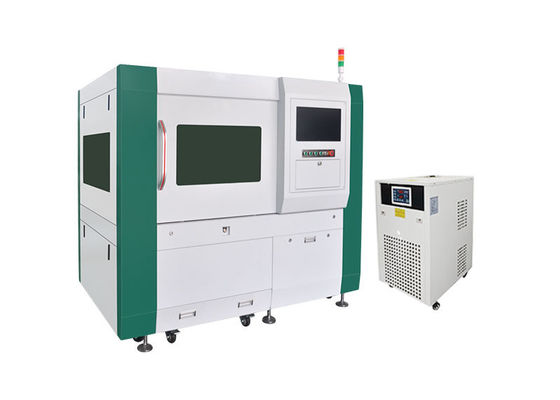

Enclosed Fiber Laser Cutting Machine

For Sheet Metal And Stainless Steel

CypCut sheet cutting software is an in-depth design for fiber laser cutting industry . It simplifies complex CNC machine operation and integrates

CAD , Nest and CAM modules in one . From drawing , nesting to workpiece cutting all can be finished by a few clicks .

1 . Auto Optimize Imported Drawing

2 . Graphical Cutting Technique Setting

3 . Flexible Production Mode

4 . Statistic of Production

5 . Precise Edge Finding

6 . Dual-Drive Error Offset

|

Model

|

6060 Metal Sheet Fiber Laser Cutting machine

|

|

Control system

|

Cypcut DSP controller

|

|

Laser Power

|

1000W 1500W 2000W 3000W

|

|

Working area

|

600*600mm

|

|

Power Consumption

|

≤12KW

|

|

Laser Wavelength

|

1080nm

|

|

Working Table

|

Sawtooth

|

|

Auxiliary Gas

|

Oxygen, Nitrogen, Air

|

|

Maximum Idle Running Speed

|

40mm/s

|

|

Working life of fiber module

|

More than 100000 hours

|

|

Fiber laser cutting head

|

Worthing/Raytools/Au3Tech

|

|

Linear guider system

|

HIWIN/PMI made in Taiwan

|

|

Transmit system

|

Ball screw

|

|

Driver system

|

FUJI servo motor

|

|

Working voltage

|

220V/380V, 50Hz/60Hz

|

|

Warranty time

|

Whole machine for 24 months

|

|

Dimension

|

1930*1650*2030mm

|

|

Gross weight

|

1500KG

|

![]()

Application Industry :

Manufacturing Billboard , Advertising , Signs , Signage , Metal Letters , LED Letters , Kitchen Ware , Advertising Letters , Sheet Metal Processing , Metals Components and Parts , Ironware , Chassis , Racks and Cabinets Processing , Metal Crafts , Metal Art Ware , Elevator Panel Cutting , Hardware , Auto Parts , Glasses Frame , Electronic Parts , Nameplates , etc.

Available Materials :

Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.

FAQ

Q1: How can I get the best machine for me?

You can tell us your working material, detail work by picture or vedio so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.