Introduction:

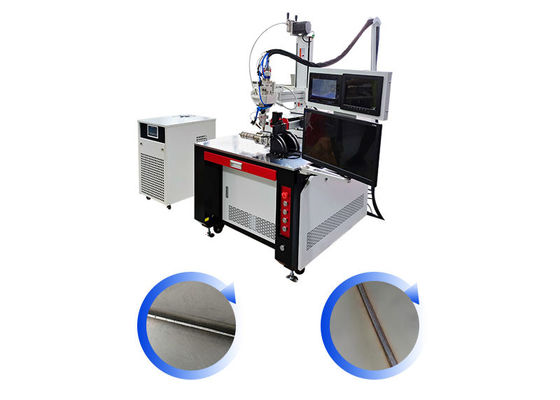

The welding machine is used the galvanometer as the control system of the laser beam. Oscillated scanning lens is used instead of moving the workpiece or working table, less time welding in the scanning range. The greater distance between the points, more number of marking points on the workpiece and give more advantages. The efficiency is 4-10 times more than ordinary laser welding; Using high-precision optical system to ensure the consistency of each welding spot; Computer controlled systems and use windows based software which easier to operate.

Working scope:

Suitable for welding connecting pieces of new energy lithium battery packs.

Can weld aluminum-aluminum, aluminum-copper, copper-copper and other materials.

Suitable for welding connecting pieces, tabs, poles, explosion-proof valves, bus bars, etc.

Features:

1. Using the British imported ceramic condenser, high corrosion resistance, high temperature resistance, for 8-10 years life.

2. HD CCD monitoring system, the welding condition is clearly visible to avoid outflow of defective products.

3. The energy distribution of welding spot is uniform, with the best spot needed for welding characteristics.

4. Servo drive workbench speed is 2-3 times of 0.02mm, escort for precision machining.

5. Laser welding can be used for spot welding, butt welding, overlay welding and sealing welding of thin-walled materials and precision parts.

6. It can customize special automatic chemical fixture to realize mass production of products.

Laser machine specifications

|

1

|

Laser power

|

500W 1000W 1500W 2000W 3000W

|

|

2

|

Laser wavelength

|

1064 nm

|

|

3

|

Monopulse Power

|

90j-150j

|

|

4

|

Depth of laser welding

|

0.1-2.0 mm

|

|

5

|

Power consumption

|

≤13KW

|

|

6

|

Electricity demand

|

220V ± 10%/50Hz/30A

|

|

7

|

Pulse width

|

0.3-20ms

|

|

8

|

Laser welding frequency

|

1-100Hz

|

|

9

|

Adjustable spot size range

|

0.2-2 mm

|

|

10

|

Repeatability

|

± 0.01 mm

|

The CKD CW-A1 Mold Repair Laser Welding Machine is the perfect solution for all your mold repair and welding needs. With its advanced Laser Welding Technology, it provides superior welding characteristics, ensuring high-precision and fast welding. Its dust-free working environment ensures a safe and clean working environment. The CW-A1 is the perfect choice for industries that require high-precision welding and mold repair.

At XYZ Company, our team of experts is dedicated to providing you with best-in-class technical support and service for Automatic Laser Welding Machine. We provide a full range of services, from installation and training to maintenance and repair.

Our team of engineers and technicians can provide installation and training for Automatic Laser Welding Machine. We can install the machines in your facility and provide on-site training to ensure that you and your staff understand how to use the machine properly and safely.

Our team can also provide comprehensive maintenance and repair services for Automatic Laser Welding Machine. We have parts in stock and can provide a rapid response to any issues that may arise. We also offer preventive maintenance services to ensure the long-term reliability of the machine.

We have a dedicated customer support team available to answer any questions or provide assistance with Automatic Laser Welding Machine. Our team can be reached by phone, email, or through our website. We also offer remote support services for troubleshooting and diagnostics.

Q1: Could I visit your factory?

A1: Yes, We will warmly welcome you anytime. It's tooks about 1 hours from Bao'an International airport to our factory.

Q2: How many years do you do this business?

A2: From 2008.

Q3: Does your factory have the design & development capacities, we need customized products?

A3: yes. The staffs in our design department are well experienced in laser machine, with more than 5 to 10 years experience.

We can make customized products especially for you; Please kindly contact us for more details.

Q4: What is payment terms?

A4: 100% T/T advanced.

Q5: About shiping?

A5: 3-10 days after payment for standard products, please consult our sales for customized products.

Q6: How about your after service?

A6: Our engineers who has long time professional experience and sales will help you within 24h.

Q7: Do you have patents or core technology?

A7: Yes, for details, please contact our sales.

Q8: Where have you sold your products?

A8: Europe, Americas, Africa, and Asia.