for complex cutting patterns and shapes, enabling manufacturers to produce customized glass components tailored to specific design requirements. Whether the project involves decorative glass panels, specialized lenses, or uniquely shaped glass pieces, this laser glass cutting machine provides the reliability and performance needed to achieve outstanding results.

To ensure optimal operation and longevity, the machine incorporates an efficient water cooling system. This cooling mechanism effectively manages the heat generated during the laser cutting process, protecting both the laser source and the glass material from thermal damage. By maintaining stable operating temperatures, the water cooling system contributes to consistent cutting quality and extends the service life of the equipment.

In terms of physical specifications, the machine is available in two dimension options: 2150mm × 2080mm × 1960mm and 2550mm × 2080mm × 1960mm. These compact footprints make it suitable for various workshop sizes, providing flexibility in installation and integration into existing production lines. The machine operates efficiently at standard working frequencies of 50HZ and 60HZ, ensuring compatibility with electrical systems worldwide.

Overall, this laser glass cutting machine represents a significant advancement in glass processing technology. Combining the precision of fiber laser cutting with robust engineering and smart cooling solutions, it delivers unmatched performance for both standard and irregular glass cutting tasks. Its ability to handle a broad range of glass thicknesses, coupled with high positioning accuracy and reliable operation, makes it an indispensable tool for industries requiring top-quality optical glass laser cutting machines.

Whether used in manufacturing optical components, architectural glass elements, or intricate decorative glass designs, this machine stands out as a powerful and versatile solution. By choosing this fiber laser cutting machine, businesses can enhance productivity, reduce material waste, and achieve superior cutting precision, ultimately driving innovation and quality in glass fabrication processes.

Features:

- Product Name: Laser Glass Cutting Machine

- Laser Wavelength: 1064nm

- Splitting Laser Source: RFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W with options for 250W and 350W

- Laser Source Cooling: Water Cooling System

- Working Frequency: 50HZ/60HZ

- Splitting Laser Source Pulse Frequency: 1-100kHz

- Optimal Environmental Conditions: Works best in temperatures between 15°C and 30°C with 20%-80% relative humidity

- Suitable Environments: Ideal for cleanrooms or industrial environments

- Specialized for colored glass cutting machine applications

- Designed as an environmental protection glass laser cutting machine

- Capable of precision cutting for polygonal glass cutting machine tasks

Technical Parameters:

| Dimension | 2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm |

| Work Size | 610*700mm X 2, Customizable |

| Splitting Laser Source Power | 150W (options: 250W/350W) |

| Cutting Precision | ±0.01mm |

| Working Environment | 26℃ |

| Splitting Laser Source Pulse Frequency | 1-100kHz |

| Cutting Speed | Adjustable From 0-500mm/s |

| Maintenance Requirements | Recommend Optical Alignment Every 200 Hours, And Coolant Replacement Every 1000 Hours. Regular Remote Diagnostics And Software Updates Available. |

| Cutting Accuracy | ±0.01mm |

| Advantages | Irregular-shape High-speed Cutting High Cutting Quality, No Taper, No Burr, Small Chipping High Yield Rate, Low Consumables And Energy-saving No Pollution, No Powder, And No Wastewater |

Applications:

The CKD Laser Glass Cutting Machine series, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, and many others, offers an advanced solution for various glass cutting needs. Originating from China and certified with ISO and CE standards, these machines are designed to meet the highest quality and safety requirements. With a splitting laser source wavelength of 10.6µm and an RFC02 (Radio Frequency CO2) laser type, the CKD machines provide precise and efficient cutting performance.

These laser glass cutting machines are widely used in multiple application occasions and scenarios. They are perfect for industries that require thick glass laser cutting machine capabilities, allowing for clean, accurate cuts on thicker glass materials without compromising the integrity of the glass. The environmental protection glass laser cutting machine feature ensures that the cutting process is eco-friendly, reducing emissions and waste compared to traditional glass cutting methods.

The stained glass cutting machine function expands the usability of CKD laser cutters into the artistic and decorative glass sector. Whether producing intricate stained glass patterns or detailed designs, the CKD models offer exceptional precision and versatility. Their rack and pinion transmission system combined with high-quality TPI linear guides ensures smooth and stable movement, allowing for cutting widths ranging from 0.03mm up to 25mm, accommodating a wide variety of glass thicknesses and designs.

These laser glass cutting machines are ideal for manufacturers of architectural glass, automotive glass, decorative glass products, and customized glass artworks. The machines’ wooden vacuum packaging guarantees safe delivery within 25-45 days, with a supply ability of 60 sets per month. Payment terms are flexible, including L/C and T/T options, with pricing negotiated to fit customer needs.

Overall, CKD’s laser glass cutting machines are perfectly suited for industries and workshops focusing on thick glass processing, environmentally conscious production, and artistic stained glass applications. Their advanced technology, durable construction, and reliable performance make them indispensable tools for modern glass fabrication and design.

Customization:

The CKD Laser Glass Cutting Machine is an advanced environmental protection glass laser cutting machine designed to meet diverse cutting needs. Featuring multiple models including CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, and CKD-SP6070C-80E, this small glass laser cutting machine offers versatile solutions for various glass types.

Originating from China and certified with ISO and CE standards, this laser glass cutting machine ensures high quality and reliability. It supports a minimum order quantity of 1 set and offers flexible pricing through negotiation. Packaging is done with wooden vacuum packaging to ensure safe delivery within 25-45 days. Payment terms include L/C and T/T, with a supply ability of 60 sets per month.

The machine uses a splitting laser source with a wavelength of 10.6µm and water cooling method for efficient heat dissipation. It operates at a power of 150W, with optional upgrades to 250W or 350W to accommodate different cutting requirements. The operating noise level is maintained at 70dB, equipped with a built-in silencing system suitable for low-noise environments.

This laser glass cutting machine specializes in irregular glass cutting and is applicable to a wide range of materials including ultra clear glass, plain white glass, high borosilicate glass, quartz glass, optical glass, cover glass, camera glass cover, phone glass cover, car glass, LCD screens, K9 glass, filter cutting, and mirror cutting. Its precision and efficiency make it ideal for various industrial and commercial glass cutting applications.

Support and Services:

Our Laser Glass Cutting Machine is designed to deliver precision and efficiency for all your glass processing needs. To ensure optimal performance and longevity of your machine, we provide comprehensive technical support and services.

Technical Support:

Our team of experienced technicians is available to assist with installation, setup, and troubleshooting. We offer remote support as well as on-site service to resolve any technical issues promptly. Regular software updates and maintenance guidelines are provided to keep your machine running smoothly.

Training Services:

We provide detailed training sessions for operators to maximize the use of the Laser Glass Cutting Machine. Training covers machine operation, safety protocols, maintenance procedures, and best practices for achieving high-quality cuts.

Maintenance and Repairs:

Scheduled maintenance services are available to prevent unexpected downtime. Our support includes calibration, part replacement, and repair services carried out by certified technicians using genuine spare parts.

Customization and Upgrades:

We offer customization options to tailor the machine according to specific production requirements. Upgrade packages are available to enhance machine capabilities with the latest technology advancements.

Documentation:

Comprehensive user manuals, maintenance guides, and troubleshooting documentation are provided with the machine. Additional resources and FAQs are accessible online to support your operational needs.

Our commitment is to provide reliable support and quality service to ensure your Laser Glass Cutting Machine operates at peak performance, helping you achieve precise and efficient glass cutting results.

Packing and Shipping:

Our Laser Glass Cutting Machine is carefully packaged to ensure it arrives at your location in perfect condition. The machine is securely placed in a sturdy wooden crate with custom foam padding to protect all sensitive components during transit. All accessories, manuals, and cables are neatly packed in separate compartments within the crate to prevent any damage.

For shipping, we offer multiple options including sea freight, air freight, and express courier services to meet your delivery timeline and budget. Each shipment is fully insured and tracked from our warehouse to your doorstep. Our professional logistics team coordinates the entire process, ensuring timely and safe delivery worldwide.

Before dispatch, every Laser Glass Cutting Machine undergoes a thorough quality inspection and testing to guarantee optimal performance upon arrival. We also provide detailed handling instructions and support documentation to facilitate smooth installation and setup.

Choose our reliable packaging and shipping services for a hassle-free purchase experience and prompt delivery of your Laser Glass Cutting Machine.