Laser Glass Cutting Machine providing easy integration with CAD software enabling precise programming of cutting patterns To Accuracy±0.01mm

-

Cooling SystemWater Cooling

-

AdvantagesIrregular-shape High-speed Cutting High Cutting Quality, No Taper, No Burr, Small Chipping High Yield Rate, Low Consumables And Energy-saving No Pollution, No Powder, And No Wastewater

-

Control SystemHTI Control

-

Maintenance RequirementsRecommend Optical Alignment Every 200 Hours, And Coolant Replacement Every 1000 Hours. Regular Remote Diagnostics And Software Updates Available.

-

Laser Power30/50/60/75/80/90w

-

Compatibility With Automation SystemsSupports Integration With Major Automation Systems, Including Robot Interfaces And Automatic Loading/unloading Systems. Standard Industrial Communication Protocols (like Modbus, OPC) Are Supported.

-

MaterialGlass

-

Cutting Thickness0.03~25mm

-

Cutting TechnologyLaser

-

Machine Weight2000KG

-

Graphic FormatPLT/DXF/BMP/JPG/GIF/PNG/TIF

-

Supported File FormatsPLT, DXF, BMP, AI, DST

-

Machinery Efficiency0-500mm/s

-

Cuttingaccuracy±0.01 Mm

-

Cutting Width0.03-25mm

-

SoftwareCypCut

-

Cutting SpeedUp To 3000 Mm/min

-

Linear Guide BrandTPI

-

Driving SystemHTI

-

Power Consumption≤12KW

-

Speed0-500mm/s

-

Chipping≤5μm

-

Laser80W

-

NaneGlass Laser Cutting Machine

-

Safety ProtectionHigh Safety

-

Working TableHoneycomb/Aluminum Blade

-

Control SoftwareCypcut

-

MachineweightApproximately 150 Kg

-

ProductnameLaser Glass Cutting Machine

-

Product TypeGlass Cutting Machine

-

Cutting MethodLaser Cutting

-

Thickness0.03-25mm

-

Accuracy±0.01mm

-

Wavelength Coverage1064nm

-

Cutting Size40*50cm*2

-

Supported MaterialsGlass, Tempered Glass, Laminated Glass

-

Overall Dimensions4500mm*2500mm*1500mm

-

Drive MotorXY Linear Motor + Grating Ruler

-

Work Size800*1000mm

-

Cut Speed0-500mm/s

-

Type Of CoolingWater-cooling

-

Laser Wavelength10.6um

-

Cutting Thickness0.5mm - 30mm

-

Power90W

-

Service LifeLong Life

-

ControlsystemCNC Controller

-

Acceleration1G

-

Machine Size1700mm*1700mm*1960mm

-

Whether CncYes

-

Laserpower100W - 500W

-

Working Environment26℃

-

Repeatability±1.5um

-

ProductGlass Laser Cutting Machine

-

CuttingtechnologyLaser

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

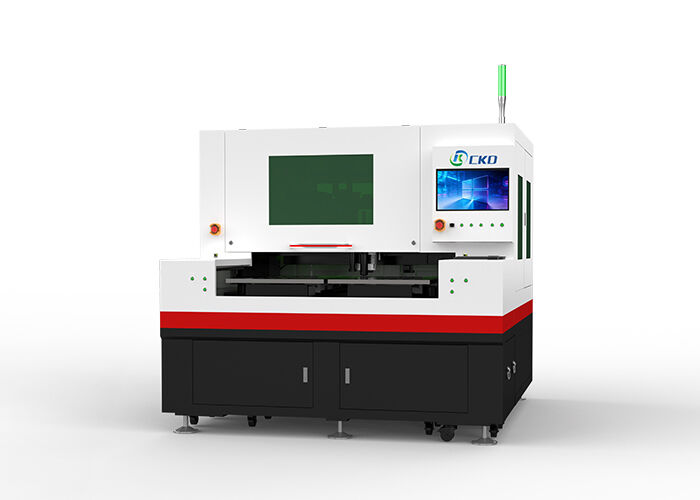

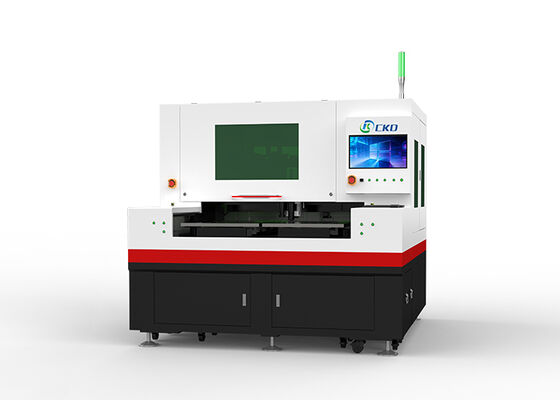

Laser Glass Cutting Machine providing easy integration with CAD software enabling precise programming of cutting patterns To Accuracy±0.01mm

Product Description:

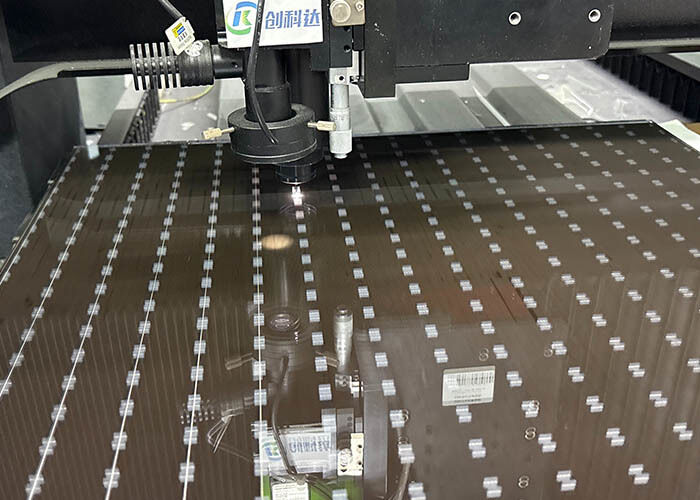

This device is an apparatus for efficient cutting of glass by high-energy laser, where the cutting is for profile machining, and CO₂ laser-assisted cracking used to achieve the cutting and cracking of glass.

Adopting laser non-contact precision cutting technology, effectively reducing the influence of stress and ensuring the quality of finished products. The equipment is equipped with an automatic positioning recognition system to achieve faster and more accurate alignment and cutting, significantly improving overall production efficiency. Cutting edges are neat and delicate, with high precision, no broken edges, and no burrs, suitable for various glass cutting and processing needs.

![]()

![]()

![]()

Technical Parameters:

| Splitting Laser Source | RFC02 (Radio Frequency CO2) - RFC02 10.6μm 150W (options: 250W/350W) - 150W(250W/350W) 1-100kHz Water Cooling |

| Weight | 3500kg |

| Cutting Precision | ±0.01mm |

| Splitting Laser Source Cooling Method | Water Cooling |

| Material | Glass |

| Positioning Accuracy | ±2μm |

| Environmental Conditions | Works Best In Temperatures Between 15°C And 30°C, With 20%-80% Relative Humidity, Suitable For Cleanrooms Or Industrial Environments |

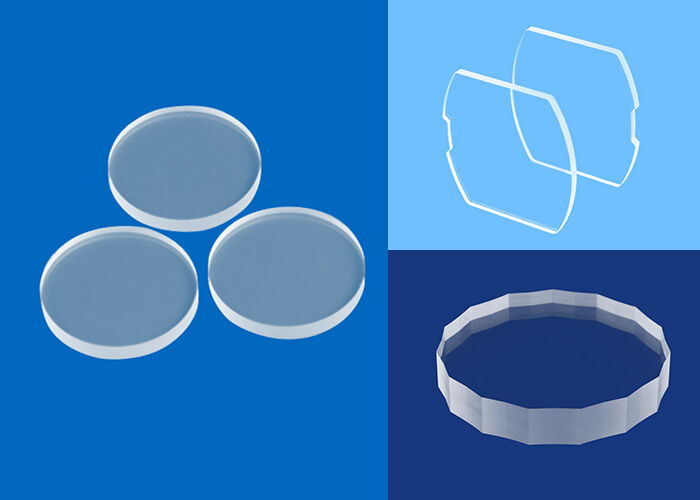

| Applicable Materials | Ultra Clear Glass, Plain White Glass, High Borosilicate Glass, Quartz Glass, Optical Glass, Cover Glass, Camera Glass Cover, Phone Glass Cover, Car Glass, LCD Screen, K9 Glass, Filter Cutting, Mirror Cutting, Etc. |

| Linear Speed | Up To 1000mm/s |

| Splitting Laser Source Laser Type | RFC02 (Radio Frequency CO2) |

Applications:

Can process "ultra-clear glass, regular white glass, high boron silicate glass, quartz stone glass", etc., mobile phone cover, car glass cover, camera glass cover, etc., mobile phone sapphire cover, camera sapphire cover, sapphire light strip, K9 glass, filter film cutting, reflector cutting, etc. Optical glass.

![]()

![]()

Introduction to the company:

Shenzhen CKD Precision Mechanical & Electrical Co., Ltd. was established in 2010. lt is a Ultrafast laser equipment manufacturer and automation new intelligent manufacturing solution provider that integrates R&D, production, sales, and service. After more than ten years of deep cultivation and accumulation, the company has accumulated more than 70 patents, passed CE certification,1S09001 quality management system certification, and Intellectual Property Management System Certification. lt is a national high-tech enterprise and a Shenzhen Professional, Refined, Special, and Innovation Enterprise.

The company has a sheet metal workshop, machining workshop, assembly workshop, and process development and debugging workshop, covering R&D, Production, Testing, Sale & after service.

Up to now, the company has strong R&D team that has been engaged in laser structural design and laser application technology for many years. With a strong R&D ability and core software technology, the company has achieved innovation and break-through in product technology in fields such as ultra fast laser cutting, laser drilling, TFT-LCD screen laser repair, semiconductor plastic sealing and debonding, diamond grinding, laser welding, and laser marking. Especially in the processing of hard and brittle materials such as glass and ceramics, TFT-LCD repair, semiconductor plastic sealing and debonding, as well as diamond grinding and other automated new intelligent manufacturing, we provide cus- tomers with low-cost, high-quality, and high-efficiency solutions,making contributions to customer with value-added,innovation,and development.

![]()

![]()

![]()

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is carefully packaged to ensure safe delivery and protection during transit. The machine is first wrapped with anti-static foam and protective film to prevent scratches and dust accumulation. It is then securely placed in a sturdy wooden crate with internal cushioning to absorb shocks and vibrations. All fragile components are individually boxed and labeled. The packaging is designed to withstand long-distance shipping and handling, ensuring the product arrives in perfect condition.

Shipping:

We offer reliable shipping options for the Laser Glass Cutting Machine worldwide. The product can be shipped via sea freight, air freight, or express courier depending on the customer’s preference and destination. Before shipping, the machine undergoes thorough inspection and testing to guarantee quality standards. Tracking information will be provided once the shipment is dispatched. We also assist with customs clearance and provide all necessary documentation to ensure a smooth delivery process.

![]()