3 Axis Fiber Glass Laser Drilling Machine For SCHOTT Optical Components

-

Highlight

3 Axis Laser Drilling Machine

,ISO Laser Drilling Machine

-

NameFiber Mopa Glass Drilling Machine

-

Drilling Thickness0.1-15mm

-

Positioning Accuracy±0.02mm

-

Chipping≤200μm

-

Work Size80*80cm

-

Laser Power180W

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO / CE / FDI

-

Model NumberCC-GM2

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-45 days

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability30 Sets Per Month

3 Axis Fiber Glass Laser Drilling Machine For SCHOTT Optical Components

3axis Fiber Laser Glass Drilling Machine

For SCHOTT Optical Components

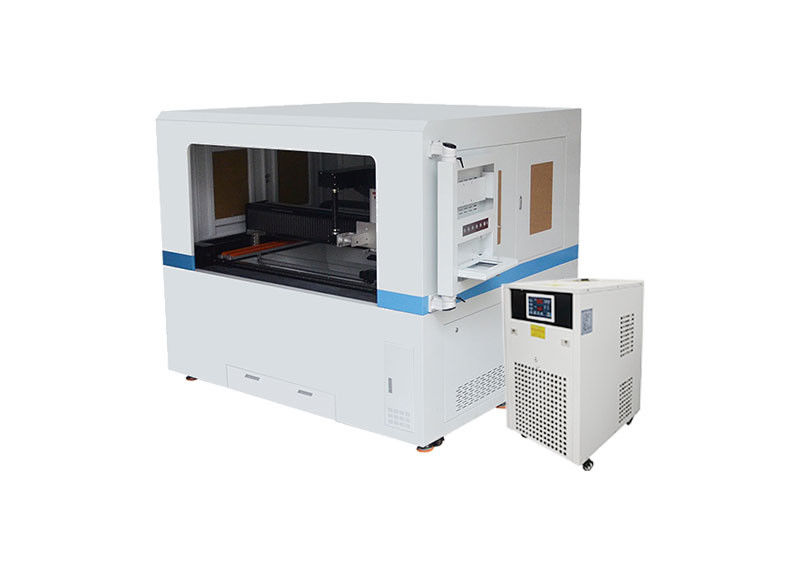

Product Description:

Infrared subnanosecond laser has been widely used in the field of microhole drilling of glass materials such as microelectronics, biomedicine and optical devices.

1. It enables fine processing of glass materials, including micro-hole drilling.

2. The heat affected area is small, and the instantaneous high energy laser pulse can quickly heat and evaporate the material, and can avoid the formation of the heat affected area.

3. Can quickly complete the drilling task, improve production efficiency, save time and cost.

4. High processing flexibility can be drilled in different shapes and sizes to achieve complex hole design and meet different processing needs.

Features:

Laser drilling is the use of laser beam thermal effect on the material processing, through the laser beam on the surface of the material to produce a high temperature area, so that the material local melting or vaporization, the formation of holes. Laser drilling is suitable for hole processing of various materials, including metals, plastics, ceramics, glass, etc., can achieve high precision, high efficiency, non-contact and non-mechanical damage advantages, widely used in electronics, automotive, aerospace, medical equipment and other fields.

Technical Parameters:

| Technical parameters | |

| Laser type |

Fiber Mopa

|

| Laser power | 120w , 180w |

| laser wavelength | 532nm |

| laser pulse width | 7ns@100KHz |

| Laser pulse frequency | 50-500KHz |

| Work Size | 800*800mm / 800*1000mm |

| Drilling Thickness | <20mm |

| Drilling Φ | <Φ100mm |

| Positioning Accuracy | ±0.02mm |

| Chipping | ≤200μm |

| Positional accuracy | ±3μm / ±5μm |

| Power | AC220V±5%,L+N+E,<3KW |

| Dimension | 1560mm × 1750mm × 1750mm / 1900mm ×1800mm × 1900mm |

| Weight | 1500kg |

![]()

Applications:

Independently developed cutting system , easy to learn and use , support a variety of cutting data formats dxf , dwg

Glass and ceramic products have been broadly used in many industries , such as household appliances , sanitary ware , decoration , optics , technology, and photovoltaic .

Besides , it has some practical application in construction , which is drilling of glass and ceramic products.

Comprising of different varieties , some of them includes ordinary glass , ultra white glass , K9 glass , stone British glass as well as high borosilicate glass etc .

Customization:

We offer laser drilling machine with brand name CKD and model number CC-G1. It is certified by ISO/CE/FDI. The minimum order quantity is 1 set and the price is negotiable. The packaging is wooden box and the delivery time is 15-45 days. The payment terms are L/C and T/T. We supply 50 sets per month. The repeatability is ±0.01mm. The power supply is 220V/50Hz. The dimension is 1560mm*1750mm*1750mm. The pulse energy is 2mJ and the repetition frequency is 20kHz.

Our laser drilling machine is perfect for glass drilling machine portable, laser micro drilling machine and glass drilling machine portable price. We have been manufacturing this product for many years and are confident that you will be satisfied with the quality. If you have any questions, please contact us. We look forward to working with you.

![]()

Support and Services:

Pre-Sales Service :

Demand analysis: Communicate with customers to understand their specific cutting needs, including material type, thickness, cutting accuracy requirements, output, etc., in order to customize the cutting machine to meet customer needs.

Technical consulting: To provide customers with relevant technical consulting services, including the advantages and disadvantages of different cutting technologies, scope of application, cost and other aspects of information, to help customers choose the most suitable cutting technology for their needs.

Technical scheme design: According to customer needs and actual situation, provide customers with customized cutting machine technical scheme design, including equipment configuration, process flow, production line layout, etc.

Prototype demonstration: To provide customers with customized cutting machine prototype demonstration, so that customers intuitively understand the performance and working effect of the equipment, so that customers can make a more accurate choice.

Pre-sales training: Provide customers with relevant cutting machine operation and maintenance training to help customers better understand the operation method and maintenance points of the equipment.

Packing and Shipping:

The Laser Drilling Machine is packaged to ensure safe delivery to your door. All components of the machine are securely packed in a durable cardboard box. The box is filled with foam padding to ensure that it will not move during shipping. The box is also labeled with the name of the product and a barcode.

The Laser Drilling Machine is shipped via a major courier company. The delivery time is dependant on the destination and the package size. Delivery is usually within 3-5 business days.

If you have any questions about the packaging and shipping of the Laser Drilling Machine, please contact us.

FAQ:

- Q : What is the machine warranty and after sale service?

- A : We will provide instruction videos and operation manuals to help you operate the machine. During covid19, we can provide whatsapp videos and WeChat online videos teach you how to use the machine step by step.

The machine has 1 years of after-sales service. During the warranty period, if there is any quality problem with the machine, we will replace with new parts and send it to you by express. Our freight. If there is any problem with the quality of the machine more than 1 years warranty, our after sales service team will help you solve it within 8 hours. - Q : Is this machine has quickly-wear part?

- A : The service life of the picosecond laser cutting machine is more than 100,000 hours, keeping better

work environment. Except for the damaged parts, no parts need to be replaced. -

Q : how can we guarantee quality?

A : Always a pre-production sample before mass production;

Always final Inspection before shipment;Q : what can you buy from us?

A : laser cutting machine,fiber laser cuttin,CO2 laser cutting machine,Welding machine,CNC router