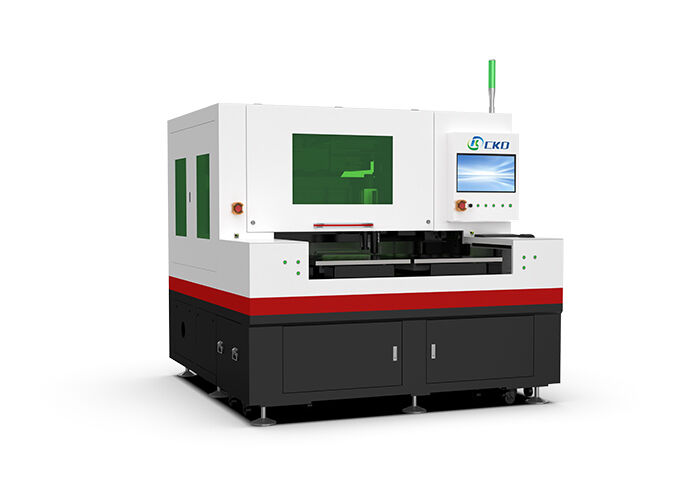

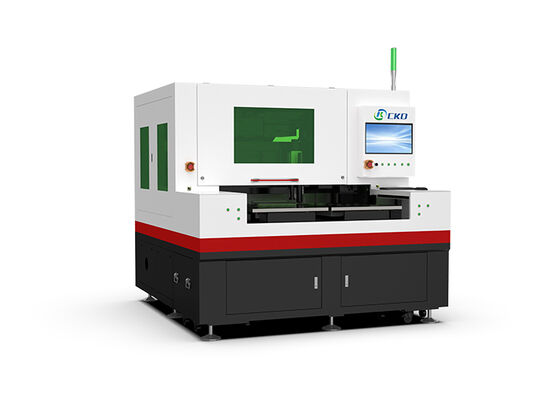

Laser Glass Cutting Machine suitable for cutting large glass panels with uniform and minimal distortion across the surface To Accuracy±0.01mm

-

Highlight

high precision laser glass cutter

,large panel glass cutting machine

,low distortion laser glass cutter

-

Splitting Laser SourceRFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W (options: 250W/350W) - 150W(250W/350W) 1-100kHz Water Cooling

-

Positioning Accuracy±2μm

-

Noise LevelOperating Noise Level Is 70dB, With A Built-in Silencing System, Suitable For Low-noise Environments.

-

Drive MotorXY Linear Motor + Grating Ruler

-

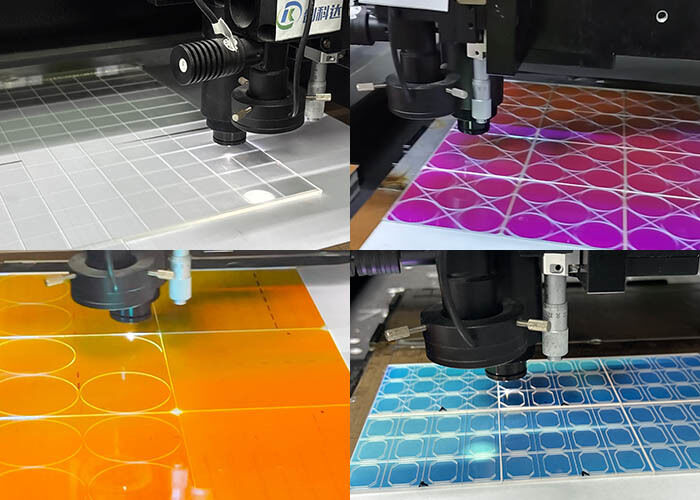

AdvantagesIrregular-shape High-speed Cutting High Cutting Quality, No Taper, No Burr, Small Chipping High Yield Rate, Low Consumables And Energy-saving No Pollution, No Powder, And No Wastewater

-

Splitting Laser Source Cooling MethodWater Cooling

-

Maintenance RequirementsRecommend Optical Alignment Every 200 Hours, And Coolant Replacement Every 1000 Hours. Regular Remote Diagnostics And Software Updates Available.

-

Cutting SpeedAdjustable From 0-500mm/s

-

Laser TypeCO2 Laser / Fiber Laser

-

SoftwareCypcut Laser Cutting System

-

Operating EnvironmentAround 26 Degrees Celsius

-

Overall Dimensions4500mm*2500mm*1500mm

-

Speed0-500mm/s

-

Laser Wavelength10.6um

-

Thickness0.03-25mm

-

Laser80W

-

Graphic FormatPLT/DXF/BMP/JPG/GIF/PNG/TIF

-

MaterialsGlass, Acrylic, Metal, Etc.

-

Cutting Accuracy±0.1 Mm

-

VoltageAC 220V/380V

-

Laser Source BrandRAYCUS

-

Machine Size2100mm*1600mm*1200mm

-

Working Voltage220V/380V

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Laser Glass Cutting Machine suitable for cutting large glass panels with uniform and minimal distortion across the surface To Accuracy±0.01mm

Product Description:

This device is an apparatus for efficient cutting of glass by high-energy laser, where the cutting is for profile machining, and CO₂ laser-assisted cracking used to achieve the cutting and cracking of glass.

The cutting accuracy is as high as ± 0.1mm, and the edge breakage is controlled within 5 microns. It supports high-speed cutting of irregular shapes, with smooth and flat cutting edges, no burrs, and small breakage, without the need for subsequent grinding, polishing, and other processing steps.

![]()

![]()

| Cutting Accuracy | ±0.01mm |

| Cutting Precision | ±0.01mm |

| Applicable Materials | Ultra Clear Glass, Plain White Glass, High Borosilicate Glass, Quartz Glass, Optical Glass, Cover Glass, Camera Glass Cover, Phone Glass Cover, Car Glass, LCD Screen, K9 Glass, Filter Cutting, Mirror Cutting, etc. |

| Key Selling Points | Ultra Fast Picosecond |

| Pulse Width | <10ps |

| Laser Type | Infrared Picosecond |

| Voltage & Power | <8KW, AC220V |

| Minimum Cutting Burr | ≤5um |

| Splitting Laser Source Laser Type | RFC02 (Radio Frequency CO2) |

| Cooling System | Water Cooling |

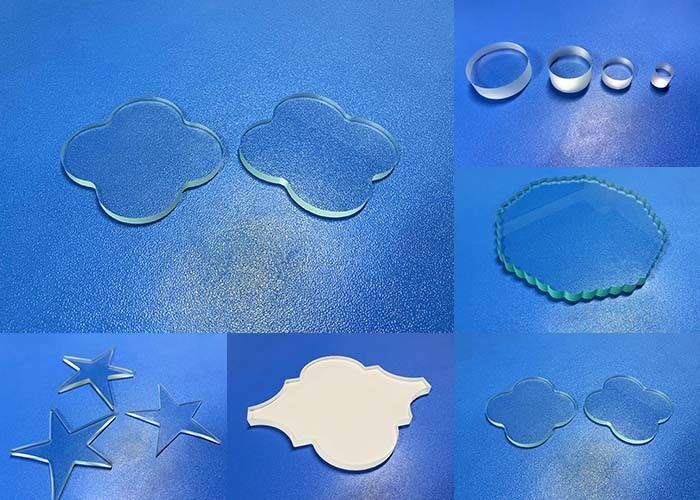

Applications:

Can process "ultra-clear glass, regular white glass, high boron silicate glass, quartz stone glass", etc., mobile phone cover, car glass cover, camera glass cover, etc., mobile phone sapphire cover, camera sapphire cover, sapphire light strip, K9 glass, filter film cutting, reflector cutting, etc. Optical glass.

![]()

![]()

Introduction to the company:

Shenzhen CKD Precision Mechanical & Electrical Co., Ltd. was established in 2010. lt is a Ultrafast laser equipment manufacturer and automation new intelligent manufacturing solution provider that integrates R&D, production, sales, and service. After more than ten years of deep cultivation and accumulation, the company has accumulated more than 70 patents, passed CE certification,1S09001 quality management system certification, and Intellectual Property Management System Certification. lt is a national high-tech enterprise and a Shenzhen Professional, Refined, Special, and Innovation Enterprise.

The company has a sheet metal workshop, machining workshop, assembly workshop, and process development and debugging workshop, covering R&D, Production, Testing, Sale & after service.

Up to now, the company has strong R&D team that has been engaged in laser structural design and laser application technology for many years. With a strong R&D ability and core software technology, the company has achieved innovation and break-through in product technology in fields such as ultra fast laser cutting, laser drilling, TFT-LCD screen laser repair, semiconductor plastic sealing and debonding, diamond grinding, laser welding, and laser marking. Especially in the processing of hard and brittle materials such as glass and ceramics, TFT-LCD repair, semiconductor plastic sealing and debonding, as well as diamond grinding and other automated new intelligent manufacturing, we provide cus- tomers with low-cost, high-quality, and high-efficiency solutions,making contributions to customer with value-added,innovation,and development.

![]()

![]()

![]()

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is carefully packed to ensure safe delivery. The machine is first covered with protective foam and plastic wrap to prevent any scratches or damage during transit. It is then placed inside a sturdy wooden crate that provides excellent protection against shocks and vibrations. All accessories and components are securely packed in separate compartments within the crate to avoid movement. Clear labeling and handling instructions are marked on the packaging to ensure proper care during shipping.

Shipping:

We offer reliable shipping options worldwide for the Laser Glass Cutting Machine. The packaging is designed to withstand long-distance transportation by sea, air, or land. Before shipping, the machine undergoes a thorough inspection to ensure it is in perfect working condition. Customers will receive tracking information once the shipment is dispatched. Our logistics partners handle the delivery with care, and we provide support for customs clearance and documentation if needed to ensure a smooth delivery process.

![]()