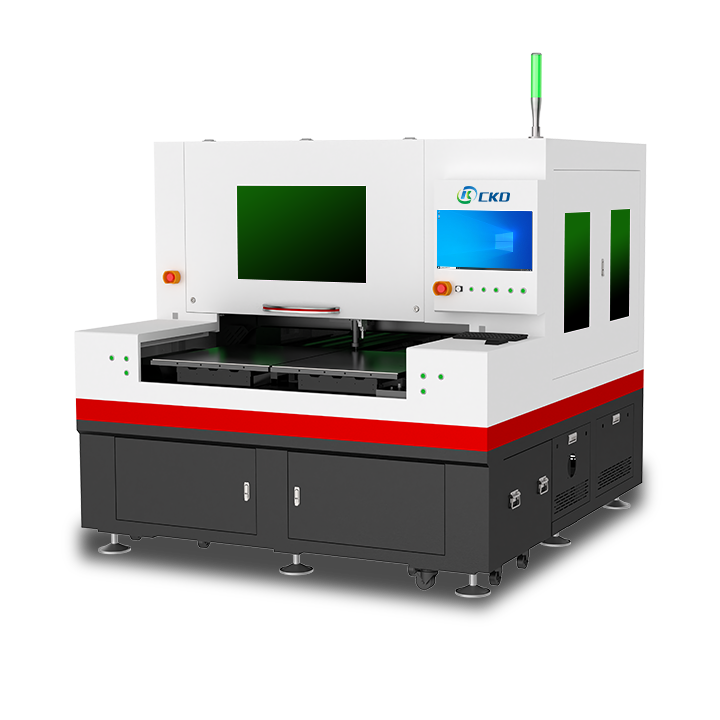

Experience Fast and Accurate Glass Cutting with Our and Durable Laser Glass Cutting Machine o Chipping ≤5μm

-

Maintenance RequirementsRecommend Optical Alignment Every 200 Hours, And Coolant Replacement Every 1000 Hours. Regular Remote Diagnostics And Software Updates Available.

-

Control SystemHTI Control

-

MaterialGlass

-

Cutting Width0.03-25mm

-

Minimum Cutting Burr≤5um

-

Cutting Area400mm*500mm/ 600*700mm/ 600*900mm

-

Dimension2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm

-

Pulse Frequency1Hz - 1000kHz

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Experience Fast and Accurate Glass Cutting with Our and Durable Laser Glass Cutting Machine o Chipping ≤5μm

Product Description:

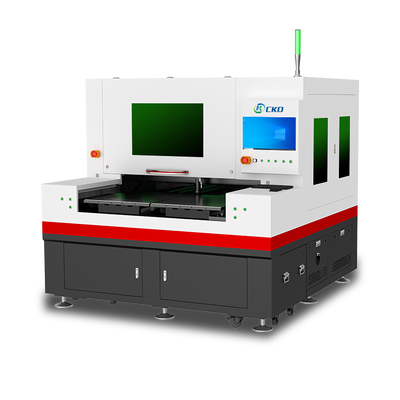

The Laser Glass Cutting Machine is a state-of-the-art solution designed to deliver precision, efficiency, and versatility in the glass cutting industry. Equipped with the advanced HTI Control system, this machine ensures seamless operation and user-friendly interface, making it ideal for both professional manufacturers and artisans working with various types of glass. Whether you are cutting stained glass, colored glass, or environmental protection glass, this laser cutting machine offers unparalleled performance and reliability.

One of the standout features of this Laser Glass Cutting Machine is its powerful splitting laser source, available with options of 150W, 250W, and 350W. The standard 150W laser source provides sufficient power to cut through glass materials with thickness ranging from 0.03mm up to 25mm, accommodating a wide variety of glass types and applications. For more demanding cutting tasks, the higher power options of 250W and 350W allow for increased cutting speed and the ability to handle thicker materials, making this machine highly adaptable to different production requirements.

Designed to operate on a working voltage of 220V, this laser glass cutting machine is compatible with standard industrial power supplies, ensuring stable and efficient energy consumption. The machine’s robust construction, combined with the high-quality laser source, guarantees consistent cutting quality and long-term durability, reducing maintenance costs and downtime in your production line.

Speed is a critical factor in any manufacturing process, and the Laser Glass Cutting Machine excels in this aspect with a linear cutting speed of up to 1000mm/s. This high-speed capability enables rapid processing of glass sheets, significantly boosting productivity without compromising on precision. Whether producing intricate designs on stained glass or making straight cuts on colored glass panels, the machine’s swift motion control ensures clean edges and minimal material wastage.

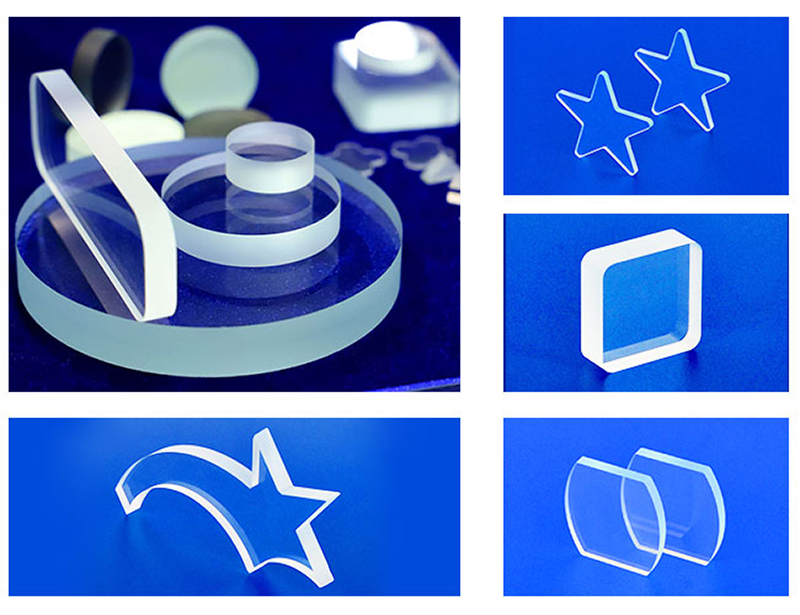

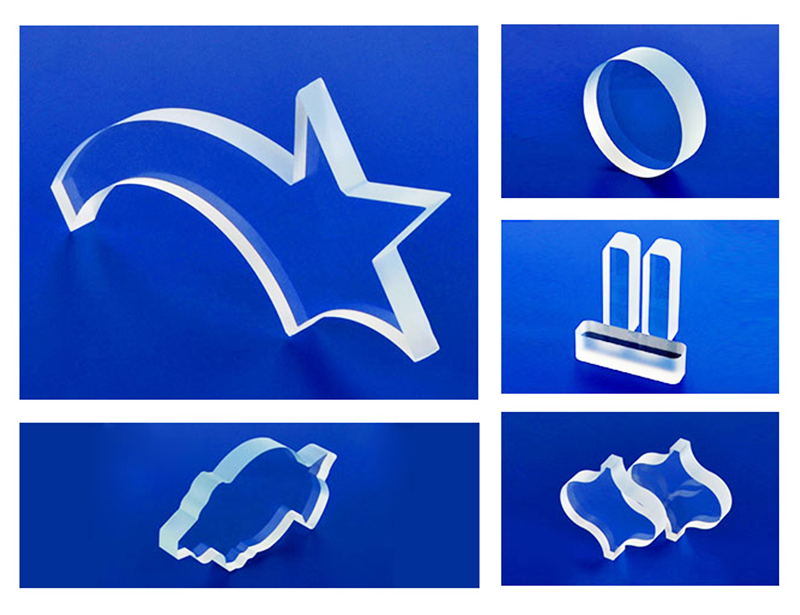

This machine is especially suited for stained glass cutting, where intricate patterns and delicate cuts are essential. Its precise laser technology allows artisans and manufacturers to create complex designs with ease, enhancing the aesthetic appeal of stained glass products. Additionally, the machine’s environmental protection glass laser cutting capabilities emphasize its role in sustainable manufacturing. By using laser technology, the process minimizes material waste and eliminates the need for harmful chemicals or abrasive cutting methods, making it an eco-friendly choice for modern glass processing.

The versatility of this colored glass cutting machine extends to various industries, including architectural glass fabrication, decorative glass production, and industrial glass processing. Its ability to handle different glass colors and types without compromising cutting quality makes it an indispensable tool for businesses aiming to meet diverse customer demands. Furthermore, the precision of laser cutting ensures that even the most intricate designs are executed with accuracy, enhancing the overall quality and value of the finished products.

In summary, the Laser Glass Cutting Machine with HTI Control is a high-performance, versatile, and environmentally conscious solution for all glass cutting needs. Its powerful laser source options, broad cutting thickness range, high linear speed, and compatibility with standard working voltage make it a reliable choice for cutting stained glass, colored glass, and environmental protection glass. By integrating this advanced cutting technology into your production process, you can achieve superior cutting precision, increased efficiency, and sustainable manufacturing practices.

Features:

- Product Name: Laser Glass Cutting Machine

- Linear Speed: Up To 1000mm/s for efficient cutting

- Cutting Area Options: 400mm*500mm, 600mm*700mm, and 600mm*900mm

- Working Voltage: 220V for stable performance

- Transmission System: Rack and Pinion for precise movement

- Cutting Precision: ±0.01mm ensuring high accuracy

- Environmental protection glass laser cutting machine suitable for eco-friendly operations

- Specially designed colored glass cutting machine for vibrant glass materials

- Advanced colored glass cutting machine capability for diverse glass types

Technical Parameters:

| Cutting Precision | ±0.01mm |

| Pulse Frequency | 1Hz - 1000kHz |

| Cutting Thickness | 0.03~25mm |

| Acceleration | 1G |

| Cutting Width | 0.03-25mm |

| Dimension | 2150mm × 2080mm × 1960mm / 2550mm × 2080mm × 1960mm |

| Repeatability | ±1.5μm |

| Supported Image and Text Formats | AI, PLT, DXF, BMP, Dst, DWg, LAS, DXP |

| Noise Level | Operating Noise Level is 70dB, with a built-in silencing system, suitable for low-noise environments |

| Wavelength | 1064nm |

Applications:

The CKD Laser Glass Cutting Machine series, featuring models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, and many others, is a highly versatile and precise cutting solution originating from China. With ISO and CE certifications, this advanced machine is designed to meet the diverse needs of various industries by delivering exceptional cutting precision of ±0.01mm. Its water cooling system ensures consistent performance and longevity, making it ideal for high-demand production environments.

These cutting machines are perfectly suited for irregular glass cutting, enabling manufacturers to produce complex shapes and designs with ease. The polygonal glass cutting machine capability allows for precise geometric cuts, which are essential in industries requiring exact glass dimensions and shapes. Additionally, the colored glass cutting machine function supports the processing of vibrant and tinted glass types, expanding the range of creative possibilities for designers and fabricators.

Applicable materials include ultra-clear glass, plain white glass, high borosilicate glass, quartz glass, optical glass, cover glass, camera glass covers, phone glass covers, automotive glass, LCD screens, K9 glass, as well as filter and mirror glass. This extensive material compatibility makes the CKD Laser Glass Cutting Machine an invaluable asset across multiple sectors.

The machine finds broad application across numerous industries. In the glassware industry, it caters to optical glass, K9 glass, and ultra-thin glass cutting needs. The houseware industry benefits from its ability to handle high-borosilicate, quartz, and sanitary ware glass. The vehicle industry relies on it for automotive glass and car windshield production. Emerging sectors such as new energy utilize it for photovoltaic glass, while home appliance manufacturers use it for panel lighting and appliance glass. The real estate and architectural decoration sectors apply this technology to bathroom glass and various structural glass elements.

Equipped with a reliable rack and pinion transmission system, the CKD Laser Glass Cutting Machine ensures smooth and accurate operations. Its packaging involves wooden vacuum packaging for secure transportation, with delivery times ranging from 25 to 45 days. With a supply ability of 60 sets per month and flexible payment terms including L/C and T/T, CKD offers a dependable and customizable solution for businesses seeking high-quality laser glass cutting technology. The minimum order quantity is one unit, and pricing is negotiable to suit customer requirements.

Customization:

CKD offers comprehensive product customization services for the Laser Glass Cutting Machine, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E. Manufactured in China and certified with ISO and CE, these machines are designed to meet a wide range of glass cutting needs.

Our laser glass cutting machines support ultra-clear glass single cuts up to 19mm and blue glass double cuts up to 19mm, with an adjustable cutting speed ranging from 0 to 500mm/s and a cutting precision of ±0.01mm. They are ideal for cutting various materials such as ultra-clear glass, plain white glass, high borosilicate glass, quartz glass, optical glass, cover glass, camera glass cover, phone glass cover, car glass, LCD screens, K9 glass, as well as filters and mirrors.

We specialize in customization for environmental protection glass laser cutting machines, colored glass cutting machines, and irregular glass cutting applications, ensuring that each machine is tailored to your specific production requirements. Packaging is handled with wooden vacuum packaging to ensure safety during transit.

The minimum order quantity is 1 set, with a supply ability of 60 sets per month. Delivery time is typically between 25 to 45 days, and pricing is negotiable to accommodate your budget. Payment terms include L/C and T/T, providing flexible options for your convenience.

Choose CKD for reliable, high-precision laser glass cutting machines that can be customized to your unique needs, enhancing your production capabilities with advanced technology and exceptional service.

Support and Services:

Our Laser Glass Cutting Machine is designed to provide precision and efficiency for all your glass cutting needs. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services.

Technical Support:

Our team of experienced technicians is available to assist you with installation, calibration, and troubleshooting. We provide detailed user manuals and video tutorials to guide you through the setup and operation process. Should you encounter any issues, our support staff can help diagnose problems remotely or schedule on-site visits if necessary.

Maintenance Services:

Regular maintenance is crucial for maintaining the accuracy and reliability of your laser glass cutting machine. We offer scheduled maintenance plans including cleaning, alignment checks, software updates, and replacement of worn parts to minimize downtime and extend the lifespan of your equipment.

Training:

We provide comprehensive training programs for your operators and technical staff to ensure they are proficient in using and maintaining the machine safely and effectively. Training can be conducted at your facility or remotely through online sessions.

Warranty and Repair:

The Laser Glass Cutting Machine comes with a standard warranty covering manufacturing defects and hardware malfunctions. In case of a breakdown, our repair services ensure quick turnaround times using genuine replacement parts to get your machine back up and running promptly.

Software Updates:

We continuously improve our machine software to enhance functionality and user experience. Customers receive regular updates that can be easily installed to keep your system current with the latest features and security improvements.

Spare Parts Supply:

We maintain an inventory of essential spare parts and consumables to support your operational needs. Ordering replacement parts is streamlined to ensure minimal disruption to your production schedules.

For further assistance and detailed service options, please refer to the product documentation provided with your Laser Glass Cutting Machine.

Packing and Shipping:

![]()

The Laser Glass Cutting Machine is carefully packaged to ensure it arrives in perfect condition. It is securely placed in a custom-fitted foam mold inside a sturdy wooden crate to protect against shocks and vibrations during transit. All delicate components are wrapped with protective materials to prevent any damage.

For shipping, the machine is handled by experienced logistics providers specializing in heavy and sensitive equipment. It is shipped via sea freight or air freight depending on the destination and urgency. Clear labeling and documentation are included to facilitate smooth customs clearance and delivery.

Upon receipt, please inspect the packaging for any signs of damage before signing the delivery note. Our support team is available to assist with installation guidance and any concerns regarding the shipment.