Working Environment 26C Polygonal

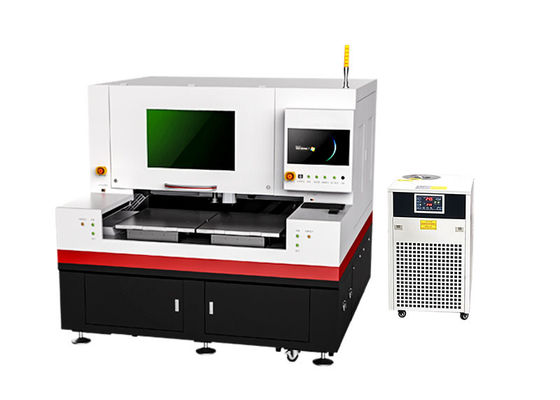

Glass Cutting Machine All-in-One

Product Description:

The Laser Glass Cutting Machine is a single table glass cutting machine that is ideal for small glass laser cutting projects. It is suitable for working environments with a temperature of 26℃, and is powered by 220V and a frequency of 50HZ/60HZ. This machine is equipped with a water cooling system to ensure reliable, ultra fast picesecond cutting performance. It is an easy-to-use, cost-effective solution for the most demanding laser glass cutting projects. The Laser Glass Cutting Machine is the perfect choice for any business looking for a reliable and affordable laser glass cutting solution.

| Significant attribute | |

| X/Y movement speed | max. 500mm/s |

| Laser type | Infrared picosecond |

| Laser wavelength | 1064nm |

| Laser power | 10W/20W/40W/70W/80W optional |

| Pulse length | ≤10PS |

| Pulse frequency | 1Hz-1000kHz |

| Working mode | Laser XY moving |

| Cooling method | Water-cooled |

| Focusing mode | Cutting head |

| Focusing spot | ≤Ф3um |

| Cutting speed | Adjustable 0-500mm / s |

| Cutting thickness | according to the thickness of the glass to choose the number of laser W |

| Minimum cutting edge chipping | 6um |

| X / Y cutting stroke | 400mm x500mm (600X700mm 600X900 optional or customize a larger platform) |

| X/Y positioning accuracy | ≤±2μm |

| X/Y repeat positioning accuracy | ≤±1um |

![]()

Strengthened and non-strengthened glass cutting (mobile phone glass cover, car glass cover, camera glass cover, etc.), sapphire glass cutting (mobile phone sapphire cover, camera sapphire glass cover, sapphire light bar (LED light bar), etc.),

LCD glass cutting (abnormal LCD screen inverted R/U/C angle, LCD screen slitting, etc.),

other optical glass cutting (filter cutting, mirror cutting, etc., prisms, etc.),

*After placing an order, the delivery lead time is usually within 15-30 working day

Applied Range

Instruments, thick, extra thick glass industry cutting, such as: ultra white glass, white glass, high borosilicate glass, quartz glass, etc.;Reinforced and non-reinforced glass cutting, such as: mobile phone glass cover plate, car glass cover plate, camera glass cover plate, etc.;Sapphire glass cutting, such as: mobile sapphire cover plate, camera sapphire glass cover plate, sapphire light strip (LED light strip), etc.LCD glass cutting, such as: shaped LCD screen inverted R/U/C Angle, LCD screen cutting, etc.Other optical glass cutting, such as :K9 glass, filter cutting, mirror cutting, etc.

Customization

This machine can be used for 0.1mm-6mm reinforced and non reinforced glass cutting, such as mobile phone glass cover, car glass cover and camera glass cover. 0.1mm-2mm sapphire glass cutting, such as: mobile phone sapphire cover,camera sapphire glass cover, sapphire lamp post(LED lamp post).LCD glass cutting and other optical lens cutting.processing.

According to the needs of customers, the laser cutting machine is designed to meet the requirements. Including the selection of the appropriate laser source, optical path system, motion control system, appearance size, etc

Technical Support and Service for Laser Glass Cutting Machine

We provide a comprehensive technical support and service for our Laser Glass Cutting Machine. We are here to help you with any technical questions or issues you may have.

Our team of experienced engineers and technicians are available to provide assistance with installation, troubleshooting, and general maintenance. We offer a dedicated customer service line where you can reach us anytime, day or night.

We also provide a full range of spare parts for our Laser Glass Cutting Machine. All of our parts are sourced directly from the manufacturer, giving you the peace of mind that you are receiving genuine and reliable components.

We are committed to providing the best service and support for our customers and we take pride in the quality of our products. If you have any questions or concerns, please do not hesitate to contact us.

The Laser Glass Cutting Machine is packaged in a custom-made box and shipped with a special foam insert to ensure maximum protection during transit.

The box is reinforced with extra layers of cardboard for extra strength and durability. The foam insert is designed to fit the Laser Glass Cutting Machine securely and reduce the possibility of damage during transit.

The box is labeled with the model number, machine serial number, and shipping address before being shipped.

Q1: I don't know anything about this machine, what kind of machine should I choose?

Very easy to choose. Just tell us what you want to do with a picosecond glass cutter and let us provide you with the perfect solution and advice.

Q2: When I got this machine, I didn't know how to use it. what do I do?

We will send video and English manual to the machine. If you still have questions, we can chat by phone or via Skype and email.

Q3: What should I do if the machine has a problem during the warranty period?

If there is a problem with the machine, we will repair it for free during the machine warranty period. So if you have any questions, please let us know and we will provide you with a solution.

Q4: Before asking me about our fiber lasers, you'd better provide me with the following information

1) Your metal or non-metal material size. Because in our factory, we have different models according to the work area.

2) Your material.

Metal/Acrylic/Plywood/MDF/Glass?

3) Do you want to engrave or cut?

If cutting, can you tell me the thickness of your cut? Because different cutting thicknesses require different laser tube power and laser power suppliers.