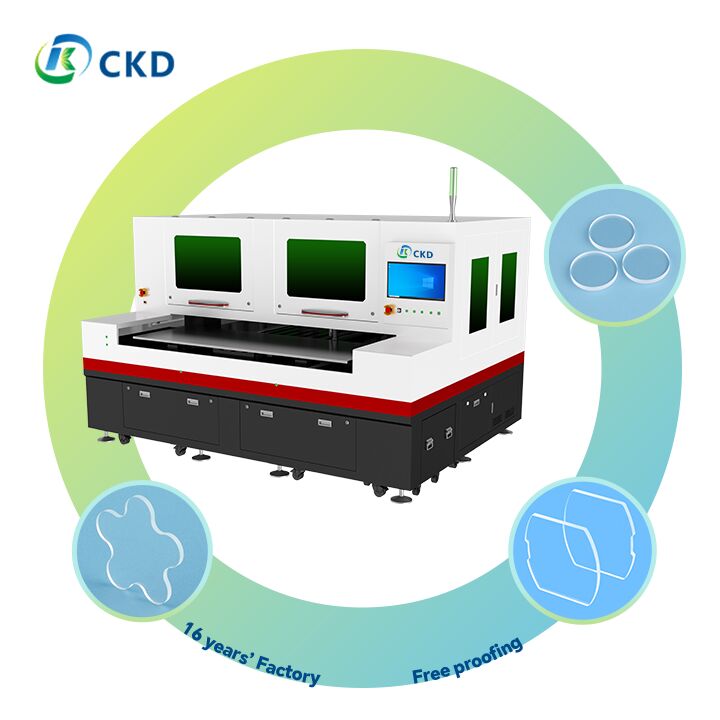

Innovative Laser Glass Cutting Machine for Fast and Precise Glass Cutting Solutions To Accuracy±0.01mm

-

Drive MotorXY Linear Motor + Optical Grating Scale

-

Weight3500kg

-

Splitting Laser Source Laser TypeRFC02 (Radio Frequency CO2)

-

Control SystemHTI Control

-

Linear Guide BrandTPI

-

Linear SpeedUp To 1000mm/s

-

Positioning Accuracy±2μm

-

BrandCKD

-

Wavelength Coverage1064nm

-

NaneGlass Laser Cutting Machine

-

Laser Power200W

-

Cutting Size40*50cm*2

-

Worktable Size1300mm X 2500mm

-

Cutting Precision±0.01mm

-

Driving SystemHTI

-

Machinery Efficiency0-500mm/s

-

Control SoftwareCypCut

-

Working TableHoneycomb/Aluminum Blade

-

Chipping≤200μm

-

Cutting Accuracy±0.01mm

-

Cutting Width0.03-25mm

-

Drilling Thickness<19mm

-

Accuracy±0.01mm

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Innovative Laser Glass Cutting Machine for Fast and Precise Glass Cutting Solutions To Accuracy±0.01mm

Product Description:

The Laser Glass Cutting Machine is a state-of-the-art solution designed to meet the precise and demanding requirements of modern glass processing. Engineered with advanced technology, this machine excels in delivering exceptional performance, making it an ideal choice for industries that require meticulous glass cutting capabilities. Whether you are working with ultra-clear glass or blue glass, this equipment offers unparalleled cutting precision and efficiency.

![]()

![]()

![]()

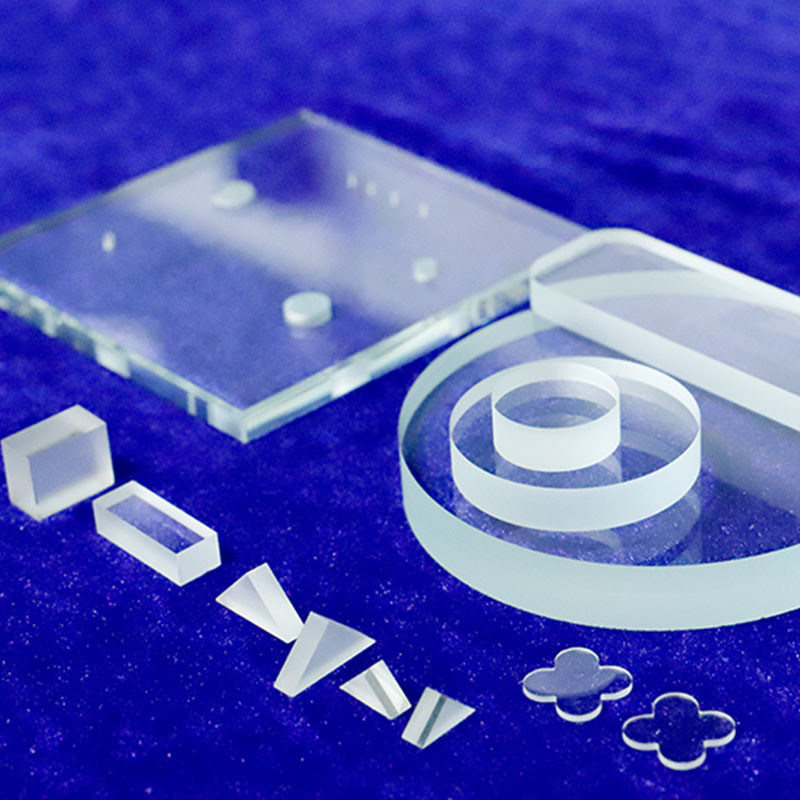

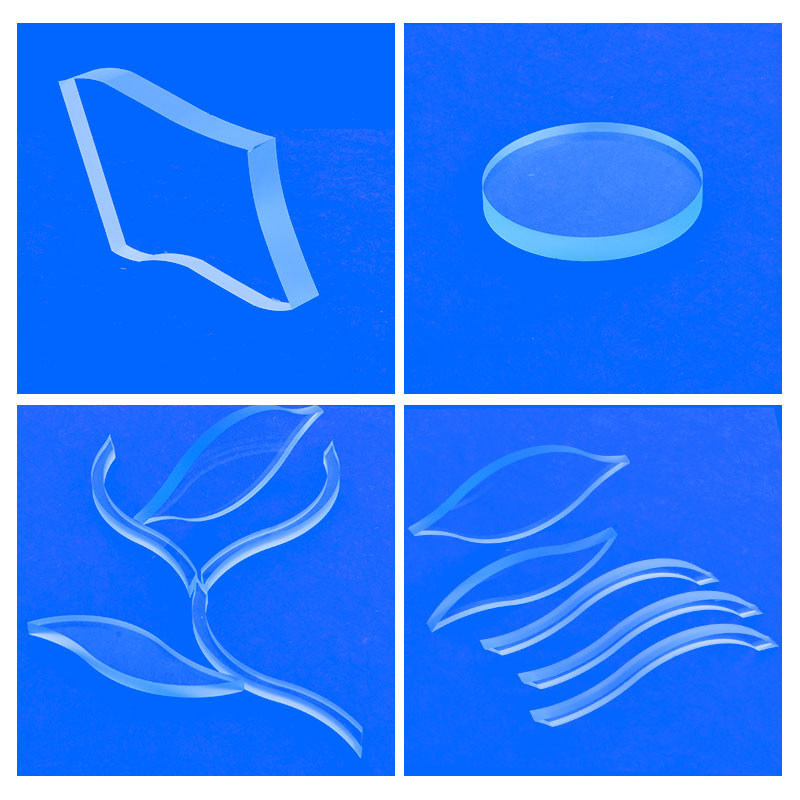

One of the standout features of this Single Table Glass Cutting Machine is its ability to handle different types of glass with remarkable ease. It can cut ultra-clear glass with a single cut thickness of up to 19mm, ensuring smooth and clean edges without compromising the integrity of the material. For blue glass, the machine supports double cuts up to 19mm thickness, offering versatility for various glass cutting applications. This flexibility is particularly beneficial for projects involving diverse glass types and thicknesses.

Powered by a variety of laser power options ranging from 30W to 90W (30/50/60/75/80/90w), the machine provides users with the ability to select the optimal power setting tailored to their specific cutting needs. This range of laser power options ensures that the machine can efficiently handle different glass thicknesses and cutting complexities, enhancing overall productivity and precision. The ultra-fast picosecond laser technology employed in this machine is a key selling point, enabling incredibly rapid cutting speeds while maintaining high accuracy. This fast cutting capability significantly reduces processing time, making it an excellent choice for businesses looking to boost production efficiency without sacrificing quality.

The working frequency of the Laser Glass Cutting Machine is adaptable to both 50HZ and 60HZ power supplies, ensuring compatibility with electrical systems worldwide. This flexibility makes it a practical choice for international operations or facilities with varying power standards. Additionally, the machine features an acceleration rate of 1G, which contributes to smooth and stable cutting performance, minimizing vibrations and ensuring clean cuts even during high-speed operations.

Designed as a Small Glass Laser Cutting Machine, it is compact yet powerful, making it suitable for workshops and production lines where space is limited but high-quality glass cutting is essential. Its compact footprint does not compromise its capabilities; instead, it offers an efficient, user-friendly interface that simplifies the cutting process and reduces operator fatigue. This combination of size and performance makes it a preferred option for small to medium-sized enterprises looking to enhance their glass cutting capabilities without investing in bulky, complex machinery.

Moreover, the Laser Glass Cutting Machine excels in irregular glass cutting, a feature that is increasingly in demand for custom glass shapes and designs. This capability allows manufacturers to produce uniquely shaped glass pieces with intricate patterns and curves, opening up new creative possibilities for architectural, automotive, and decorative glass applications. The precision of the laser cutting process ensures that even the most complex irregular shapes are cut cleanly and accurately, reducing material waste and rework.

In summary, the Laser Glass Cutting Machine combines cutting-edge picosecond laser technology with versatile power options and adaptable working conditions to deliver exceptional glass cutting performance. Its ability to handle ultra-clear and blue glass up to 19mm thick, coupled with its suitability for irregular glass cutting, makes it an indispensable tool for industries requiring high precision and efficiency. Whether you are seeking a reliable Single Table Glass Cutting Machine or a compact Small Glass Laser Cutting Machine, this product stands out as a top-tier choice that meets a wide range of glass cutting demands with speed, accuracy, and reliability.

Features:

- Product Name: Laser Glass Cutting Machine

- Brand: CKD

- Positioning Accuracy: ±2μm

- Repeatability: ±1.5μm

- Key Selling Points: Ultra Fast Picosecond laser technology

- Maintenance Requirements:

- Recommend Optical Alignment Every 200 Hours

- Coolant Replacement Every 1000 Hours

- Regular Remote Diagnostics and Software Updates Available

- Ideal for applications requiring a Small glass laser cutting machine

- Advanced Fiber Laser Cutting Machine technology ensures precision and efficiency

- Compact design suitable as a Small glass laser cutting machine for various industries

Technical Parameters:

| Energy Consumption | Standby Power Is About 500W, And Average Power Consumption During Cutting Is 2.5kW. Energy-efficient With Eco-friendly Modes. |

| Splitting Laser Source Power | 150W (options: 250W/350W) |

| Linear Guide Brand | TPI |

| Working Frequency | 50HZ/60HZ |

| CNC | Yes |

| Pulse Width | <10ps |

| Laser Wavelength | 1064nm |

| Positioning Accuracy | ±2μm |

| Compatibility with Automation Systems | Supports Integration With Major Automation Systems, Including Robot Interfaces And Automatic Loading/unloading Systems. Standard Industrial Communication Protocols (like Modbus, OPC) Are Supported. |

| Customizable Options | Custom Options Available For Table Size, Laser Power (up To 500W), And Special Cutting Heads (like For Curved Or Micro-level Cutting) To Meet Specific Needs. |

Applications:

The CKD Laser Glass Cutting Machine series, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070D-50E, and others, is designed to meet diverse glass processing needs with exceptional precision and efficiency. Originating from China and certified with ISO CE, this advanced cutting equipment boasts a positioning accuracy of ±2μm and operates on a standard 220V working voltage, ensuring reliable and stable performance across various industrial environments.

One of the standout features of CKD’s laser glass cutting machines is their ability to handle irregular glass cutting tasks with remarkable ease. Whether it’s complex shapes or unique designs, the machine’s RFC02 Radio Frequency CO2 laser source coupled with water cooling technology ensures clean, precise edges without damaging the glass material. This makes it an ideal choice for applications requiring intricate patterns or custom shapes, expanding the scope of creative and functional possibilities in glass manufacturing.

The machines are also highly compatible with popular CAD/CAM software such as AutoCAD, SolidWorks, and CorelDRAW, providing users with an easy-to-use interface and broad programming support. This compatibility facilitates seamless integration into existing design workflows, allowing for efficient customization and rapid prototyping. Such flexibility makes the CKD laser glass cutting machines perfect for industries like architectural glass fabrication, automotive glass customization, decorative glass production, and specialty glass manufacturing.

Another significant application scenario for these machines involves colored glass cutting. The precision and gentle cutting process preserve the vibrant colors and coatings on glass surfaces, making the CKD colored glass cutting machine series an excellent solution for producing decorative panels, stained glass art, and colored glass components for electronic displays. The wooden vacuum packaging ensures the machines are delivered safely and securely within 25-45 days, with flexible payment options including L/C and T/T.

With a supply ability of 60 sets per month and a minimum order quantity of just one, the CKD Laser Glass Cutting Machine series is well-suited for both small-scale workshops and large manufacturing facilities. The negotiated pricing further enhances accessibility, making these cutting-edge machines a valuable investment for any business aiming to enhance their glass cutting capabilities, especially for irregular glass cutting and colored glass cutting projects.

Customization:

CKD offers a range of High Precision Laser Cutting Machines designed for Irregular glass cutting with exceptional accuracy and efficiency. Our Small glass laser cutting machine models include CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E.

Manufactured in China, all CKD laser glass cutting machines are certified with ISO and CE standards, ensuring top quality and safety. These machines utilize a reliable Rack And Pinion transmission system combined with TPI linear guides to achieve smooth and precise movements.

The cutting area options available are 400mm*500mm, 600mm*700mm, and 600mm*900mm, catering to various glass sizes. Laser power options range from 30W to 90W, including 30W, 50W, 60W, 75W, 80W, and 90W, enabling efficient cutting of different glass thicknesses and types.

With a pulse frequency range from 1Hz to 1000kHz, our machines provide flexibility for diverse cutting requirements. We offer a minimum order quantity of just 1 unit, with pricing negotiated to suit your needs.

All products are carefully packed using wooden vacuum packaging to ensure safe delivery within 25-45 days. Payment terms include L/C and T/T for your convenience. CKD supports a supply ability of 60 sets per month, ready to meet your production demands.

Choose CKD’s High Precision Laser Cutting Machine for your Irregular glass cutting needs and experience the reliability and performance of an advanced Small glass laser cutting machine.

Support and Services:

Our Laser Glass Cutting Machine is designed to deliver precision and efficiency for all your glass processing needs. To ensure optimal performance and longevity, we provide comprehensive technical support and services.

Technical Support:

Our team of experts is available to assist you with installation, setup, and troubleshooting. We offer detailed user manuals and video tutorials to help you understand the machine’s features and maintenance requirements. Should you encounter any issues, our support staff can guide you through diagnostics and solutions to minimize downtime.

Maintenance Services:

Regular maintenance is crucial for maintaining cutting accuracy and machine reliability. We provide scheduled maintenance services, including cleaning, calibration, and component inspection. Our technicians use genuine replacement parts to ensure the machine operates at peak performance.

Training Programs:

To help your staff operate the Laser Glass Cutting Machine safely and efficiently, we offer comprehensive training sessions. These cover machine operation, safety protocols, basic troubleshooting, and routine maintenance procedures.

Software Updates:

We continuously improve our machine’s software to enhance functionality and user experience. Registered users receive timely notifications and support for software updates and upgrades.

Warranty and Repair:

The Laser Glass Cutting Machine comes with a standard warranty covering manufacturing defects and hardware malfunctions. In case of repairs, our service centers are equipped to handle all technical issues promptly, ensuring minimal disruption to your operations.

For further assistance and service requests, please refer to the official support channels provided with your product documentation.

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is securely packaged using high-quality materials to ensure safe delivery. The machine is first wrapped in protective foam padding to prevent any scratches or damage during transit. It is then placed inside a sturdy wooden crate that is reinforced with metal brackets for additional stability. All delicate components are individually cushioned and fixed in place to avoid movement. The packaging is clearly labeled with handling instructions, including "Fragile" and "This Side Up," to guarantee careful transportation.

Shipping:

We offer reliable shipping options for the Laser Glass Cutting Machine, including air freight and sea freight, depending on customer requirements and destination. The machine is shipped with comprehensive insurance coverage to protect against any potential loss or damage. Our logistics partners provide real-time tracking so customers can monitor their shipment status from dispatch to delivery. Upon arrival, installation support and guidance are available to ensure the machine is set up correctly and ready for operation.