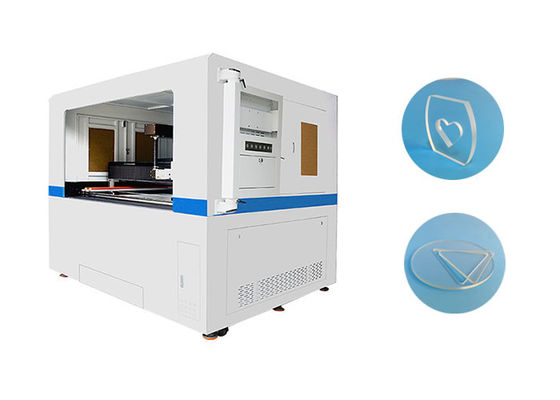

Laser glass drilling machines typically use laser processing systems equipped with high-precision optical lenses and control systems to achieve precise hole drilling of glass materials.

These are generally suitable for the processing of items made out of glass, optical glass, and devices made of glass. The machines are capable of drilling precision holes, such as round holes to slot holes, with accuracy.

| Technical parameters | |

| Laser type | Fiber Mopa |

| Laser power | 120w / 180w |

| laser wavelength | 532nm |

| laser pulse width | 7ns@100KHz |

| Laser pulse frequency | 50-500KHz |

| Work Size | 800*800mm / 600*900mm |

| Drilling Thickness | <20mm |

| Drilling Φ | <Φ100mm |

| Positioning Accuracy | ±0.02mm |

| Chipping | ≤200μm |

| Positional accuracy | ±3μm / ±5μm |

| Power | AC220V±5%,L+N+E,<3KW |

| Dimension | 1560mm × 1750mm × 1750mm / 1900mm ×1800mm × 1900mm |

| Weight | 1500kg |

Laser glass drilling machine has many advantages as the processing technology using laser technology.

One of the advantages is its precision. The machine can provide high-level precision when processing tiny size holes, It is able to meet the requirements of high precision glass production.

The processing itself is also a non-contact process. With the laser beams used, itl avoids the problem of surface damage and cracking that may occur from traditional mechanical processing methods, which ensures the quality fo the products.

This machine also offers high efficiency. It is able to quickly and accurately complete the hole processing of glass materials. This will improve the production efficiency while reducing the cost of production.

One more impressive part of this machine is the flexibility it offers. It is capable of process a variety of hole shapes, such as round and slot holes, as well as its strong processing capabilities.

Finally, most laser glass drilling machines are equipped with a numerical control system, which can enable the automatic control of the process. This results in improved consistency and stability during the processing time.

The laser glass drilling machine is a powerful tool for performing all kinds of glassware manufacturing and processing. It offers great versatility in creating nozzle holes, handle holes, and other precision hole processing of glassware such as glass glasses, glass bowls, glass bottles, optical glass, glass rods, glass tubes, and glass crafts. This machine can also be used for the production of optical devices like laser lenses, optical filters, and other precision contour processing.

The machine is specifically designed to deliver accuracy and efficiency in manufacturing processes, whether it is for glassware, optical glass, glass devices, glass crafts, or optical devices. With its advanced laser drilling technology, it can accurately create holes and cuts on any glass and optical material with remarkable strength and precision. It is also capable of carrying out decorative processing of glass craft items like pendants, jewelry, and other ornamentals.

The laser glass drilling machine is a highly reliable and efficient tool that is ideal for a range of glass manufacturing and processing needs. With its state of the art technology, it is capable of meeting accuracy requirements for any application, which makes it an indispensable resource for anyGlass Works.

Laser Drilling Machine Technical Support and Service

We offer technical support and service for our Laser Drilling Machine. Our technical support team provides remote and on-site service and repair, as well as maintenance and troubleshooting for our products. Our team is available to answer your questions and address any issues you may have with our products.

We provide a range of services to keep our products running smoothly, including:

If you need help with our Laser Drilling Machine, please contact us and we’ll be happy to assist.

The packaging and shipping of the Laser Drilling Machine should meet the following requirements: