Small Size Glass Mirror Cutting Machine 50W For Car Rearview Mirror

-

Highlight

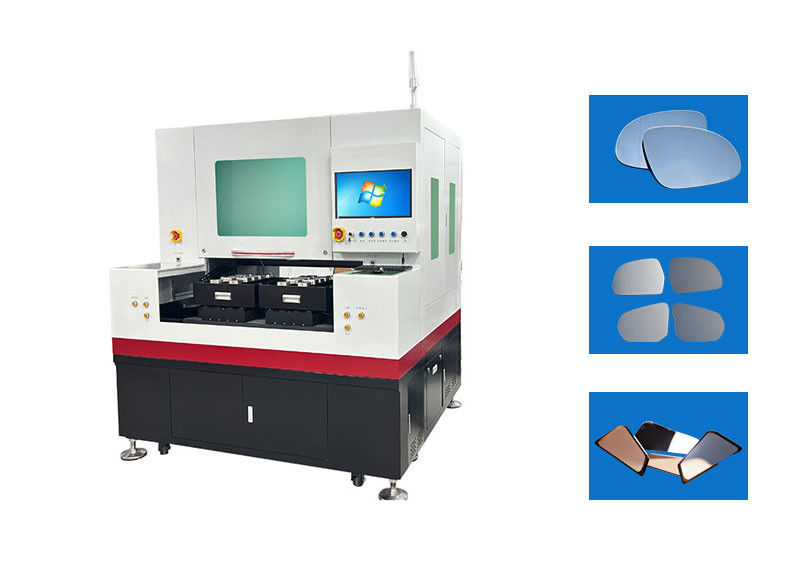

Small Size Glass Mirror Cutting Machine

,Glass Mirror Cutting Machine 50W

,Glass Laser Cutting Machine Small Size

-

NameCar Rearview Mirror Cutting Machine

-

Laser Power50W

-

Work Size20X50cmX2

-

Accuracy±0.01mm

-

Thickness≤5mm

-

Speed0-500mm/s

-

Chipping≤0.02mm

-

Laser Wavelength1064nm

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO

-

Model NumberCC-GM5

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-45 days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

-

Supply Ability50 Sets Per Month

Small Size Glass Mirror Cutting Machine 50W For Car Rearview Mirror

Infrared Picosecond 80W Glass Laser Cutting Machine

For Auto Rearview Mirror

Product Description

The laser rearview mirror glass cutting machine is an efficient and accurate cutting equipment that can be used to manufacture rearview mirror glass and other related products.

It is usually composed of laser generator, optical system, control system, cutting platform and other parts. The laser generator produces a high energy laser beam, which can be focused to a very small point after the optical system is focused, so as to achieve the cutting of the glass. The control system can adjust the cutting parameters according to the need to control the cutting speed and precision. The cutting platform is used to hold and move the glass to be cut.

Excellent in cutting glass for mirrors, light fittings, ovens, gas stoves, trophies, crafts, mobile phones, doors and windows. Can be applied to different thickness of glass round, square, polygon, irregular shaped laser cutting.

| significant attribute | |

| X/Y movement speed | max. 500mm/s |

| Laser type | Infrared picosecond |

| Laser wavelength | 1064nm |

| Laser power | 50W/80W optional |

| Pulse length | ≤10PS |

| Pulse frequency | 1Hz-1000kHz |

| Working mode | Laser XY moving |

| Cooling method | Water-cooled |

| Focusing mode | Cutting head |

| Focusing spot | ≤Ф3um |

| Cutting speed | Adjustable 0-500mm / s |

| Cutting thickness | According to the thickness of the glass to choose the number of laser W |

| Minimum cutting edge chipping | 6um |

| X / Y cutting stroke | 200mm x400mm 400mm x500mm (or customize a larger platform) |

| X/Y positioning accuracy | ≤±2μm |

| X/Y repeat positioning accuracy | ≤±1um |

![]()

Applying Materials

1. Brittle materials/strengthened and non-strengthened glass cutting:

1. Brittle materials/strengthened and non-strengthened glass cutting:

3. optical or Other glass cutting:

Sample Display

1. Shape:

2. Thickness:

SUBSEOUENT SPLIT PROCESSING

Automatic transfer to C02 splitter after cutting

C02 splitter is a device that uses C02 laser technology to cut splinters. It uses high energy C02 laser beam to cut the material, and has the characteristics of fast cutting speed, high precision and easy operation.

![]()

1 . Non-strengthened glass: CO2 laser can be used to heat along the cutting line, sothat the glass will be heated to produce stress and separate the shards / after cutting , it will be strengthened twice to produce stress shards ;

2 . Tempered glass: After cutting , the self-strengthening stress is released and thesplinters are separated automatically ;

3 . LCD screen glass: mechanical pulling , firing pin split / ultrasonic split ;

4 . Filter glass: mechanical knife lobes, etc.;

5 . Camera protection glass: laser cracking or soaking in chemical medicine , etc.

Whether the equipment needs a CO2 laser splitter , please contact ourcustomer service to confirm !

WHY CHOOSE US

Q1: 1. who are we?

A1:Established in 2010,Shenzhen CKD Precision Mechanical & Electrical Co., Ltd is a laser equipment manufacturer and automation

New Intelligent Manufacturing solution provider, specializing in the R&D, production, sales, and service.

Q2: how can we guarantee quality?

A2: our product technology has achieved innovation and breakthroughs in fields such as ultra-fast laser cutting, laser drilling, TFT-LCD screen laser repair, laser welding, and laser marking. Especially in the automation new intelligent manufacturing of glass brittle material processing and TFT-LCD repair industry, the company provides customers with low-cost, high-quality, and efficient solutions, making contributions to customer value, innovation, and development.

Q3: why should you buy from us not from other suppliers?

A3: Both wholesale and Customize design, development, New technology Real manufacture with own factory Fast reaction and top service Quick delivery High Quality standard Prompt and high quality after sale service