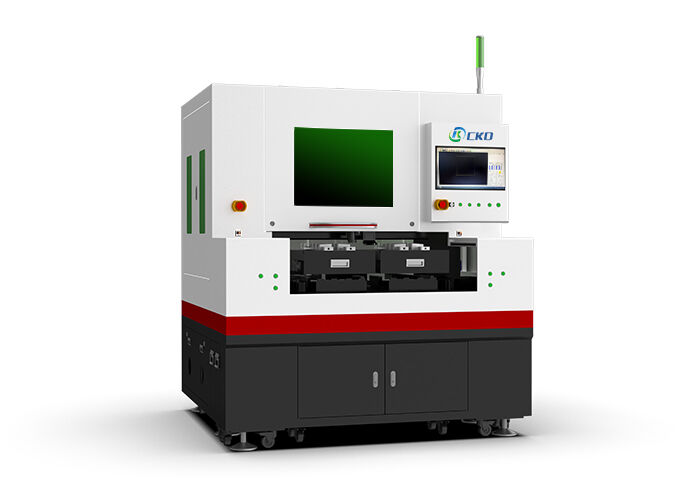

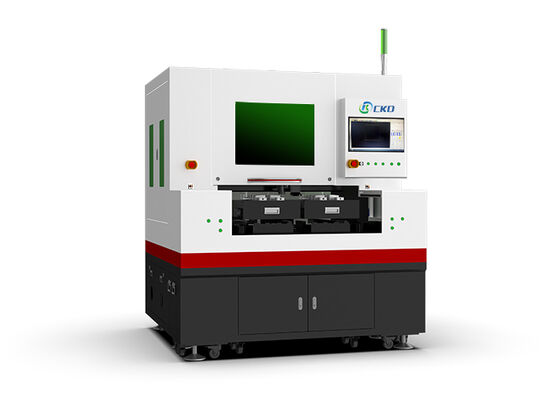

Glass Mirror Cutting Machine engineered to deliver consistent cutting and smooth edge finishing for glass and mirror products

-

Dimension1800*1700*2035mm

-

Cutting MethodLaser

-

Voltage220V/380V

-

MaterialGlass

-

Cutting Speed0-500mm/s

-

Cutting Thickness0.2-5mm

-

Cutting Accuracy±0.01mm

-

Cutting Size260x400mmx2

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO CE FDA IEC RoHS FCC UL

-

Model NumberCKD-DP3040C-50RE

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsWooden box

-

Delivery Time15-45 days

-

Payment TermsL/C, T/T

-

Supply Ability50 sets per month

Glass Mirror Cutting Machine engineered to deliver consistent cutting and smooth edge finishing for glass and mirror products

Product Description:

This device is an efficient cutting tool that uses high-energy lasers to cut glass. Its cutting process is mainly used for shape processing of glass, while using carbon dioxide laser to achieve glass cutting and segmentation. This device uses high-power picosecond laser as the light source and can provide customized services according to the needs of different customers to meet the cutting requirements of various rearview mirror glasses. The cutting accuracy is ± 0.01mm and the cutting speed is 0-500mm/s.![]()

![]()

![]()

Technical Parameters:

| Material | Glass |

| Cutting Angle | 0-45° |

| Cutting Speed | 0-500mm/s |

| Voltage | 220V/380V |

| Cutting Method | Laser |

| Motor Power | 3.5KW |

| Weight | 2000kg |

| Cutting Thickness | 0.2-5mm |

| Control System | HTI Control |

| Dimension | 1800*1700*2035mm |

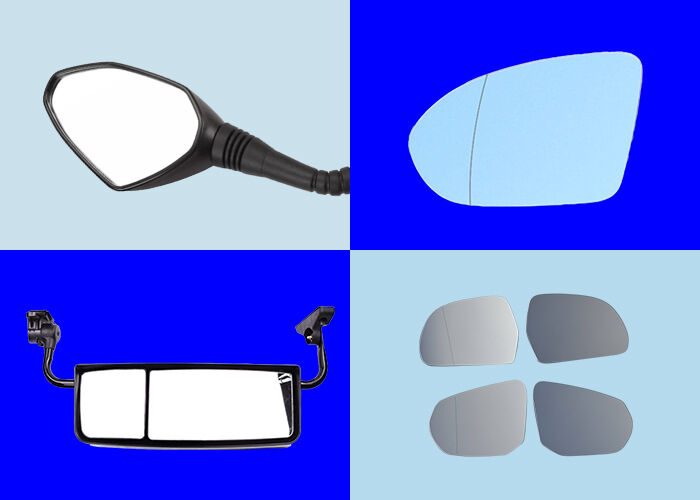

Applications:

Application materials: ultra-white glass, plain glass, etc.

Application products: car rearview mirror, electric car rearview mirror, motorcycle rearview mirror.

![]()

Introduction to the company:

Shenzhen CKD Precision Mechanical & Electrical Co., Ltd. was established in 2010. lt is a Ultrafast laser equipment manufacturer and automation new intelligent manufacturing solution provider that integrates R&D, production, sales, and service. After more than ten years of deep cultivation and accumulation, the company has accumulated more than 70 patents, passed CE certification,1S09001 quality management system certification, and Intellectual Property Management System Certification. lt is a national high-tech enterprise and a Shenzhen Professional, Refined, Special, and Innovation Enterprise.

The company has a sheet metal workshop, machining workshop, assembly workshop, and process development and debugging workshop, covering R&D, Production, Testing, Sale & after service.

Up to now, the company has strong R&D team that has been engaged in laser structural design and laser application technology for many years. With a strong R&D ability and core software technology, the company has achieved innovation and break-through in product technology in fields such as ultra fast laser cutting, laser drilling, TFT-LCD screen laser repair, semiconductor plastic sealing and debonding, diamond grinding, laser welding, and laser marking. Especially in the processing of hard and brittle materials such as glass and ceramics, TFT-LCD repair, semiconductor plastic sealing and debonding, as well as diamond grinding and other automated new intelligent manufacturing, we provide cus- tomers with low-cost, high-quality, and high-efficiency solutions,making contributions to customer with value-added,innovation,and development.

![]()

![]()

![]()

Packing and Shipping:

Product Packaging:

The Laser Glass Cutting Machine is carefully packaged using high-quality, durable materials to ensure maximum protection during transit. Each unit is wrapped in anti-static foam and secured within a sturdy wooden crate to prevent any damage from shocks or vibrations. The packaging is designed to be moisture-resistant and includes clear labeling for easy identification and handling instructions.

Shipping:

We offer reliable shipping options worldwide, utilizing trusted carriers to ensure timely and safe delivery of your Laser Glass Cutting Machine. The product is shipped with full insurance coverage, and tracking information is provided for every order. Our logistics team coordinates closely to manage customs clearance and handle all necessary documentation, guaranteeing a smooth and hassle-free shipping experience.

![]()