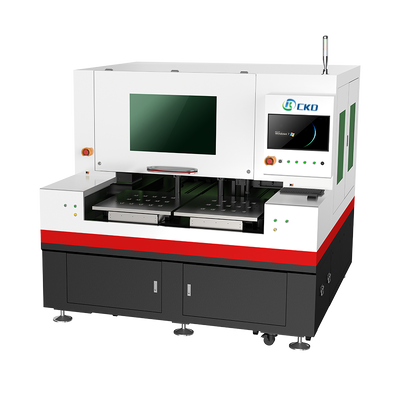

Ultra Fast Picesecond Single Table Glass Cutting Machine for Smooth and Accurate Cuts Maintenance Every 200 Hours To Chipping ≤5μm

-

Splitting Laser Source Wavelength10.6µm

-

Chipping≤5μm

-

Key Selling PointsUltra Fast Picesecond

-

Working Frequency50HZ/60HZ

-

Pulse Frequency1Hz - 1000kHz

-

Control SoftwareCompatible With Popular CAD/CAM Software Like AutoCAD, SolidWorks, And CorelDRAW. Easy To Use Interface With Broad Programming Support.

-

Repeatability±1.5μm

-

Cutting SpeedAdjustable From 0-500mm/s

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Ultra Fast Picesecond Single Table Glass Cutting Machine for Smooth and Accurate Cuts Maintenance Every 200 Hours To Chipping ≤5μm

Product Description:

The Environmental Protection Glass Laser Cutting Machine is a state-of-the-art solution designed to meet the demanding requirements of modern glass processing industries. This high precision laser cutting machine offers unparalleled performance, combining speed, accuracy, and environmental sustainability to deliver exceptional results on various types of optical glass. Engineered with the latest RFC02 (Radio Frequency CO2) laser technology, this optical glass laser cutting machine ensures precise, clean, and efficient cutting, making it an ideal choice for manufacturers seeking superior quality and productivity.

One of the standout features of this laser glass cutting machine is its versatile cutting area options. It is available in three different sizes: 400mm x 500mm, 600mm x 700mm, and 600mm x 900mm. This range allows users to select the best fit for their specific production needs, whether they are working on small-scale projects or larger glass panels. The cutting speed is fully adjustable from 0 to 500mm per second, providing flexibility to optimize the process based on material thickness and desired finish quality.

Powered by the RFC02 laser source, this machine delivers high-speed cutting capabilities with outstanding precision. The laser type ensures minimal thermal impact on the glass, resulting in cuts with no taper, no burr, and very small chipping. This precision cutting not only enhances the aesthetic quality of the final product but also improves yield rates by reducing material waste. The high cutting quality achieved by this machine supports the production of intricate, irregular-shaped glass components without compromising speed or efficiency.

In addition to performance, the Environmental Protection Glass Laser Cutting Machine emphasizes sustainability. The cutting process produces no pollution, no powder, and no wastewater, making it an environmentally friendly option for glass manufacturers. This eco-conscious design aligns with industry trends toward greener production methods and helps companies reduce their environmental footprint while maintaining high output standards.

Maintenance of the machine is straightforward and designed to keep downtime to a minimum. It is recommended to perform optical alignment every 200 hours to ensure optimal laser performance and cutting accuracy. Additionally, coolant replacement is advised every 1000 hours to maintain the system’s cooling efficiency and extend the lifespan of the components. The machine also supports regular remote diagnostics and software updates, allowing for timely troubleshooting and continuous improvements in operational efficiency without requiring on-site technical visits.

With its combination of advanced laser technology, flexible cutting area options, and environmentally conscious design, this optical glass laser cutting machine is an excellent investment for businesses seeking to enhance their manufacturing capabilities. Whether producing high-precision optical components or intricate glass designs, this machine delivers consistent, high-quality results with low consumable costs and energy consumption.

In summary, the Environmental Protection Glass Laser Cutting Machine offers a comprehensive solution for high precision glass cutting needs. Its RFC02 laser source ensures superior cutting quality with no taper or burr, while the adjustable cutting speed and multiple cutting area sizes provide versatility. The machine’s low environmental impact and efficient maintenance requirements make it a sustainable and cost-effective choice. For industries focused on precision, efficiency, and environmental responsibility, this optical glass laser cutting machine represents the cutting-edge in laser glass processing technology.

Features:

- Product Name: Laser Glass Cutting Machine

- Key Selling Points: Ultra Fast Picosecond technology for precise and efficient cutting

- Splitting laser source pulse frequency: 1-100kHz

- Voltage & Power: Less than 8KW, AC220V

- Cutting Thickness Range: 0.03~25mm, suitable for various glass types

- Environmental Conditions: Works best in temperatures between 15°C and 30°C, with 20%-80% relative humidity

- Ideal for use in cleanrooms or industrial environments

- Highly efficient Fiber Laser Cutting Machine technology incorporated

- Specialized as a colored glass cutting machine, capable of handling different glass colors with precision

- Reliable and durable Fiber Laser Cutting Machine suitable for various glass cutting applications

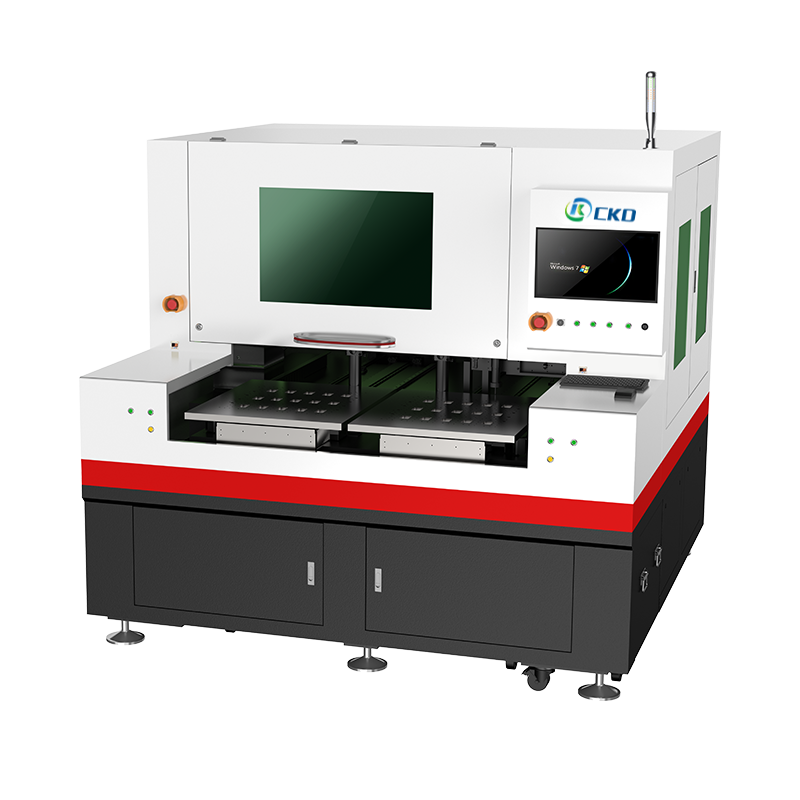

Technical Parameters:

| Laser Power | 30/50/60/75/80/90W |

| Work Size | 610*700mm X 2 (Customizable) |

| Voltage, Power | <8KW, AC220V |

| Cutting Thickness | 0.03~25mm |

| Positioning Accuracy | ±2μm |

| Splitting Laser Source Wavelength | 10.6µm |

| Advantages | Irregular-shape High-speed Cutting, High Cutting Quality, No Taper, No Burr, Small Chipping, High Yield Rate, Low Consumables and Energy-saving, No Pollution, No Powder, and No Wastewater |

| Cooling System | Water Cooling |

| Splitting Laser Source Cooling Method | Water Cooling |

| Supported Image and Text Formats | AI, PLT, DXF, BMP, Dst, DWg, LAS, DXP |

Applications:

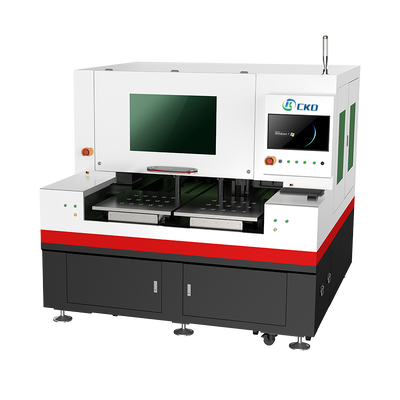

The CKD Laser Glass Cutting Machine series, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, and many others, is a state-of-the-art solution designed for precision glass cutting applications. Manufactured in China and certified with ISO and CE standards, these machines guarantee high quality and reliability. With a minimum order quantity of just one unit, businesses can easily integrate these advanced cutting systems into their production lines.

Ideal for a wide range of application occasions, the CKD Single Table Glass Cutting Machine is widely used in industries requiring precise and efficient glass processing. Whether it is for architectural glass panels, automotive glass components, or decorative colored glass products, this fiber laser cutting machine excels in delivering clean, burr-free cuts with a minimum cutting burr of ≤5um. This ensures superior edge quality and reduces the need for secondary processing, making it perfect for high-end manufacturing environments.

The versatility of the CKD laser glass cutting machines extends to various scenarios such as the production of tempered glass, laminated glass, and specialized colored glass cutting machine tasks. Their high positioning accuracy of ±2μm and transmission system based on rack and pinion technology enable precise and repeatable cuts, essential for industries like electronics, home appliances, and glass art design. The mobility feature, equipped with heavy-duty wheels and locking mechanisms, allows easy movement and repositioning within the workshop, enhancing operational flexibility.

Packaging is handled with utmost care through wooden vacuum packaging to ensure the machines arrive safely and intact. With a supply ability of 60 sets per month and delivery times ranging between 25-45 days, CKD meets the demands of both small-scale and large-scale manufacturers. Payment terms including L/C and T/T offer convenience and security for international buyers.

In summary, the CKD Laser Glass Cutting Machine series provides an exceptional combination of precision, durability, and adaptability. Whether you require a fiber laser cutting machine for industrial glass processing or a colored glass cutting machine for artistic applications, CKD’s product line, including models such as CKD-SP6070S-50E and CKD-DP6070D-80E, is engineered to deliver outstanding performance and reliability in diverse glass cutting occasions and scenarios.

Customization:

CKD offers a range of High Precision Laser Cutting Machines, including models CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E. These Environmental protection glass laser cutting machines are manufactured in China and hold ISO and CE certifications, ensuring high quality and compliance with international standards.

Our Laser Glass Cutting Machines deliver cutting precision up to ±0.01mm, capable of handling cutting thicknesses from 0.03mm to 25mm. With an acceleration of 1G and compatibility with popular CAD/CAM software such as AutoCAD, SolidWorks, and CorelDRAW, the machines offer an easy-to-use interface and broad programming support for efficient and precise operations.

Customization services are available to tailor the High Precision Laser Cutting Machine to your specific requirements, including options for table size, laser power up to 500W, and special cutting heads designed for curved or micro-level cutting tasks. This ensures that each machine can meet unique cutting needs effectively.

Our minimum order quantity is 1 unit, with prices negotiated based on customization and order specifics. Each machine is securely packaged using wooden vacuum packaging to ensure safe delivery. Delivery time ranges from 25 to 45 days, supported by flexible payment terms including L/C and T/T. We maintain a supply ability of 60 sets per month to meet your demand promptly.

Support and Services:

Our Laser Glass Cutting Machine is designed to provide precision cutting for various types of glass with high efficiency and minimal waste. To ensure optimal performance, please follow the recommended maintenance schedule and use only approved replacement parts.

For installation, ensure the machine is set up on a stable, level surface with adequate ventilation. Connect the laser power supply according to the specifications outlined in the user manual. Always wear appropriate safety gear when operating the machine.

Regularly clean the laser lens and mirrors to maintain cutting accuracy. Inspect the machine components for wear and tear, and replace any damaged parts promptly to avoid operational issues.

Software updates and calibration services are available to enhance machine functionality and cutting precision. We recommend periodic calibration to maintain the highest quality standards.

If you experience any technical difficulties or require assistance with operation, please refer to the troubleshooting section of the user manual. For further support, professional service technicians are available to provide onsite or remote assistance.

Training services are offered to help operators understand machine functions and safety procedures, ensuring efficient and safe operation of the Laser Glass Cutting Machine.

We are committed to providing comprehensive support and services to maximize the productivity and lifespan of your Laser Glass Cutting Machine.

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is securely packed using high-quality, durable materials to ensure safe transportation. The machine is first covered with protective foam padding to prevent any scratches or damage during handling. It is then placed inside a sturdy wooden crate, which provides additional protection against impacts and vibrations. The crate is reinforced with metal straps and labeled with handling instructions such as “Fragile” and “This Side Up” to ensure careful handling. All accessories and components are packed separately in labeled boxes within the crate to avoid any loss or damage.

Shipping:

We offer reliable shipping options to deliver the Laser Glass Cutting Machine safely to your location. The shipment is arranged via trusted freight carriers experienced in handling heavy and delicate machinery. Before dispatch, the machine undergoes a thorough inspection and testing to ensure it arrives in perfect working condition. Tracking information is provided so you can monitor the shipment status in real-time. Upon delivery, please inspect the packaging and machine for any visible damage and report immediately if any issues are found. Installation and operational support can be provided upon request to facilitate smooth setup at your facility.![]()