The laser glass drilling machines usually come equiped with laser processing systems, control systems and precision optical lenses for precision hole processing of glass materials.

These laser drilling machine are widely used in the production of glassware, glass devices, optical glass and other fields and can bring accurate round holes, slot holes and other shapes of holes in glass.

| Technical parameters | |

| Laser type | Fiber laser |

| Laser power | 120w / 180w |

| laser wavelength | 532nm |

| laser pulse width | 7ns@100KHz |

| Laser pulse frequency | 50-500KHz |

| Work Size | 800*800mm 800*1000mm |

| Drilling Thickness | <20mm |

| Drilling Φ | <Φ100mm |

| Positioning Accuracy | ±0.02mm |

| Chipping | ≤200μm |

| Positional accuracy | ±3μm / ±5μm |

| Power | AC220V±5%,L+N+E,<3KW |

| Dimension | 1560mm × 1750mm × 1750mm / 1900mm ×1800mm × 1900mm |

| Weight | 2000kg |

Laser glass drilling machines provide high precision when processing glass products; this is achieved through advanced laser technology which is capable of tiny size hole processing for incredibly accurate results.

In addition, this type of machinery offers non-contact procesing. Traditional mechanical processing can cause surface damage and cracks on glass products, however these issues are preventable when using a laser glass drilling machine as it uses laser beams to achieve a non-contact approach, thus ensuring a higher quality of glass products.

Furthermore, these machines are capable of achieving high efficiency, as they can quickly and accurately finish the hole processing of glass materials in a short period of time, which will increase production speed and reduce production costs.

Furthermore, the laser glass drilling machine offers flexibility, as it offers the capability of producing holes of different shapes, such as round and slot holes, making it a more diverse and multi-purpose machine.

Lastly, laser glass drilling machines are typically equipped with advanced numerical control systems allowing them to be automatically controlled, resulting in improved stability and consistency during the processing.

Glassware manufacturing: The laser glass drilling machine can provide a range of services for those engaged in glassware production, such as glasses, bowls and bottles. The holes for spouts, handles and other components can be precisely created with the machine.

Optical glass processing: The laser glass drilling machine can provide a perfect solution for high accuracy processing and production of optical glass materials needed for optical devices.

Glass device processing: The machine can also be used for the hole processing of glass rods, tubes and other devices. With high precision processing, manufacturers can achieve optimal results for their glass device production.

Glass crafts manufacturing: The laser glass drilling machine can be applied for the production of various glass pendants, jewelry and other crafts, providing the users with the possibility to finish their desired products thanks for the precise hole and decorative processing.

Optical device processing: This laser glass drilling machine is also suitable for optical device manufacturing, such as for the production of laser lenses, optical filters and other components. The precise hole and contour processing of the machine can effectively support the complex production of such items.

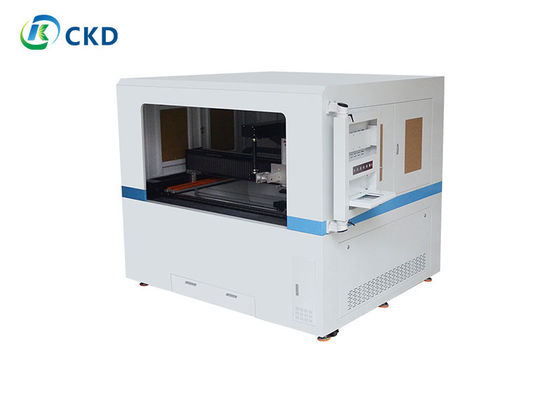

Customized services for Laser Drilling Machine – CKD CC-GM6

Brand Name: CKD

Model Number: CC-GM6

Place of Origin: China

Certification: ISO/CE/FDI

Minimum Order Quantity: 1

Price: Negotiated

Packaging Details: Wooden box

Delivery Time: 15-45 days

Payment Terms: L/C, T/T

Supply Ability: 50 sets per month

Repeatability: ±0.01mm

Pulse Width: 20ns

Laser Wavelength: 1064nm

Repetition Frequency: 20kHz

Laser Beam Mode: Green Nanosecond

Our Laser Drilling Machine – CKD CC-GM6 is the ideal choice for horizontal glass drilling machine, widely used in various industries. It boasts superior repeatability of ±0.01mm, pulse width of 20ns, laser wavelength of 1064nm, repetition frequency of 20kHz and laser beam mode of green nanosecond. Moreover, it is ISO/CE/FDI certified and can be supplied in a minimum quantity of 1 set with a delivery time of 15-45 days.

Technical support and service is available for our Laser Drilling Machine. Our dedicated team of engineers and technicians are on-hand to provide a range of services including:

Our team is available 24/7 to provide assistance with any technical issues related to the Laser Drilling Machine. We also provide a comprehensive warranty for our product.

The Laser Drilling Machine is packaged and shipped to customers with the greatest care. To ensure that the customer receives the product in perfect working condition, the following steps are taken: