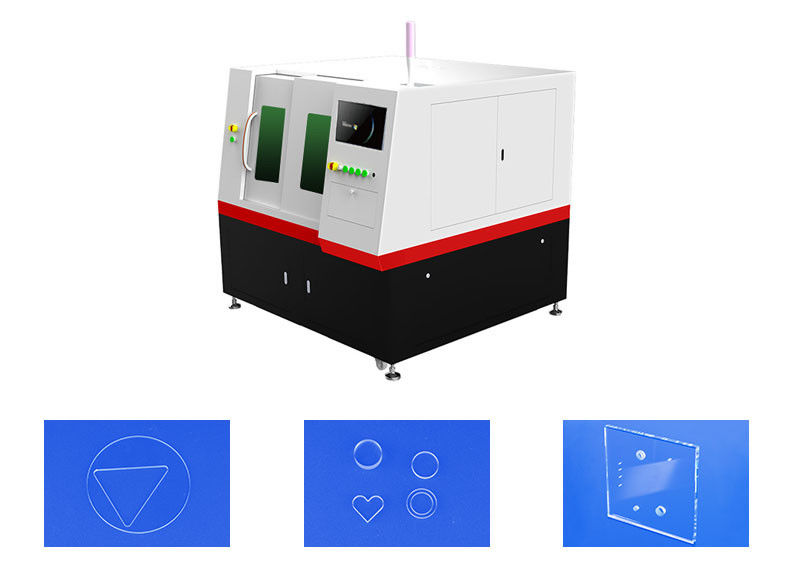

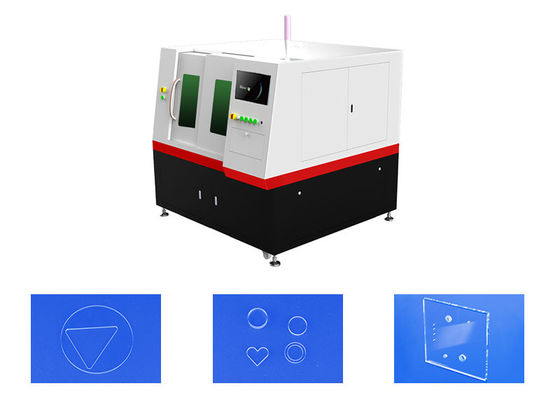

400*400mm Area Glass Laser Drilling Machine 10W 30W 45W With Green Nanosecond

-

Highlight

400*400mm Laser Drilling Machine

,Glass Laser Drilling Machine

,Glass Drilling Machine 30W

-

NameLaser Drilling Machine

-

Laser TypeGreen Pulse Laser

-

Laser Power10w , 30w , 45w

-

Laser Wavelength532nm

-

Laser Pulse Frequency50-500KHz

-

Work Size800*800mm 800*1000mm

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO / CE

-

Model NumberCC-GM3

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-45 days

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability50 Sets Per Month

400*400mm Area Glass Laser Drilling Machine 10W 30W 45W With Green Nanosecond

400*400mm Area Glass Laser Drilling Machine

With Green Nanosecond

Scope of application

This glass drilling machine uses a green nanosecond laser. Nanosecond laser pulses usually have a shorter pulse width, generally in the order of nanoseconds (10^-9 seconds), while green laser refers to the wavelength of the laser in the green spectral range, generally about 532 nanometers.

Description

1 . Fine processing capability

The pulse width of the green nanosecond laser is short, which can achieve fine processing of glass materials, such as micro-hole drilling, micro-cutting, etc., and can be applied to areas with high precision requirements in glass processing.

2 . High efficiency

The working efficiency of the green nanosecond laser is high, which can quickly complete the drilling task, improve production efficiency and save time cost.

3 . High quality

The drilling process of the green light nanosecond laser will not produce mechanical force, will not damage the glass surface, the drilling aperture is smooth, no burrs, no cracks, to ensure the quality of the drilling.

4 . Flexibility

The green nanosecond laser can drill holes of different shapes and sizes according to needs, and can achieve complex hole designs to meet different processing needs.

| Technical parameters | |

| Laser type | Green pulse laser |

| Laser power | 10w , 30w , 45w |

| laser wavelength | 532nm |

| laser pulse width | 7ns@100KHz |

| Laser pulse frequency | 50-500KHz |

| Work Size | 800*800mm 800*1000mm |

| Drilling Thickness | <20mm |

| Drilling Φ | <Φ100mm |

| Positioning Accuracy | ±0.02mm |

| Chipping | ≤200μm |

| Positional accuracy | ±3μm / ±5μm |

| Power | AC220V±5%,L+N+E,<3KW |

| Dimension | 1560mm × 1750mm × 1750mm / 1900mm ×1800mm × 1900mm |

| Weight | 1500kg |

![]()

Processing advantage

1 . Irregular/micro/through/countersunk/tapered holes

2 . Non-contact processing, Min material damage

3 . High drilling accuracy, min Chipping, wastewater-free

4 . High performance servo + precision screw + precision guide closed loop control ;

5 . High power pulse laser is used to cut glass with small edge breakage and fast speed .

6 . Using high-precision galvanometer , with telecentric lens , cutting stability , and the maximum close to no taper ;

7 . High negative pressure vacuum machine is used to adsorb products to ensure positioning stability ;

8 . Equipped with automatic alignment CCD and visual lens , can be used for alignment cutting ;

9 . Professional cutting software, easy to learn and use to meet application needs ;

|

Applicable Industries

|

||

|

Glass

Optic/UTG/Willow/Brittle/Biomedical Glass

|

Real Estate

Architectural decoration bathroom glass

|

Automobile

Car glass/Instrumentation panel

|

|

Communication Media

Mobile/Watch /Sapphire cover/ Camera/CCTV Lens

|

Home Appliance

Home appliance glass panel lighting glass

|

New Energy

Photovoltaic glass

|

![]()

FAQ

Q1: I don't know anything about this machine, what kind of machine should I choose?

Very easy to choose. Just tell us what you want to do with a picosecond glass cutter and let us provide you with the perfect solution and advice.

Q2: When I got this machine, I didn't know how to use it. what do I do?

We will send video and English manual to the machine. If you still have questions, we can chat by phone or via Skype and email.

Q3: What should I do if the machine has a problem during the warranty period?

If there is a problem with the machine, we will repair it for free during the machine warranty period. So if you have any questions, please let us know and we will provide you with a solution.

Q4: Before asking me about our fiber lasers, you'd better provide me with the following information

1) Your metal or non-metal material size. Because in our factory, we have different models according to the work area.

2) Your material.

Metal/Acrylic/Plywood/MDF/Glass?

3) Do you want to engrave or cut?

If cutting, can you tell me the thickness of your cut? Because different cutting thicknesses require different laser tube power and laser power suppliers.