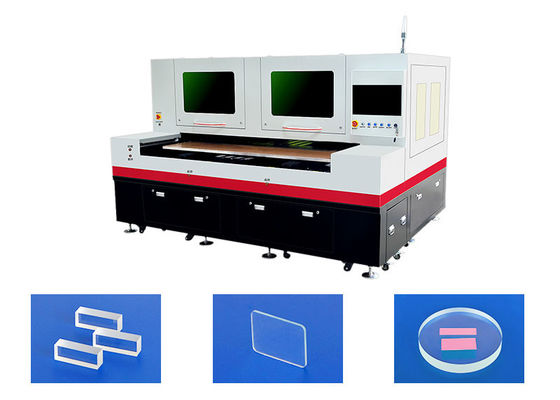

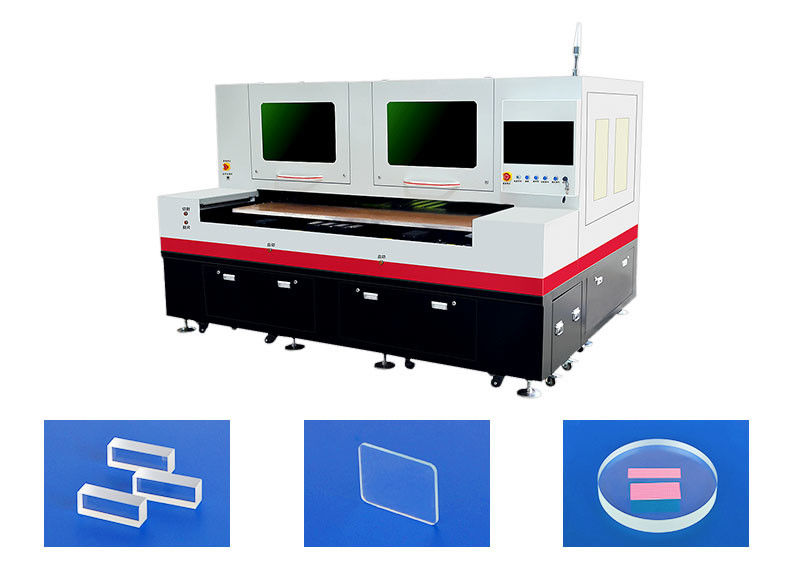

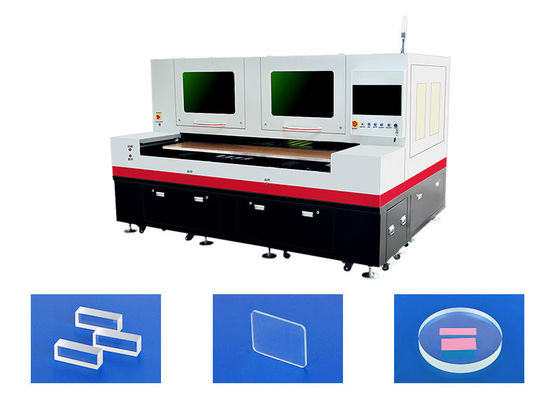

80W Large Size Fiber Laser Cutting Machine For Quartz Glass Cutting

-

Highlight

80W Fiber Laser Cutting Machine

,Large Size Fiber Laser Cutting Machine

,Fiber Laser Cutting Machine 80W

-

NameQuartz Glass Cutting Machine

-

Laser80W

-

Work Size1000*1000mm X 2

-

Cutting Accuracy±0.01mm

-

Cutting Thickness≤25mm

-

Cutting Speed1-500mm/s

-

Place of OriginChina

-

Brand NameCKD

-

CertificationISO / CE / FDI

-

Model NumberCC-GDA16

-

Minimum Order Quantity1

-

PriceNegotiated

-

Packaging DetailsPlywood Box

-

Delivery Time15-45 days

-

Payment TermsL/C, D/A, D/P, T/T

-

Supply Ability30 Sets Per Month

80W Large Size Fiber Laser Cutting Machine For Quartz Glass Cutting

80W Large Size Fiber Laser Cutting Machine

For Quartz Glass Cutting

Quartz glass compared with CNC processing equipment, brittle materials without taper picosecond laser cutting machine, no consumables in the production process, high production efficiency (cutting speed up to 500mm/s, several times the processing efficiency of CNC), for the processing manufacturers to save production costs, improve product profits.

This equipment is developed by the professional team of laser and automation industry for more than ten years. The equipment design uses high-quality imported durable parts, and the long-term production of the equipment is stable and reliable.

| Significant Attribute | |

| X/Y movement speed | max. 500mm/s |

| Laser type | Infrared picosecond |

| Laser wavelength | 1064nm |

| Laser power | 30W/50W/75W/80W optional |

| Pulse length | ≤10PS |

| Pulse frequency | 1Hz-1000kHz |

| Working mode | Laser XY moving |

| Cooling method | Water-cooled |

| Focusing mode | Cutting head |

| Focusing spot | ≤Ф3um |

| Cutting speed | Adjustable 1-500mm / s |

| Cutting thickness | according to the thickness of the glass to choose the number of laser W |

| Minimum cutting edge chipping | 6um |

| X / Y cutting stroke | 1000*1000mm*2 |

| X/Y positioning accuracy | ≤±2μm |

| X/Y repeat positioning accuracy | ≤±1um |

![]()

Applied Range

1 . Reinforced and non-reinforced glass cutting, such as: car Windows, mobile phone glass cover, car glass cover, camera glass cover, etc.;

2 . sapphire glass cutting, such as: mobile sapphire cover plate, camera sapphire glass cover plate, sapphire light strip (LED light strip);

3 . other optical glass cutting, such as: filter cutting, mirror cutting, etc.;

Cutting Principle

The picosecond laser beam is emitted at the transmission speed of <10ps pulse, after beam shaping and amplification, refracted to the cutting head, emitted <2um focused beam, acted on the material firmly adsorbed on the platform, the platform under the control of the high-precision motion controller at the upper position, according to the size pattern trajectory required by the customer to move, and then formed the cutting line. Complete the processing required by customers.

![]()

Basic configuration

1. The light source is a high-power picosecond laser, and the core components such as the core seed source are provided by the first-tier international manufacturers, which are stable in use

2.Exclusive glass cutting head, all lenses are imported from the United States, the spot is fine, the focal depth is long, the minimum focal spot is less than 2um, and the focal length can reach 15mm

3.The motor platform and the base of the optical platform are made of natural marble, which is processed by secondary fine grinding, and the accuracy level reaches 00.

4.X/Y axis motor adopts high-end linear motor, German 0.1um digital grating ruler, Taiwan screw rod and guide rail, high-quality core moving parts, 24 hours operation without failure

5.Adopt high negative pressure vacuum pump to absorb products to ensure positioning stability

6.The device aligns the CCD and telecentric vision lens to accurately identify Mark points such as circles and crosses

7.Electrical components adopt French Schneider, switching power supply adopts Taiwan Mingwei

FAQ

Q1: I don't know anything about this machine, what kind of machine should I choose?

Very easy to choose. Just tell us what you want to do with a picosecond glass cutter and let us provide you with the perfect solution and advice.

Q2: When I got this machine, I didn't know how to use it. what do I do?

We will send video and English manual to the machine. If you still have questions, we can chat by phone or via Skype and email.

Q3: What should I do if the machine has a problem during the warranty period?

If there is a problem with the machine, we will repair it for free during the machine warranty period. So if you have any questions, please let us know and we will provide you with a solution.

Q4: Before asking me about our fiber lasers, you'd better provide me with the following information

1) Your metal or non-metal material size. Because in our factory, we have different models according to the work area.

2) Your material.

Metal/Acrylic/Plywood/MDF/Glass?

Q5 : What after-sales service can be provided

1) 3 year guarantee for fiber laser cutting machine .

2) Full technical support by e-mail, call and video

3) Lifelong maintenance and spare parts supply.

4) Free design of fixtures as customers required.

5) Free training installation and operation for the staffs.