Maximize Your Glass Cutting Efficiency with Cutting-Edge Laser Glass Cutting Machine To Accuracy±0.01mm

-

Control SoftwareCompatible With Popular CAD/CAM Software Like AutoCAD, SolidWorks, And CorelDRAW. Easy To Use Interface With Broad Programming Support.

-

Compatibility With Automation SystemsSupports Integration With Major Automation Systems, Including Robot Interfaces And Automatic Loading/unloading Systems. Standard Industrial Communication Protocols (like Modbus, OPC) Are Supported.

-

Splitting Laser Source Laser TypeRFC02 (Radio Frequency CO2)

-

Cooling SystemWater Cooling

-

Minimum Cutting Burr≤5μm

-

Dimension2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm

-

Key Selling PointsUltra Fast Picesecond

-

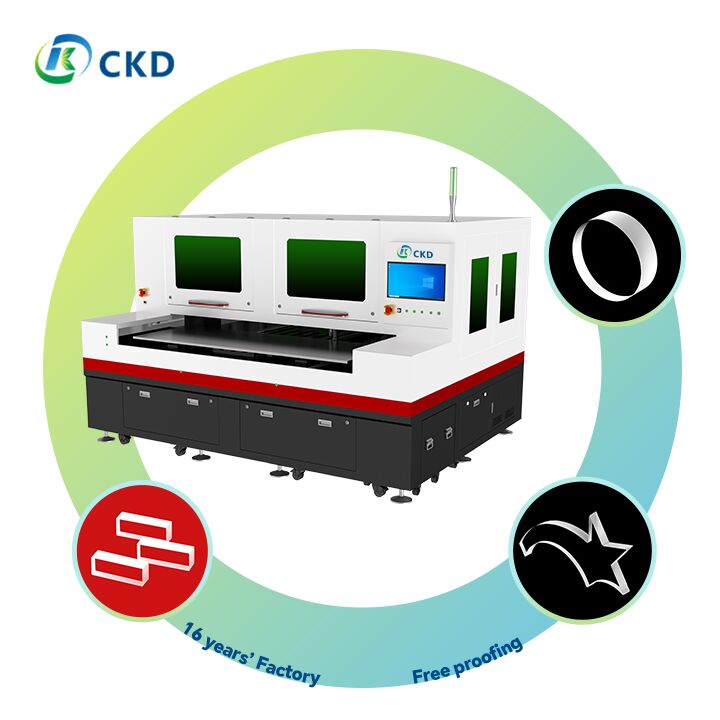

NameGlass Cutting And Splitting Machine (All-in-One)

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Maximize Your Glass Cutting Efficiency with Cutting-Edge Laser Glass Cutting Machine To Accuracy±0.01mm

Product Description:

The Fiber Laser Cutting Machine is a state-of-the-art solution designed for precision and efficiency in glass cutting applications. As an Environmental Protection Glass Laser Cutting Machine, it combines advanced technology with eco-friendly features to ensure minimal environmental impact while delivering outstanding performance. This High Precision Laser Cutting Machine is engineered to meet the demanding requirements of industries that require meticulous and accurate glass cutting.

One of the most remarkable features of this machine is its exceptional cutting accuracy, boasting a tolerance of ±0.01mm. This level of precision ensures that every cut is clean, smooth, and exact, reducing material waste and improving the quality of the final product. Such accuracy is critical for applications where even the slightest deviation can lead to substantial issues in assembly or final usage.

Repeatability is equally important in any cutting technology, and this Fiber Laser Cutting Machine excels with a repeatability of ±1.5μm. This means it can consistently reproduce the same high-quality cuts over multiple production runs, making it ideal for both small-scale precision tasks and high-volume manufacturing environments. The reliability provided by this repeatability ensures that manufacturers can trust the machine for continuous operation without concerns about quality degradation over time.

The cutting speed of this machine is highly versatile, adjustable from 0 to 500mm/s. This adjustable speed range allows operators to optimize the cutting process based on the specific type of glass and the complexity of the design. Whether the job requires slow, intricate cuts or faster, straightforward slicing, this machine can be fine-tuned to deliver optimal results, balancing speed with precision effectively.

Integral to the machine’s superior performance is the use of TPI linear guides. Known for their smooth and stable motion, TPI linear guides enhance the machine’s operational accuracy and durability. This choice of high-quality components ensures minimal mechanical wear and tear, contributing to the machine’s longevity and consistent performance over extended periods of use.

Maintenance is a critical consideration for any precision equipment, and this Environmental Protection Glass Laser Cutting Machine comes with clear, practical guidelines to keep it running at peak performance. It is recommended that optical alignment be performed every 200 hours to maintain cutting accuracy and prevent any drift in laser positioning. Additionally, coolant replacement is advised every 1000 hours to ensure the cooling system functions efficiently, protecting the laser and other components from overheating.

To further support users, the machine offers regular remote diagnostics and software updates. These services help in quickly identifying and resolving any potential issues, minimizing downtime. The software updates also ensure that the machine remains compatible with the latest technological advancements and industry standards, future-proofing the investment made by the users.

In summary, this Fiber Laser Cutting Machine represents a perfect blend of precision, reliability, and environmental responsibility. It is an ideal choice for those seeking a High Precision Laser Cutting Machine capable of handling demanding glass cutting tasks with exceptional accuracy and repeatability. With adjustable cutting speeds, robust TPI linear guides, and comprehensive maintenance support, it stands out as a top-tier Environmental Protection Glass Laser Cutting Machine designed to meet the evolving needs of modern manufacturing.

Features:

- Product Name: Laser Glass Cutting Machine

- Also Known As: Glass Cutting And Splitting Machine (All-in-One)

- Pulse Width: Less than 10 picoseconds (<10ps)

- Cutting Precision: ±0.01mm for highly accurate cuts

- Positioning Accuracy: ±2μm ensuring precise glass processing

- Warranty: Comes with a 2-year warranty covering major components such as the laser source and control system

- Service: 24/7 technical support with both remote and on-site service options

- Eco-Friendly Design: Environmental protection glass laser cutting machine, promoting sustainable manufacturing

- Type: Fiber Laser Cutting Machine providing efficient and reliable glass cutting

- Size: Small glass laser cutting machine suitable for compact workspace and versatile applications

Technical Parameters:

| Drive Motor | XY Linear Motor + Grating Ruler |

| Cutting Area | 400mm × 500mm / 600mm × 700mm / 600mm × 900mm |

| Splitting Laser Source Pulse Frequency | 1-100kHz |

| Impulse Frequency | 1-100kHz |

| Repeatability | ±1.5μm |

| Chipping | ≤5μm |

| Brand | CKD |

| Cutting Thickness | Ultra-clear Glass Single Cut ≤19mm, Blue Glass Double Cut ≤19mm |

| Material | Glass |

| Applicable Industries | Glassware Industry: Optical Glass, K9 Glass, Ultra-thin Glass; Houseware Industry: High-borosilicate Glass, Quartz Glass, Sanitary Ware Glass; Vehicle Industry: Automotive Glass, Car Windshield, etc.; New Energy: Photovoltaic Glass; Home Appliance: Home Appliance Glass, Panel Lighting Glass; Real Estate: Architectural Decoration, Bathroom Glass, etc. |

Applications:

The CKD Laser Glass Cutting Machine series, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-SP6070S-50E, CKD-SP6070S-60E, and others, is designed for precision and efficiency in glass cutting applications. Manufactured in China and certified with ISO CE standards, these machines feature ultra-fast picosecond infrared lasers capable of operating at pulse frequencies from 1Hz up to 1000kHz, ensuring high-quality cuts with minimal thermal impact. With a weight of 3500kg and packaged in wooden vacuum packaging for secure delivery, the CKD laser glass cutting machines deliver reliable performance with a supply ability of 60 sets per month and flexible payment terms (L/C, T/T).

These machines are ideal for a variety of application occasions and scenarios across multiple industries. In the glassware industry, they excel in cutting optical glass, K9 glass, and ultra-thin glass, providing smooth and precise edges that are essential for high-end optical products. The single table glass cutting machine configuration is perfect for workshops and factories requiring a compact but highly efficient solution for batch production with consistent quality.

For the houseware industry, CKD’s polygonal glass cutting machines can accurately process high-borosilicate glass, quartz glass, and sanitary ware glass, enabling manufacturers to produce durable and aesthetically pleasing products such as glass cookware, laboratory glassware, and bathroom accessories. The advanced laser technology minimizes chipping and cracking, which is vital for maintaining product integrity.

In the automotive sector, these small glass laser cutting machines are widely used to cut automotive glass and car windshields with precision, supporting the production of safety glass components that meet stringent automotive standards. The ultra-fast picosecond laser ensures minimal heat-affected zones, preserving the structural strength and clarity of the glass.

The new energy industry benefits from CKD laser glass cutting machines by utilizing them to process photovoltaic glass with high accuracy, enhancing the efficiency and durability of solar panels. Additionally, in the home appliance and real estate industries, these machines are utilized to cut home appliance glass, panel lighting glass, architectural decoration glass, and bathroom glass with complex shapes and high-quality finishes, supporting innovative design and construction needs.

With a delivery time of 25-45 days and customizable pricing, CKD’s laser glass cutting machines offer versatile solutions for businesses seeking advanced, reliable, and efficient glass cutting technology. Whether you require a single table glass cutting machine for focused production, a polygonal glass cutting machine for complex shapes, or a small glass laser cutting machine for space-saving operations, CKD provides a comprehensive range of models to meet diverse industrial demands.

Customization:

CKD offers a comprehensive product customization service for our Laser Glass Cutting Machine series, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50E, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80E, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80E, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80E, CKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80E, CKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E. Manufactured in China and certified with ISO and CE, these machines support small minimum order quantities starting from just one unit.

Our Laser Glass Cutting Machines are ideal for polygonal glass cutting machine applications and irregular glass cutting tasks, delivering ultra-fast picosecond laser precision. Equipped with a splitting laser source power of 150W, with optional upgrades to 250W or 350W, these machines ensure high efficiency and accuracy. They are designed with environmental protection in mind, offering an eco-friendly glass laser cutting machine solution with standby power consumption around 500W and an average cutting power consumption of only 2.5kW.

Pricing is negotiable to meet your specific requirements. Each unit is securely packaged using wooden vacuum packaging to ensure safe delivery within 25-45 days. Payment terms include L/C and T/T options, and the supply ability is up to 60 sets per month, accommodating both small and large orders.

For optimal performance, we recommend optical alignment every 200 hours and coolant replacement every 1000 hours. Our maintenance services also include regular remote diagnostics and software updates to keep your machine running smoothly. The machines operate at a voltage of AC220V with a power consumption below 8KW, ensuring energy efficiency and reliable operation.

Choose CKD for your customized Laser Glass Cutting Machine needs and benefit from advanced technology, environmental protection features, and flexible service tailored to your polygonal and irregular glass cutting applications.

Support and Services:

Our Laser Glass Cutting Machine is designed to provide precise and efficient cutting solutions for various types of glass materials. To ensure optimal performance and longevity of the machine, please follow the recommended usage guidelines and maintenance procedures.

Technical Support:

Our technical support team is available to assist you with installation, setup, troubleshooting, and operational guidance. We provide detailed user manuals and video tutorials to help you understand the machine's features and functions. Should you encounter any technical issues, please ensure that you have the machine model and serial number ready for faster assistance.

Maintenance Services:

Regular maintenance is crucial for maintaining the accuracy and efficiency of the Laser Glass Cutting Machine. This includes routine cleaning of the laser lens, checking and replacing consumable parts, and software updates. We recommend scheduling periodic maintenance checks with our certified technicians to prevent unexpected downtime.

Training and Consultation:

We offer comprehensive training sessions for operators to maximize the capabilities of the machine. Our experts can provide on-site or remote training tailored to your specific application needs. Additionally, consultation services are available to help you integrate the laser cutting machine into your existing production workflow effectively.

Warranty and Repairs:

The Laser Glass Cutting Machine comes with a limited warranty covering manufacturing defects and hardware malfunctions under normal operating conditions. In the event of a malfunction, our service center will diagnose and repair the machine promptly. Extended warranty and service contracts are also available for additional peace of mind.

Spare Parts and Upgrades:

We supply genuine spare parts and accessories to ensure compatibility and maintain machine performance. Upgrades to software and hardware components are periodically released to enhance functionality and efficiency. Please consult our support team to learn more about available upgrades.

For optimal results, always operate the machine in accordance with the safety instructions and guidelines provided in the user manual.

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is carefully packaged to ensure safe delivery and protection during transit. It is securely placed in a sturdy wooden crate with foam padding and shock-absorbing materials to prevent any damage. All delicate components are wrapped individually with protective covers. The packaging is designed to be moisture-resistant and tamper-evident, ensuring the product arrives in perfect condition.

Shipping:

We offer worldwide shipping for the Laser Glass Cutting Machine through trusted logistics partners. The shipment is handled with care, and tracking information will be provided once the order is dispatched. Depending on the destination, shipping options include air freight, sea freight, or express courier services. Customs documentation and export compliance are managed by our experienced team to facilitate smooth delivery.