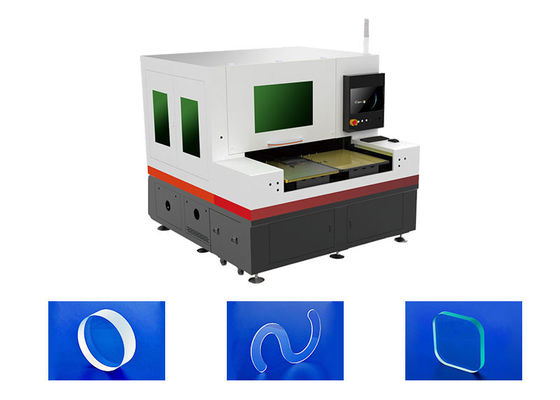

Infrared Picosecond Dual-Table

Laser Cutting Machine For Optical Mirrors

The Infrared Picosecond Glass Cutting & Splitting Machine is a state-of-the-art technology that offers unparalleled cutting capabilities. Its ability to perform irregular-shape high-speed cutting, deliver high cutting quality, and offer cost savings and environmental benefits make it a top choice for glass cutting applications. Whether you are working on artistic glass projects or industrial glass cutting, this machine will exceed your expectations. Say goodbye to manual labor and outdated cutting methods, and say hello to efficiency, precision, and cost-effectiveness with the Infrared Picosecond Glass Cutting & Splitting Machine.

Product Advantages

1. The light source is a high-power picosecond laser.

3. Self-developed glass cutting head, lens all imported, light spot fine, deep focus;

3. Support cutting segments in one, separate cutting, separate segments;

4. X/Y axis motor adopts high-end linear motor, Germany 0.1um digital grating ruler;

5. Motion control standard PSO function, uniform control of laser spot spacing;

6. The device aligns CCD and telecentric vision lens to accurately identify mark points such as circle and cross.

7. The electrical components are made by Schneider of France, and the switching power supply is made by Taiwan Mingwei.

8. One time can be cut within 19mm thickness;

9. Motor platform, optical platform base using natural marble, accuracy is more guaranteed;

Technical Parameter

| Cutting laser source |

| Laser type |

Infrared picosecond pulsed laser |

| power |

50W(optional 10W, 20W, 30W, 60W, 80W, etc.) |

| Wave length |

1064nm, beam quality :M2<1.2 |

| Pulse width |

<10PS; Pulse frequency :1Hz-1000kHz |

| Cooling mode |

water-cooling |

| Cutting performance |

| Drive motor |

XY linear motor + grating ruler |

| Cutting speed |

0-500mm/s adjustable |

| Cutting thickness |

Ultra white glass knife ≤19mm |

| Minimum cutting edge breakage |

5um |

| Cutting accuracy |

≤20um |

| Voltage, power |

<5KW,AC220V |

| Equipment size |

1700mmX1700mmX1960mm |

| weight |

2000KG |

| Ground load |

>500-700kg/m² |

Details Images

1.Picosecond infrared ultra-fast laser source

2.High-precision Moving Components

3.Fully Automated Asynchronous Intelligent loading And Unloading Structure

4.CCD Camera Automatic Positioning

FAQ

Q1. I don't know anything about this machine, what kind of machine should I choose?

Very easy to choose. Just tell us what you want to do with a picosecond glass cutter and let us provide

Q2. When I got this machine, I didn't know how to use it. what do l do?

We will send video and English manual to the machine. lf you still have questions, we can chat by phone

Q3 . What should I do if the machine has a problem during the warranty period?

If there is a problem with the machine, we will repair it for free during the machine warranty period. So if

Q4. Before asking me about our fiber lasers, you'd better provide me with the following information

1) Your material size. Because in our factory, we have different models according to the

work area.

2) Your material.

Metal/Acrylic/Plywood/MDF/Glass?

3) Do you want to engrave or cut?

If cutting, can you tell me the thickness of your cut? Because different cutting thicknesses require different

laser tube power and laser power suppliers.