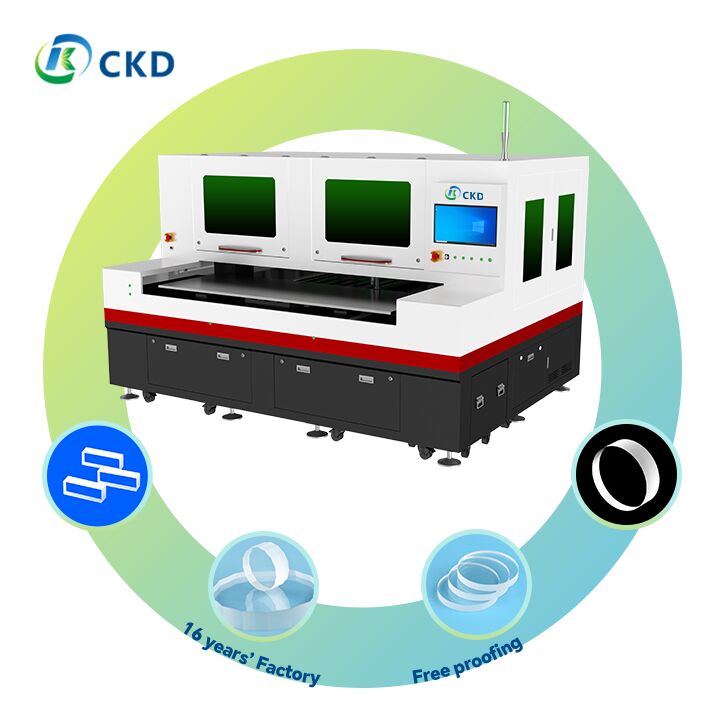

Upgrade Your Glass Cutting Process with Our Advanced Laser Glass Cutting Machine To Chipping ≤5μm

-

Splitting Laser SourceRFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W (options: 250W/350W) - 150W(250W/350W) 1-100kHz Water Cooling

-

Cutting Thickness0.03~25mm

-

Whether CNCYes

-

Customizable OptionsCustom Options Available For Table Size, Laser Power (up To 500W), And Special Cutting Heads (like For Curved Or Micro-level Cutting) To Meet Specific Needs.

-

Cutting Width0.03-25mm

-

Pulse Width<10ps

-

MobilityEquipped With Heavy-duty Wheels For Easy Movement And Repositioning, With Locking Mechanisms For Stability

-

AdvantagesIrregular-shape High-speed Cutting High Cutting Quality, No Taper, No Burr, Small Chipping High Yield Rate, Low Consumables And Energy-saving No Pollution, No Powder, And No Wastewater

-

Working Area1500mm X 3000mm

-

Wavelength1064nm

-

Cutting Size150*150cm*2

-

Cooling MethodWater Cooling

-

ApplicationGlass Cutting

-

Weight3500kg

-

MaterialsGlass, Acrylic, Plastic, Wood, Etc.

-

Repeatability Accuracy±0.02mm

-

Graphic FormatPLT/DXF/BMP/JPG/GIF/PNG/TIF

-

Accuracy Of Segmentation±0.01mm

-

Cutting Precision±0.01mm

-

Accuracy Grade±0.01mm

-

Accuracy±0.05mm

-

NaneGlass Laser Cutting Machine

-

Support Graphic FormatPLT, DXF, AI, Etc.

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Upgrade Your Glass Cutting Process with Our Advanced Laser Glass Cutting Machine To Chipping ≤5μm

Product Description:

The Single Table Glass Cutting Machine is an advanced Fiber Laser Cutting Machine designed specifically for precision and efficiency in glass processing. This Small Glass Laser Cutting Machine combines cutting-edge technology with user-friendly features to deliver exceptional performance for various glass cutting applications.

One of the standout features of this machine is its remarkably low operating noise level. With an operating noise level of just 70dB, the machine is equipped with a built-in silencing system that ensures minimal sound disturbance. This makes it highly suitable for low-noise environments such as laboratories, commercial workshops, and other noise-sensitive settings, allowing operators to work comfortably without the distraction of excessive noise.

The laser system operates at a wavelength of 1064nm, which is ideal for cutting and engraving glass materials with high precision. The stable and consistent wavelength ensures smooth and clean cuts, reducing the risk of cracking or chipping the glass. This wavelength also allows for versatile applications, making the Single Table Glass Cutting Machine perfect for various industries, including electronics, automotive, and decorative glass manufacturing.

Equipped with a pulse frequency range from 1Hz to an impressive 1000kHz, the Fiber Laser Cutting Machine offers extraordinary flexibility and control over the cutting process. This wide range of pulse frequencies allows users to tailor the laser output to different glass thicknesses and cutting requirements, enhancing both speed and accuracy. Whether performing delicate engraving or deep cutting, the machine’s pulse frequency capabilities ensure optimal results every time.

The transmission system utilizes a reliable rack and pinion mechanism, which guarantees precise and smooth movement of the cutting head across the glass surface. This system enhances the stability and accuracy of the cutting process, preventing any unwanted vibrations or deviations. As a result, the Single Table Glass Cutting Machine can achieve high-quality cuts with minimal waste and maximum efficiency.

Driving the machine’s movement is an advanced XY linear motor combined with a grating ruler for position feedback. This drive motor configuration provides rapid, precise, and repeatable positioning, ensuring that every cut is executed exactly as programmed. The linear motor’s high responsiveness enhances overall productivity by reducing cutting time and improving throughput. Meanwhile, the grating ruler ensures that the position feedback is accurate, enabling fine adjustments and consistent performance during continuous operation.

Compact yet powerful, this Small Glass Laser Cutting Machine is ideal for businesses looking to optimize their glass processing capabilities without compromising on space or quality. Its single table design allows for easy loading and unloading of glass sheets, making it suitable for small to medium-sized production runs. Additionally, the machine’s intuitive control system simplifies operation, making it accessible even to users with limited experience in laser cutting technology.

In summary, the Single Table Glass Cutting Machine is a highly efficient, precise, and quiet Fiber Laser Cutting Machine that meets the diverse needs of modern glass processing industries. Its low noise level, wide pulse frequency range, optimal wavelength, dependable transmission system, and advanced drive motor technology combine to deliver superior cutting performance. Whether you require intricate engraving or high-speed cutting, this Small Glass Laser Cutting Machine provides a reliable and cost-effective solution for all your glass cutting needs.

Features:

- Product Name: Laser Glass Cutting Machine

- Drive Motor: XY Linear Motor + Grating Ruler for precise movement

- Weight: 3500kg ensuring stability during operation

- Positioning Accuracy: ±2μm for high precision cutting

- Splitting Laser Source Power: 150W standard, with optional 250W or 350W for enhanced performance

- Cutting Thickness Range: 0.03~25mm suitable for various glass types

- Ideal for use as a Stained Glass Cutting Machine, Polygonal Glass Cutting Machine, and Thick Glass Laser Cutting Machine

Technical Parameters:

| Environmental Conditions | Works Best In Temperatures Between 15°C And 30°C, With 20%-80% Relative Humidity, Suitable For Cleanrooms Or Industrial Environments |

| Mobility | Equipped With Heavy-duty Wheels For Easy Movement And Repositioning, With Locking Mechanisms For Stability |

| Compatibility with Automation Systems | Supports Integration With Major Automation Systems, Including Robot Interfaces And Automatic Loading/unloading Systems. Standard Industrial Communication Protocols (like Modbus, OPC) Are Supported. |

| Applicable Materials | Ultra Clear Class, Plain White Glass High Borosilicate Glass, Quartz Glass Optical Glass, Cover Glass, Camera Glass Cover, Etc. Phone Glass Cover, Car Glass, Camera Glass Cover, Etc. LCD Screen, K9 Glass, Filter Cutting, Mirror Cutting, Etc. |

| Dimension | 2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm |

| Impulse Frequency | 1-100khz |

| Cutting Accuracy | ±0.01mm |

| Splitting Laser Source Cooling Method | Water Cooling |

| Cutting Thickness | Ultra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm |

| Working Voltage | 220V |

Applications:

The CKD brand Laser Glass Cutting Machine series, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070D-50E, and CKD-SP6070S-50E among others, offers versatile and high-precision cutting solutions for various glass processing needs. Manufactured in China and certified with ISO and CE, these machines are designed to meet the highest industry standards, ensuring safety, efficiency, and reliability. Their advanced HTI control system combined with the RFC02 Radio Frequency CO2 laser source, available in 150W, 250W, or 350W power options, allows users to perform precise cuts on a wide range of glass materials, including environmental protection glass and colored glass.

The environmental protection glass laser cutting machine from CKD is ideal for applications in industries where eco-friendly processing is paramount. It is widely used in manufacturing architectural glass panels, automotive glass components, and decorative glass products, where precision and minimal waste are crucial. The ability to accurately cut colored glass makes these machines indispensable in the production of stained glass art, colored glass facades, and specialty glassware, enabling manufacturers to achieve intricate designs and smooth edges without compromising the glass's integrity.

In addition to industrial manufacturing, the CKD laser glass cutting machines are frequently employed in research and development settings, where experimentation with new glass types and cutting techniques requires a reliable and adaptable cutting platform. The machine's robust design, with a weight of 3500kg and wooden vacuum packaging for safe transportation, ensures durability and stability in various working environments. With a supply capability of 60 sets per month and flexible payment terms including L/C and T/T, CKD caters to both small-scale workshops and large manufacturing facilities.

Delivery timelines range from 25 to 45 days, allowing businesses to plan their production schedules effectively. Whether it’s cutting complex shapes in environmental protection glass or handling the unique challenges of colored glass cutting, CKD’s laser glass cutting machines provide a perfect balance of precision, speed, and environmental sustainability. The machines' water-cooled laser source and cutting wavelength of 1064nm further enhance their performance, making them a top choice for glass processing professionals worldwide.

Customization:

CKD offers a comprehensive Product Customization Service for our Laser Glass Cutting Machine series, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50E, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80E, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80E, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80E, CKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80E, CKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E.

Manufactured in China and certified with ISO and CE, our machines guarantee reliable quality and performance. We specialize in Single Table Glass Cutting Machines and Small Glass Laser Cutting Machines designed for high precision with cutting accuracy of ±0.01mm and repeatability of ±1.5μm, ensuring minimal chipping of ≤5μm.

Each High Precision Laser Cutting Machine operates on a working voltage of 220V and weighs 3500kg, highlighting robust build quality. We offer flexible pricing through negotiation and accept payment terms via L/C and T/T. Our minimum order quantity is 1 set, packaged securely with wooden vacuum packaging to ensure safe delivery.

With a supply ability of 60 sets per month, we ensure timely delivery within 25-45 days. CKD is committed to customizing solutions tailored to your specific glass cutting needs, providing advanced technology and dependable service for your business.

Support and Services:

Our Laser Glass Cutting Machine is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide detailed user manuals, installation guidance, and operation training to help you get started quickly and safely.

Our technical support team is available to assist with troubleshooting, maintenance advice, and software updates. We offer remote diagnostics and on-site service options to minimize downtime and maximize productivity.

Regular maintenance services, including calibration and component inspection, are recommended to maintain cutting precision and extend the machine's lifespan. Replacement parts and consumables are readily available to keep your machine operating smoothly.

We are committed to continuous improvement and welcome customer feedback to enhance our products and services. Our goal is to provide reliable, efficient, and user-friendly laser glass cutting solutions tailored to your needs.

Packing and Shipping:

Our Laser Glass Cutting Machine is carefully packaged to ensure it arrives in perfect condition. Each unit is securely wrapped with protective materials and placed inside a sturdy wooden crate to prevent any damage during transit. The packaging is designed to withstand rough handling and environmental factors, guaranteeing the safety of the product.

For shipping, we offer multiple options including sea freight, air freight, and express courier services. All shipments are tracked and insured to provide peace of mind. We coordinate with reliable logistics partners to ensure timely and safe delivery to your specified destination. Additionally, detailed handling instructions and assembly guides are included to facilitate smooth installation upon arrival.